Fillet welding is a common technique used to join two metal pieces at a right angle, creating a strong, triangular weld bead along the joint. This method provides excellent structural integrity in various applications, including construction and fabrication. Explore the rest of the article to discover how fillet welding can enhance the durability of your projects.

Table of Comparison

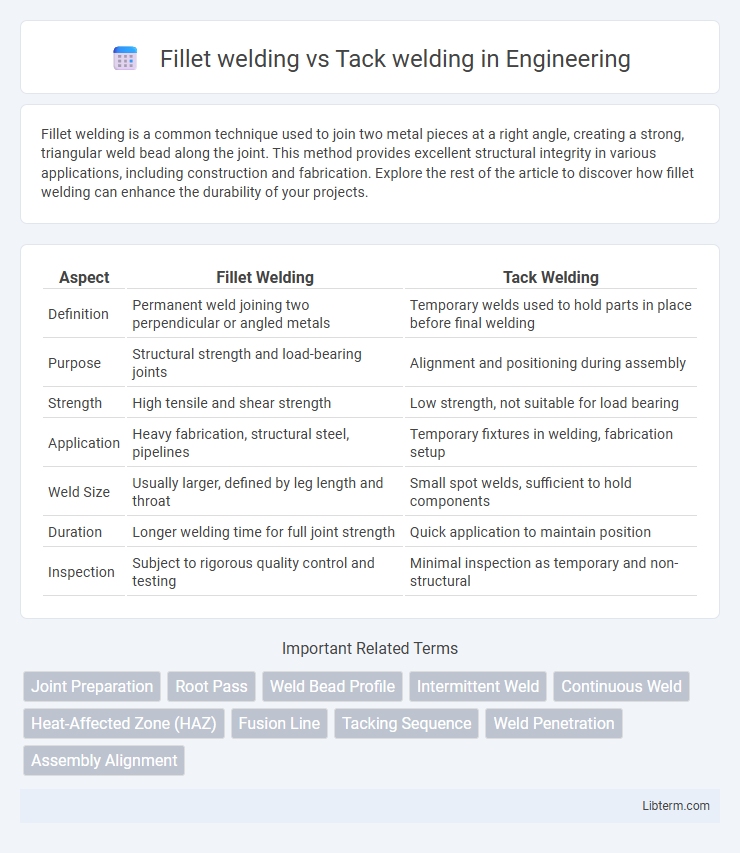

| Aspect | Fillet Welding | Tack Welding |

|---|---|---|

| Definition | Permanent weld joining two perpendicular or angled metals | Temporary welds used to hold parts in place before final welding |

| Purpose | Structural strength and load-bearing joints | Alignment and positioning during assembly |

| Strength | High tensile and shear strength | Low strength, not suitable for load bearing |

| Application | Heavy fabrication, structural steel, pipelines | Temporary fixtures in welding, fabrication setup |

| Weld Size | Usually larger, defined by leg length and throat | Small spot welds, sufficient to hold components |

| Duration | Longer welding time for full joint strength | Quick application to maintain position |

| Inspection | Subject to rigorous quality control and testing | Minimal inspection as temporary and non-structural |

Introduction to Fillet Welding and Tack Welding

Fillet welding is a common technique used to join two metal surfaces at a right angle by depositing weld material along the joint, creating a strong, triangular cross-section. Tack welding involves placing small, temporary welds to hold components in position before completing the final weld, ensuring alignment and stability. Both methods serve distinct roles in metal fabrication, with fillet welding providing structural strength and tack welding facilitating precise assembly.

Definition and Purpose of Fillet Welding

Fillet welding is a technique that joins two surfaces at approximately right angles by depositing a triangular cross-section of weld metal, commonly used to create strong, permanent joints in structural steel and fabrication. Its primary purpose is to provide robust connection and load-carrying capacity between parts such as beams and columns, offering enhanced mechanical strength and durability. Unlike tack welding, which temporarily holds components in place, fillet welding ensures a continuous, solid bond essential for the final integrity of welded assemblies.

Definition and Purpose of Tack Welding

Fillet welding is a technique used to join two surfaces at an approximate right angle, creating a triangular cross-section weld that provides structural strength. Tack welding involves placing small, temporary welds to hold parts in correct alignment before completing the final weld, ensuring precise positioning and minimizing distortion. The primary purpose of tack welding is to stabilize components during fabrication, allowing for adjustments and preventing movement throughout the welding process.

Key Differences Between Fillet Welding and Tack Welding

Fillet welding creates a permanent joint by fusing two surfaces at a right angle, ensuring structural integrity and strength, while tack welding serves as a temporary or preliminary weld that holds components in place before final welding. Fillet welds typically involve continuous or intermittent weld beads along the joint, whereas tack welds consist of small, spaced points applied to prevent movement or distortion. The key difference lies in the purpose and strength; fillet welding provides finished, load-bearing connections, whereas tack welding is primarily used for positioning and alignment during fabrication.

Common Applications of Fillet Welding

Fillet welding is commonly used in structural steel fabrication, shipbuilding, and bridge construction due to its ability to join perpendicular or angled metal components effectively. This welding technique provides strong, continuous joints ideal for load-bearing applications, making it essential in manufacturing frameworks, machinery, and automotive assembly. Unlike tack welding, which serves as a temporary hold, fillet welding delivers durable, final welds critical for safety and longevity in heavy-duty structures.

Common Applications of Tack Welding

Tack welding is commonly used to temporarily hold metal parts in place during the assembly of structures before performing the final welding operations, such as fillet welding. It ensures proper alignment and minimizes distortion in applications like frame construction, pipe fitting, and metal fabrication. This method is especially valuable in projects requiring precise joint positioning before completing robust, permanent welds.

Advantages of Fillet Welding

Fillet welding provides superior joint strength and durability compared to tack welding, making it ideal for load-bearing structures. It creates a continuous weld that ensures better resistance to fatigue and structural stress. The ability to form strong, permanent joints with consistent penetration enhances overall fabrication quality and reliability in construction and manufacturing applications.

Advantages of Tack Welding

Tack welding offers precise positioning and alignment of metal components, reducing the risk of distortion during the welding process. It allows for quick, temporary joins that secure parts before performing full welds, increasing overall efficiency and ease of adjustments. This technique minimizes material warping and saves time and resources in complex fabrication projects.

Choosing the Right Welding Method for Your Project

Fillet welding creates strong, permanent joints ideal for structural applications requiring high strength, while tack welding temporarily holds components in place for alignment before final welding. Selecting the right welding method depends on project requirements such as load-bearing capacity, precision, and production speed. Understanding the distinctions ensures optimal joint integrity and efficiency in fabrication or repair tasks.

Conclusion: Fillet Welding vs Tack Welding

Fillet welding provides strong, continuous joints essential for structural integrity, while tack welding offers temporary, spot welds ideal for positioning and alignment during fabrication. The choice between fillet and tack welding depends on the application's strength requirements and assembly stage. Fillet welding ensures long-term durability, whereas tack welding facilitates precise component fitting before final welding.

Fillet welding Infographic

libterm.com

libterm.com