Chemical machining uses controlled chemical etching to remove material from metal surfaces with precision and minimal mechanical stress. This process is ideal for creating complex shapes and intricate patterns in metals like stainless steel, aluminum, and titanium. Explore the rest of the article to discover how chemical machining can optimize your manufacturing process.

Table of Comparison

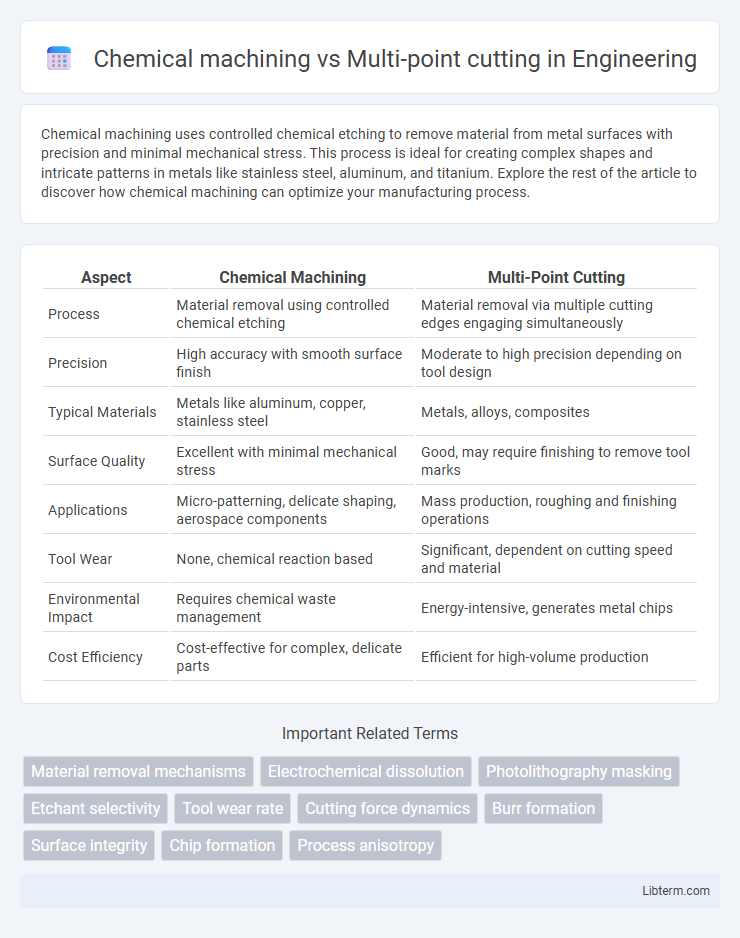

| Aspect | Chemical Machining | Multi-Point Cutting |

|---|---|---|

| Process | Material removal using controlled chemical etching | Material removal via multiple cutting edges engaging simultaneously |

| Precision | High accuracy with smooth surface finish | Moderate to high precision depending on tool design |

| Typical Materials | Metals like aluminum, copper, stainless steel | Metals, alloys, composites |

| Surface Quality | Excellent with minimal mechanical stress | Good, may require finishing to remove tool marks |

| Applications | Micro-patterning, delicate shaping, aerospace components | Mass production, roughing and finishing operations |

| Tool Wear | None, chemical reaction based | Significant, dependent on cutting speed and material |

| Environmental Impact | Requires chemical waste management | Energy-intensive, generates metal chips |

| Cost Efficiency | Cost-effective for complex, delicate parts | Efficient for high-volume production |

Introduction to Chemical Machining and Multi-Point Cutting

Chemical machining involves removing material through controlled chemical etching, allowing precise shaping of complex parts without mechanical stress or tool wear. Multi-point cutting uses a tool with multiple cutting edges to remove material efficiently, providing higher cutting rates and improved surface finish compared to single-point cutting. Chemical machining suits delicate or thin components, while multi-point cutting is ideal for mass production requiring rapid and consistent metal removal.

Basic Principles of Chemical Machining

Chemical machining relies on controlled chemical etching to remove material selectively by applying a resistant mask that protects certain areas while exposed regions dissolve in specific etchants. This process operates at the atomic or molecular level, ensuring precise material removal without mechanical stress or tool wear. Unlike multi-point cutting, which employs multiple cutting edges mechanically shearing material, chemical machining achieves intricate geometries through chemical reactions, making it ideal for thin, delicate, or complex workpieces.

Fundamentals of Multi-Point Cutting Processes

Multi-point cutting processes involve simultaneous material removal using multiple cutting edges, enhancing efficiency and surface finish in machining operations. Unlike chemical machining, which relies on controlled material dissolution through chemical reactions, multi-point cutting depends on mechanical forces and shear deformation. Fundamental principles include chip formation, cutting force distribution across the tool's edges, and heat generation management to optimize tool life and workpiece accuracy.

Material Compatibility and Selection Criteria

Chemical machining excels with materials sensitive to thermal or mechanical stresses, such as titanium and certain alloys, because it selectively removes material without inducing mechanical strain. Multi-point cutting is preferred for harder, more ductile materials like steel and aluminum alloys, offering precise dimensional control and faster material removal rates. Selection criteria hinge on material hardness, sensitivity to heat or mechanical stress, the complexity of the geometry, and desired surface finish quality.

Process Workflow: Chemical Machining vs Multi-Point Cutting

Chemical machining utilizes selective etching by applying acid-resistant masks to target areas, followed by controlled immersion in chemical baths to remove material precisely. Multi-point cutting involves simultaneous engagement of numerous cutting edges distributed over the tool body, enabling efficient material removal through mechanical deformation. Chemical machining offers high dimensional accuracy for complex geometries, whereas multi-point cutting excels in rapid material removal on less intricate surfaces.

Surface Finish and Dimensional Accuracy Comparison

Chemical machining produces highly uniform surface finishes by selectively removing material through controlled chemical reactions, resulting in minimal mechanical stress and distortion. Multi-point cutting methods achieve fine dimensional accuracy with precise tool paths but may introduce micro-scratches and tool marks affecting surface roughness. Chemical machining excels in maintaining consistent surface integrity, while multi-point cutting offers superior dimensional control for complex geometries.

Advantages and Limitations of Chemical Machining

Chemical machining offers precise material removal with minimal mechanical stress, enabling the production of complex shapes on delicate components. It provides uniform surface finishes and is advantageous for large-scale and thin materials where mechanical distortion is a concern. However, chemical machining is limited by slower material removal rates, environmental concerns related to chemical disposal, and difficulties in controlling etch depth on non-uniform surfaces.

Advantages and Limitations of Multi-Point Cutting

Multi-point cutting offers high material removal rates and improved surface finish due to the distribution of cutting forces across multiple cutting edges, reducing tool wear and increasing productivity in machining operations. It enables efficient machining of complex geometries and hard materials, with enhanced tool life and consistent dimensional accuracy. However, multi-point cutting tools can be expensive to manufacture and maintain, and may face limitations in machining very small or intricate features compared to single-point or chemical machining methods.

Typical Industrial Applications for Each Method

Chemical machining is predominantly used in aerospace and electronics industries for producing complex, thin metal parts and intricate circuit patterns due to its precision and ability to handle delicate materials. Multi-point cutting finds typical applications in automotive manufacturing and heavy machinery production where high-volume, robust metal removal is required for shaping gears, shafts, and engine components. Each method's suitability aligns with specific material properties and production scales, chemical machining serving delicate, precision tasks and multi-point cutting excelling in high-speed, large-scale metal shaping.

Economic and Environmental Considerations

Chemical machining offers cost advantages by reducing tooling expenses and enabling mass production with minimal material waste, making it economically efficient for complex shapes. Multi-point cutting, while potentially higher in tooling and maintenance costs, provides precise material removal and longer tool life, reducing operational downtime and overall expenses. Environmentally, chemical machining involves hazardous chemicals requiring careful disposal and can pose pollution risks, whereas multi-point cutting generates less chemical waste but may consume more energy and produce metal particulates needing proper handling.

Chemical machining Infographic

libterm.com

libterm.com