A timing belt synchronizes the rotation of the crankshaft and camshaft, ensuring engine valves open and close at precise intervals for optimal performance. Regular inspection and timely replacement prevent engine damage, costly repairs, and maintain fuel efficiency. Discover how to identify timing belt issues and extend Your engine's lifespan by reading the rest of the article.

Table of Comparison

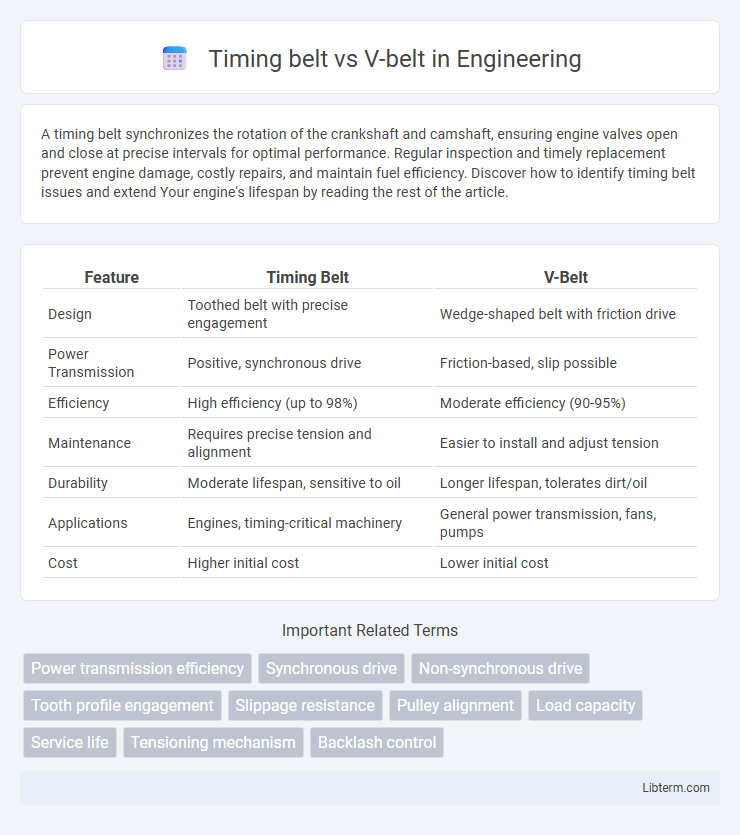

| Feature | Timing Belt | V-Belt |

|---|---|---|

| Design | Toothed belt with precise engagement | Wedge-shaped belt with friction drive |

| Power Transmission | Positive, synchronous drive | Friction-based, slip possible |

| Efficiency | High efficiency (up to 98%) | Moderate efficiency (90-95%) |

| Maintenance | Requires precise tension and alignment | Easier to install and adjust tension |

| Durability | Moderate lifespan, sensitive to oil | Longer lifespan, tolerates dirt/oil |

| Applications | Engines, timing-critical machinery | General power transmission, fans, pumps |

| Cost | Higher initial cost | Lower initial cost |

Overview of Timing Belts and V-Belts

Timing belts feature toothed design to synchronize engine camshaft and crankshaft movements precisely, ensuring accurate valve timing and improved engine performance. V-belts have a trapezoidal cross-section and transfer power through friction between the belt and pulley, commonly used in industrial machinery and automotive accessory drives. The choice between timing belt and V-belt depends on application-specific factors such as torque requirements, alignment precision, and maintenance intervals.

Key Differences Between Timing Belts and V-Belts

Timing belts feature precise toothed grooves that ensure synchronized rotation of engine components, preventing slippage and maintaining exact timing, essential in automotive and machinery applications. V-belts operate through friction in a V-shaped pulley groove, offering flexibility and smooth power transmission but are prone to wear and slip under high loads. Timing belts require specific alignment and tension settings for optimal performance, whereas V-belts provide easy installation and adjustment, making them suitable for varying power transmission needs.

Material Composition and Durability

Timing belts are typically made from reinforced rubber composites, incorporating materials like fiberglass or Kevlar for added tensile strength, which enhances durability and resistance to stretching. V-belts, constructed primarily from rubber and synthetic fibers with embedded tensile cords, offer flexibility but tend to wear faster under high-stress conditions compared to timing belts. The superior material composition of timing belts results in longer service life and precise mechanical performance, while V-belts require more frequent maintenance due to their susceptibility to slip and wear.

Power Transmission Efficiency

Timing belts provide superior power transmission efficiency compared to V-belts due to their positive engagement design, which reduces slippage and maintains precise speed ratios. V-belts transmit power through friction, leading to energy losses and decreased efficiency under high loads or misalignment. The consistent tension and synchronized movement of timing belts result in up to 98% efficiency, while V-belts typically achieve around 90-95% efficiency in similar applications.

Noise and Vibration Performance

Timing belts offer superior noise and vibration performance compared to V-belts due to their precise tooth engagement and reduced slippage, resulting in quieter and smoother operation. V-belts tend to generate more noise and vibrations because of their friction-based power transmission and potential for slip under load. Applications demanding minimal acoustic disturbance and vibration often prefer timing belts for enhanced efficiency and longevity.

Maintenance Requirements and Lifespan

Timing belts require precise maintenance intervals, typically replaced every 60,000 to 100,000 miles, as failure can cause significant engine damage. V-belts generally last between 40,000 to 70,000 miles and need regular inspections for wear, tension, and alignment to prevent slippage and reduce replacement frequency. Proper maintenance of timing belts involves timely tension adjustments and scheduled replacements, while V-belts benefit from frequent visual checks and tensioning to optimize lifespan.

Applications in Industry and Automotives

Timing belts provide precise synchronous power transmission, essential for applications in automotive engines where accurate camshaft timing is critical for optimal engine performance and fuel efficiency. V-belts, known for their flexibility and capability to handle high torque loads, are widely used in industrial machinery for driving pumps, compressors, and conveyors due to their durability and ease of maintenance. The choice between timing belts and V-belts depends on the required precision, load capacity, and environmental conditions specific to automotive and industrial applications.

Cost Comparison: Timing Belt vs V-Belt

Timing belts generally have a higher initial cost compared to V-belts due to their precise manufacturing and materials used for durability and performance in synchronous power transmission. V-belts offer a more economical option upfront, requiring less expensive replacement and simpler installation. Over time, timing belts can be more cost-effective in applications needing accurate timing and reduced maintenance, while V-belts may incur higher costs from more frequent adjustments and replacements.

Installation and Replacement Processes

Timing belts require precise alignment with camshaft and crankshaft pulleys during installation to maintain engine timing, while V-belts fit more flexibly around pulleys without strict timing constraints. Replacing timing belts involves removing engine covers and potentially other components, often demanding more labor and specific tools compared to V-belt replacement, which is generally quicker and simpler due to its straightforward pulley system. Proper installation of a timing belt is critical to prevent engine damage, whereas V-belt tension adjustments are essential to avoid slipping and wear.

Choosing the Right Belt for Your Needs

Choosing the right belt for your needs depends on the application's power transmission requirements and environmental conditions. Timing belts offer precise synchronization and are ideal for applications requiring accurate timing and minimal slippage, such as automotive engines and robotics. V-belts provide excellent flexibility and shock absorption, making them suitable for high-torque, low-speed machinery in industrial settings.

Timing belt Infographic

libterm.com

libterm.com