Dry friction occurs when two solid surfaces slide against each other without lubrication, generating resistance that opposes motion. This force plays a critical role in everyday activities, impacting everything from walking to vehicle braking systems. Explore the article to understand how dry friction affects your environment and its practical applications.

Table of Comparison

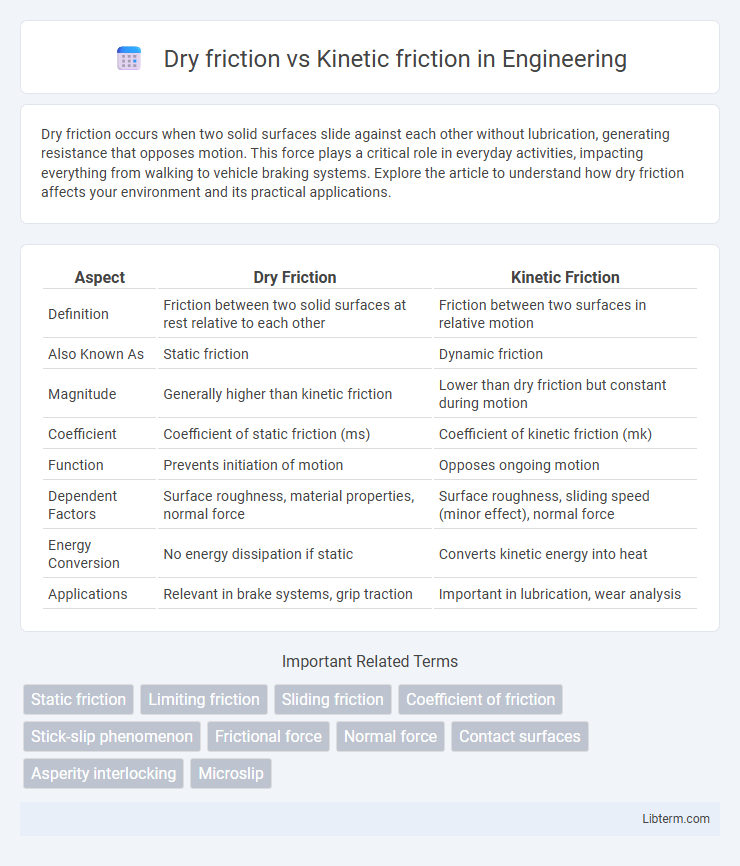

| Aspect | Dry Friction | Kinetic Friction |

|---|---|---|

| Definition | Friction between two solid surfaces at rest relative to each other | Friction between two surfaces in relative motion |

| Also Known As | Static friction | Dynamic friction |

| Magnitude | Generally higher than kinetic friction | Lower than dry friction but constant during motion |

| Coefficient | Coefficient of static friction (ms) | Coefficient of kinetic friction (mk) |

| Function | Prevents initiation of motion | Opposes ongoing motion |

| Dependent Factors | Surface roughness, material properties, normal force | Surface roughness, sliding speed (minor effect), normal force |

| Energy Conversion | No energy dissipation if static | Converts kinetic energy into heat |

| Applications | Relevant in brake systems, grip traction | Important in lubrication, wear analysis |

Introduction to Friction: Key Concepts

Dry friction occurs between two solid surfaces in contact without any lubrication, characterized by resistance to the initiation of motion, known as static friction, which is generally higher than kinetic friction. Kinetic friction acts during the relative motion of surfaces, offering a consistent resistive force that is usually lower than static friction, influencing energy dissipation and wear in moving mechanical systems. Understanding the distinction between these friction types is essential for designing efficient mechanisms and optimizing performance in engineering applications.

Defining Dry Friction

Dry friction occurs when two solid surfaces slide or attempt to slide across each other without the presence of lubricants or fluids, causing resistance. It encompasses both static friction, which prevents motion initiation, and kinetic friction, which acts during relative motion between surfaces. Kinetic friction specifically refers to the frictional force opposing the movement of sliding objects, generally lower in magnitude than static friction.

Understanding Kinetic Friction

Kinetic friction occurs when two surfaces slide against each other, causing resistance that slows the motion. This type of friction depends on the nature of the materials in contact and the normal force pressing them together, remaining relatively constant regardless of sliding speed. Understanding kinetic friction is crucial in engineering and physics for designing systems that minimize energy loss and improve mechanical efficiency.

The Physics Behind Dry and Kinetic Friction

Dry friction occurs when two solid surfaces resist relative motion without lubrication, relying on microscopic surface irregularities and interlocking asperities. Kinetic friction, acting during relative motion, involves the continuous breaking and reforming of microscopic junctions between surfaces, typically resulting in a lower frictional force compared to static dry friction. The coefficient of kinetic friction is generally constant and less than the coefficient of static (dry) friction, reflecting the different physical interactions at the interface during motion.

Differences Between Dry Friction and Kinetic Friction

Dry friction occurs between two solid surfaces in contact without relative motion, primarily resisting the initiation of movement, while kinetic friction acts on surfaces sliding past each other, opposing ongoing motion. Dry friction generally has a higher coefficient than kinetic friction, making it more effective at preventing motion than slowing it once started. The nature of dry friction is static and varies with surface roughness and normal force, whereas kinetic friction remains relatively constant during sliding at a specific velocity.

Factors Affecting Dry and Kinetic Friction

Surface roughness and material composition significantly influence dry friction, with rougher surfaces and harder materials generally increasing resistance. Kinetic friction depends on the relative velocity between surfaces and the presence of lubrication, which can reduce friction by forming a lubricating layer. Temperature and surface contaminants also affect both dry and kinetic friction by altering surface interactions and material properties.

Measurement and Calculation Techniques

Measurement of dry friction typically involves static friction tests using inclined planes or force sensors to determine the maximum force resisting motion before sliding begins, enabling calculation of the static friction coefficient. Kinetic friction measurement employs sliding tests where an object moves at constant velocity against a surface, with force sensors recording the resistive force to compute the kinetic friction coefficient. Calculations rely on the ratio of frictional force to the normal force, with precise instrumentation such as tribometers enhancing accuracy in both dry and kinetic friction evaluations.

Real-World Applications

Dry friction occurs between two solid surfaces in contact without lubrication, playing a crucial role in applications like brake systems where controlled stopping is essential. Kinetic friction acts on moving surfaces, significantly impacting the efficiency of machinery such as conveyor belts and vehicle tires by affecting energy consumption and wear rates. Understanding the differences between dry and kinetic friction is vital for optimizing performance and durability in automotive engineering and industrial manufacturing.

Challenges and Limitations

Dry friction presents challenges such as inconsistent resistance due to surface roughness and material wear, leading to unpredictable performance in mechanical systems. Kinetic friction introduces limitations by generating heat and energy loss during motion, which reduces efficiency and accelerates component degradation. Both types require careful material selection and surface treatment to optimize longevity and functionality in engineering applications.

Conclusion: Comparing Dry vs Kinetic Friction

Dry friction occurs between solid surfaces at rest, requiring greater force to initiate movement, while kinetic friction acts on surfaces in relative motion with typically lower resistance. The coefficient of dry friction is generally higher than that of kinetic friction, indicating more significant energy loss during the start of motion. Understanding these differences is crucial in mechanical design and engineering applications to optimize efficiency and control sliding interfaces.

Dry friction Infographic

libterm.com

libterm.com