Casting techniques play a crucial role in metalworking by shaping molten metal into desired forms through molds, ensuring precise design replication and structural integrity. Different casting methods such as sand casting, investment casting, and die casting cater to specific production needs based on complexity and material properties. Discover how mastering casting can improve your manufacturing process by exploring the complete article.

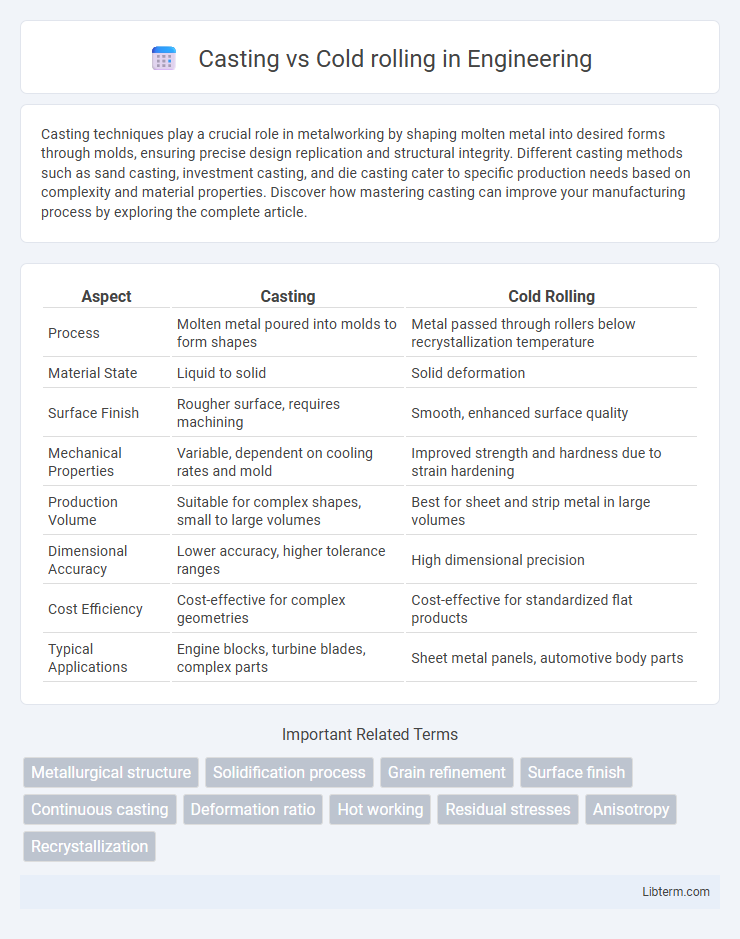

Table of Comparison

| Aspect | Casting | Cold Rolling |

|---|---|---|

| Process | Molten metal poured into molds to form shapes | Metal passed through rollers below recrystallization temperature |

| Material State | Liquid to solid | Solid deformation |

| Surface Finish | Rougher surface, requires machining | Smooth, enhanced surface quality |

| Mechanical Properties | Variable, dependent on cooling rates and mold | Improved strength and hardness due to strain hardening |

| Production Volume | Suitable for complex shapes, small to large volumes | Best for sheet and strip metal in large volumes |

| Dimensional Accuracy | Lower accuracy, higher tolerance ranges | High dimensional precision |

| Cost Efficiency | Cost-effective for complex geometries | Cost-effective for standardized flat products |

| Typical Applications | Engine blocks, turbine blades, complex parts | Sheet metal panels, automotive body parts |

Introduction to Casting and Cold Rolling

Casting involves pouring molten metal into molds to solidify into specific shapes, enabling the production of complex geometries and large components with minimal finishing requirements. Cold rolling is a metalworking process where metal sheets or strips are passed through rollers at room temperature, enhancing surface finish, dimensional accuracy, and mechanical properties such as strength and hardness. Both casting and cold rolling are essential in manufacturing, each offering distinct advantages based on application requirements and material characteristics.

Overview of Metal Forming Processes

Casting involves pouring molten metal into molds to achieve a specific shape, allowing for complex geometries but often requiring secondary machining. Cold rolling is a metal forming process where metal is passed through rollers at room temperature to improve surface finish, mechanical properties, and dimensional accuracy. Both processes are essential in manufacturing, with casting suited for initial shaping and cold rolling for refining metal characteristics and thickness.

What is Casting?

Casting is a manufacturing process where molten metal is poured into a mold to solidify into a specific shape, creating semi-finished or finished products. This method allows the production of complex shapes and large components with minimal mechanical processing. Casting is often used as a preliminary step before further treatments like cold rolling, which refines the metal's surface and enhances mechanical properties.

What is Cold Rolling?

Cold rolling is a metalworking process that involves deforming metal sheets at room temperature to improve surface finish, dimensional accuracy, and mechanical properties. Unlike casting, which solidifies molten metal into shape, cold rolling compresses and elongates the metal, resulting in increased strength and hardness due to work hardening. This process is commonly used for steel, aluminum, and copper to produce thin, smooth, and precise metal strips or sheets.

Key Differences Between Casting and Cold Rolling

Casting involves shaping metal by pouring molten material into molds, resulting in products with a coarser grain structure and potential surface imperfections. Cold rolling is a metalworking process that compresses metal sheets at room temperature, enhancing surface finish, dimensional accuracy, and mechanical strength through strain hardening. The key differences between casting and cold rolling lie in their temperature conditions, resulting microstructures, mechanical properties, and surface qualities, with casting primarily used for initial shaping and cold rolling for refining and strengthening metal products.

Advantages of Casting

Casting offers significant advantages such as the ability to produce complex shapes and large components in a single step, reducing manufacturing time and cost. It allows for greater design flexibility and material utilization, enabling the creation of parts with varied thicknesses and intricate internal geometries. Furthermore, casting is advantageous for producing metals and alloys that are difficult to shape through cold rolling, ensuring better control over the microstructure and mechanical properties.

Advantages of Cold Rolling

Cold rolling improves the surface finish and dimensional accuracy of metal products compared to casting, making it ideal for applications requiring tight tolerances. It enhances mechanical properties such as strength and hardness through strain hardening, which is not achievable via casting processes. The process also reduces porosity and internal defects, resulting in higher quality and more reliable metal components.

Limitations of Casting and Cold Rolling

Casting often faces limitations such as porosity, uneven microstructure, and size restrictions due to solidification defects. Cold rolling can be constrained by high residual stresses, dimensional tolerances, and limited thickness reduction per pass. Both processes require careful control to avoid defects that compromise mechanical properties and surface finish.

Applications in Industry

Casting is widely used in automotive and aerospace industries for producing complex shapes like engine blocks and turbine blades due to its ability to form large, intricate parts efficiently. Cold rolling is preferred in manufacturing sectors requiring high strength and surface finish, such as metal sheets for appliances, construction materials, and precision components in electronics. The choice between casting and cold rolling depends on the desired mechanical properties and dimensional accuracy for specific industrial applications.

Choosing Between Casting and Cold Rolling

Choosing between casting and cold rolling depends on the desired mechanical properties, surface finish, and dimensional precision of the final product. Casting allows for complex shapes and larger components with varying thickness, while cold rolling improves strength through work hardening and achieves tighter tolerances with smoother surfaces. Industries requiring high strength and fine surface details, such as automotive and aerospace, often prefer cold rolling, whereas casting suits applications needing intricate designs and bulk production.

Casting Infographic

libterm.com

libterm.com