Hazard and Operability Study (HAZOP) is a structured and systematic technique used to identify potential hazards and operability problems in industrial processes. It involves a detailed examination of the process design to uncover deviations from normal operation that could lead to safety risks or inefficiencies. Explore the rest of the article to understand how HAZOP can enhance your process safety and operational reliability.

Table of Comparison

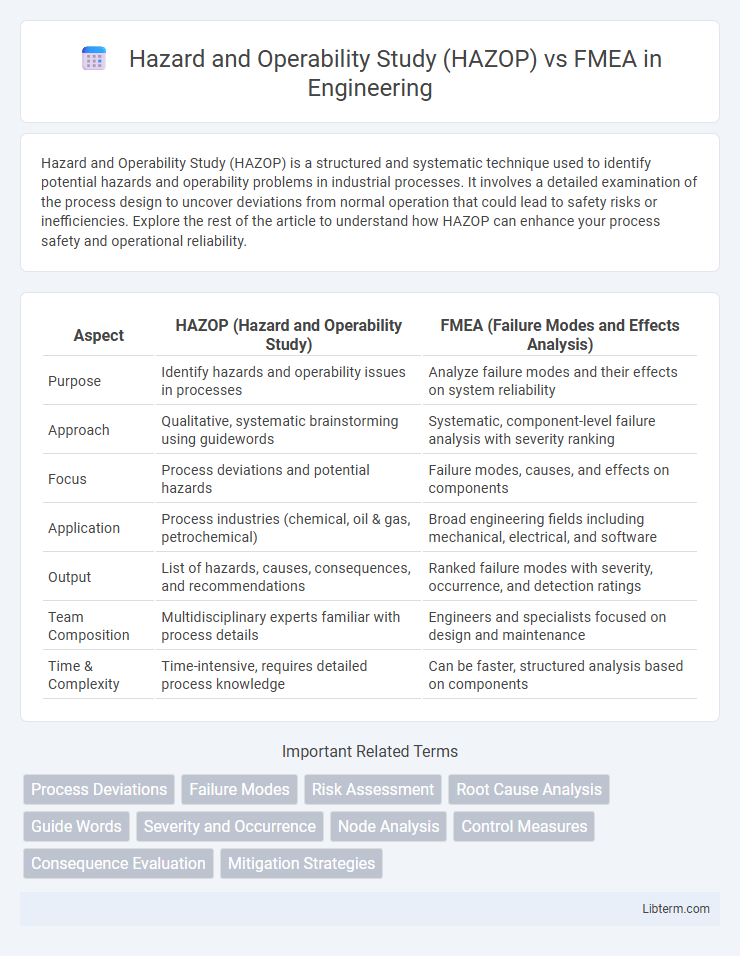

| Aspect | HAZOP (Hazard and Operability Study) | FMEA (Failure Modes and Effects Analysis) |

|---|---|---|

| Purpose | Identify hazards and operability issues in processes | Analyze failure modes and their effects on system reliability |

| Approach | Qualitative, systematic brainstorming using guidewords | Systematic, component-level failure analysis with severity ranking |

| Focus | Process deviations and potential hazards | Failure modes, causes, and effects on components |

| Application | Process industries (chemical, oil & gas, petrochemical) | Broad engineering fields including mechanical, electrical, and software |

| Output | List of hazards, causes, consequences, and recommendations | Ranked failure modes with severity, occurrence, and detection ratings |

| Team Composition | Multidisciplinary experts familiar with process details | Engineers and specialists focused on design and maintenance |

| Time & Complexity | Time-intensive, requires detailed process knowledge | Can be faster, structured analysis based on components |

Introduction to HAZOP and FMEA

Hazard and Operability Study (HAZOP) is a structured and systematic technique used primarily in process industries to identify potential hazards and operability problems by analyzing deviations from design intentions. Failure Modes and Effects Analysis (FMEA) systematically evaluates potential failure modes of components or systems to assess their impact on overall operation and prioritize mitigation actions. Both HAZOP and FMEA enhance safety and reliability but differ in scope, with HAZOP focusing on process deviations while FMEA targets individual failure modes.

Defining HAZOP: Principles and Process

HAZOP (Hazard and Operability Study) is a systematic, qualitative risk assessment method used to identify potential hazards and operability problems in industrial processes by examining deviations from design intent through guide words. The HAZOP process involves a multidisciplinary team conducting detailed, node-by-node brainstorming sessions to analyze process parameters such as flow, temperature, and pressure, ensuring comprehensive identification of risks. Emphasizing thorough documentation and targeted recommendations, HAZOP aims to enhance safety, reliability, and regulatory compliance in complex engineering systems.

Understanding FMEA: Key Concepts and Steps

Failure Modes and Effects Analysis (FMEA) systematically identifies potential failure modes within a system, assesses their causes and effects, and prioritizes risks based on severity, occurrence, and detection ratings. Key steps in FMEA include defining the scope, assembling a cross-functional team, listing all possible failure modes, analyzing their impact on system operations, and implementing corrective actions to mitigate identified risks. Unlike HAZOP which focuses on deviations from design intent, FMEA provides a detailed risk prioritization framework critical for enhancing reliability and safety in engineering processes.

Major Objectives: HAZOP vs FMEA

Hazard and Operability Study (HAZOP) primarily aims to identify potential hazards and operability problems in process plants by systematically examining process deviations using guide words. Failure Modes and Effects Analysis (FMEA) focuses on analyzing potential failure modes of components or systems to assess their effects on overall system reliability and safety. HAZOP targets process safety and operability risks, whereas FMEA emphasizes failure prevention and maintenance optimization.

Methodological Differences Between HAZOP and FMEA

HAZOP utilizes a systematic, guideword-based approach to identify potential hazards by examining deviations from design intents in process parameters, while FMEA adopts a component-level failure mode analysis to assess effects and prioritize risks based on severity, occurrence, and detection. HAZOP is typically applied in complex process industries, emphasizing process deviations and their consequences through multidisciplinary team workshops, whereas FMEA is commonly used in product design and manufacturing to evaluate specific failure modes and their impact on system reliability. The methodological distinction lies in HAZOP's focus on process parameter deviations with guidewords and qualitative risk assessment versus FMEA's structured failure mode identification and quantitative risk prioritization utilizing risk priority numbers (RPN).

Scope of Hazard Identification: HAZOP and FMEA

HAZOP primarily focuses on identifying potential deviations from design intent in chemical and process industries by systematically analyzing process parameters and their potential hazards. In contrast, FMEA emphasizes failure modes and their effects on system functions across various industries, including mechanical, electrical, and software systems. HAZOP targets operational hazards through guidewords to detect hazardous scenarios, while FMEA systematically ranks failure risks to prioritize mitigation efforts.

Application Areas in Industry

HAZOP is primarily applied in chemical processing, pharmaceutical manufacturing, and oil and gas industries to identify deviations in design and operation that could lead to hazards or operability issues. FMEA finds extensive use in automotive, aerospace, and electronics sectors, focusing on systematically identifying potential failure modes, their causes, and effects to improve product reliability and safety. Both methodologies enhance risk management but differ in their approach, with HAZOP emphasizing process flow deviations and FMEA targeting component-level failures.

Strengths and Limitations of HAZOP

HAZOP excels in identifying potential hazards and operability problems through a structured, team-based brainstorming process applied to detailed process flow diagrams, making it highly effective for complex chemical and industrial processes. Its strength lies in uncovering unexpected deviations and interactive failures, providing qualitative insights that consider human factors and process interactions. However, HAZOP is limited by its time-consuming nature, dependence on multidisciplinary team expertise, and difficulty in quantifying risk severity compared to the more quantitative Failure Modes and Effects Analysis (FMEA).

Strengths and Limitations of FMEA

FMEA (Failure Modes and Effects Analysis) excels at identifying potential failure modes, their causes, and effects in a systematic and quantitative manner, making it highly effective for prioritizing risks based on severity, occurrence, and detectability. It offers a structured approach suitable for early design stages and complex systems but is limited by its dependence on team expertise and may overlook hazards not tied to specific failure modes, unlike HAZOP which thoroughly examines deviations in process parameters. FMEA's limitations include difficulty handling complex interactions, potential underestimation of rare events, and less effectiveness in capturing operational hazards or process deviations without clear failure modes.

Choosing the Right Method: HAZOP vs FMEA

Choosing between HAZOP and FMEA depends on the specific risk analysis needs of a project, with HAZOP excelling at identifying potential hazards through detailed process examination and guideword prompts, while FMEA systematically evaluates component-level failure modes and their effects on system reliability. HAZOP is highly effective for complex chemical and process industries where deviations from design intent pose significant risks, whereas FMEA suits industries emphasizing mechanical, electrical, or design-related failure impacts in early development stages. Selecting the right method requires assessing whether the focus is on process deviations and operability issues (favoring HAZOP) or on failure mode impacts and prioritization for corrective actions (favoring FMEA).

Hazard and Operability Study (HAZOP) Infographic

libterm.com

libterm.com