Synchronous motors operate at a constant speed, synchronized with the frequency of the supply current, making them ideal for applications requiring precise speed control. These motors offer high efficiency and power factor correction benefits, enhancing overall system performance. Discover how a synchronous motor can improve your industrial or commercial applications by reading the rest of this article.

Table of Comparison

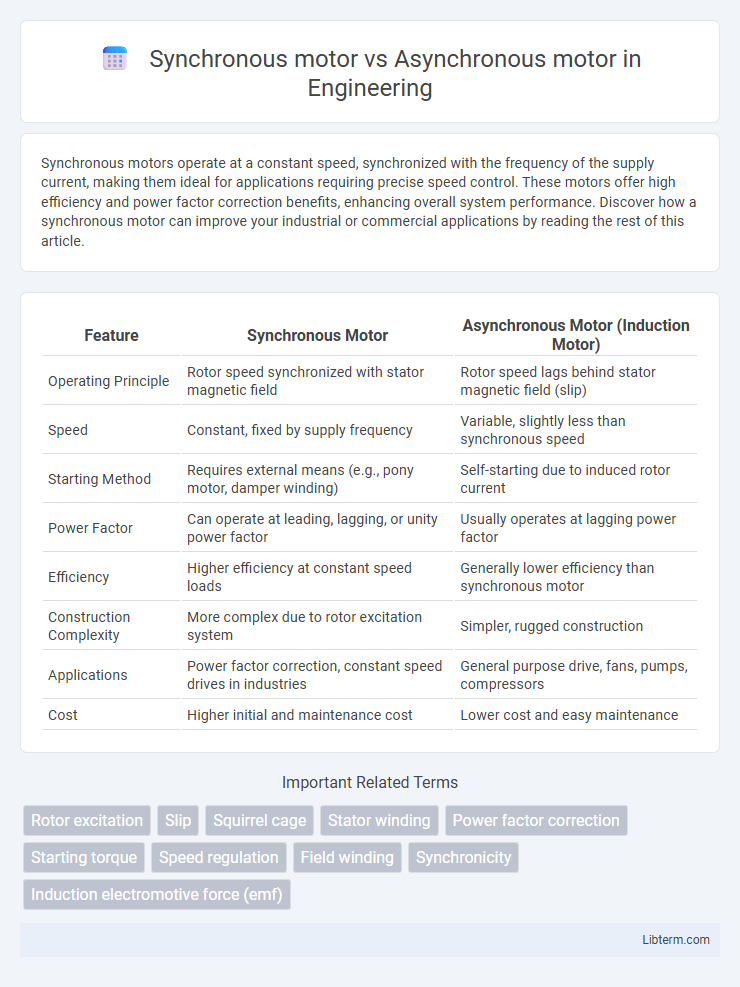

| Feature | Synchronous Motor | Asynchronous Motor (Induction Motor) |

|---|---|---|

| Operating Principle | Rotor speed synchronized with stator magnetic field | Rotor speed lags behind stator magnetic field (slip) |

| Speed | Constant, fixed by supply frequency | Variable, slightly less than synchronous speed |

| Starting Method | Requires external means (e.g., pony motor, damper winding) | Self-starting due to induced rotor current |

| Power Factor | Can operate at leading, lagging, or unity power factor | Usually operates at lagging power factor |

| Efficiency | Higher efficiency at constant speed loads | Generally lower efficiency than synchronous motor |

| Construction Complexity | More complex due to rotor excitation system | Simpler, rugged construction |

| Applications | Power factor correction, constant speed drives in industries | General purpose drive, fans, pumps, compressors |

| Cost | Higher initial and maintenance cost | Lower cost and easy maintenance |

Introduction to Synchronous and Asynchronous Motors

Synchronous motors operate at a constant speed synchronized with the supply frequency, making them ideal for precision applications requiring fixed speed. Asynchronous motors, also known as induction motors, run at a speed slightly less than the synchronous speed due to slip, offering robustness and cost-effectiveness for industrial use. Both motor types convert electrical energy into mechanical energy but differ in rotor construction and speed control mechanisms, influencing their application domains.

Basic Working Principle of Synchronous Motors

Synchronous motors operate by rotating at a constant speed synchronized with the supply frequency, where the rotor's magnetic field locks in step with the stator's rotating magnetic field. The rotor usually contains electromagnets energized by direct current, creating a fixed magnetic polarity that moves in unison with the stator's rotating field. This synchronization enables precise speed control and efficient operation in applications requiring constant speed under varying loads.

Basic Working Principle of Asynchronous Motors

Asynchronous motors operate based on the principle of electromagnetic induction where the rotor rotates at a speed slightly less than the synchronous speed of the stator's rotating magnetic field. This speed difference, known as slip, induces current in the rotor, generating torque and causing rotation. Unlike synchronous motors that require an external excitation, asynchronous motors self-induce the rotor current, making them simpler and more robust for general industrial applications.

Key Differences Between Synchronous and Asynchronous Motors

Synchronous motors operate at a constant speed synchronized with the supply frequency, while asynchronous motors (induction motors) run at a speed slightly less than the supply frequency due to slip. Synchronous motors require a DC excitation to the rotor for magnetic field creation, whereas asynchronous motors induce current in the rotor winding through electromagnetic induction. Synchronous motors offer precise speed control and higher efficiency, whereas asynchronous motors are simpler, more rugged, and widely used in industrial applications.

Construction and Design Comparison

Synchronous motors feature a rotor with permanent magnets or salient poles energized by direct current, enabling it to rotate at a constant speed synchronous with the supply frequency, while asynchronous motors (induction motors) have a squirrel-cage rotor or wound rotor that induces current through electromagnetic induction. The construction of synchronous motors includes slip rings and brushes for DC excitation in rotor windings, whereas asynchronous motors have a simpler design without slip rings or brushes, enhancing durability and reducing maintenance. The stator design in both motors is similar, but the rotor design difference significantly impacts performance characteristics and application suitability.

Performance Characteristics: Efficiency and Speed

Synchronous motors maintain constant speed under varying loads, offering high efficiency typically between 85% and 95%, ideal for precision applications. Asynchronous motors, or induction motors, experience slight speed slip under load, resulting in efficiency ranging from 75% to 90%, making them suitable for general industrial use. The consistent speed of synchronous motors enables better performance in tasks requiring precise speed control, whereas asynchronous motors provide robustness and cost-effectiveness in variable load conditions.

Applications of Synchronous Motors

Synchronous motors are extensively used in applications requiring precise speed control and constant speed operation, such as in robotics, conveyors, and printing machines. They are ideal for power factor correction in industrial plants due to their ability to operate at leading, lagging, or unity power factor. Their reliability in maintaining synchronous speed under varying load conditions makes them essential in applications like synchronous clocks and tachometers.

Applications of Asynchronous Motors

Asynchronous motors, commonly known as induction motors, are widely used in industrial applications due to their robust construction and reliability. They are ideal for driving pumps, fans, conveyors, and compressors where constant speed operation is required. These motors dominate sectors such as manufacturing, HVAC systems, and heavy machinery because of their low maintenance and cost-effectiveness.

Advantages and Disadvantages of Each Motor Type

Synchronous motors offer precise speed control and high efficiency, making them ideal for applications requiring constant speed under varying loads, but they require complex control systems and are generally more expensive to maintain. Asynchronous motors, or induction motors, are robust, cost-effective, and require less maintenance, with a simple design that performs well under variable load conditions, but they suffer from slip and less precise speed regulation. The choice between synchronous and asynchronous motors depends on the need for speed accuracy versus cost and durability in industrial applications.

Choosing the Right Motor for Industrial Applications

Selecting between synchronous and asynchronous motors depends on specific industrial requirements such as speed accuracy, load characteristics, and efficiency. Synchronous motors provide precise speed control and high efficiency at constant speeds, making them ideal for applications like conveyors and robotics where timing is critical. Asynchronous motors, also known as induction motors, offer robustness, lower cost, and simplicity, which are well-suited for heavy-duty operations such as pumps, fans, and compressors.

Synchronous motor Infographic

libterm.com

libterm.com