Model predictive control (MPC) is an advanced method used in process control that relies on dynamic models to predict future system behavior and optimize control inputs. This technique allows for handling multivariable control problems with constraints, making it ideal for complex industrial applications. Explore the rest of this article to understand how MPC can enhance your control strategies and improve system performance.

Table of Comparison

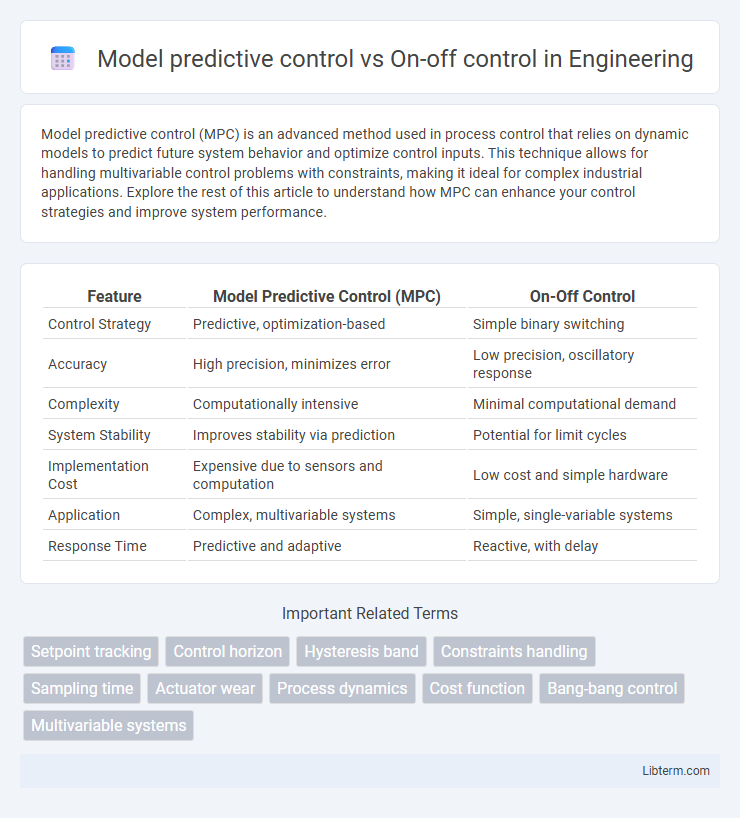

| Feature | Model Predictive Control (MPC) | On-Off Control |

|---|---|---|

| Control Strategy | Predictive, optimization-based | Simple binary switching |

| Accuracy | High precision, minimizes error | Low precision, oscillatory response |

| Complexity | Computationally intensive | Minimal computational demand |

| System Stability | Improves stability via prediction | Potential for limit cycles |

| Implementation Cost | Expensive due to sensors and computation | Low cost and simple hardware |

| Application | Complex, multivariable systems | Simple, single-variable systems |

| Response Time | Predictive and adaptive | Reactive, with delay |

Introduction to Control Strategies

Model Predictive Control (MPC) utilizes a dynamic model of the system to optimize control actions by predicting future behavior, enabling multivariable control and constraint handling. On-off control operates through a simple binary mechanism, switching actuators fully on or off based on set threshold values, making it suitable for systems where precision is less critical. MPC provides higher performance and efficiency in complex, nonlinear processes, whereas on-off control offers ease of implementation and robustness in basic applications.

Overview of Model Predictive Control (MPC)

Model Predictive Control (MPC) is an advanced control strategy that uses a dynamic process model to predict and optimize future system behavior over a finite horizon. It calculates control actions by solving an optimization problem at each time step, ensuring constraint satisfaction and improved performance compared to conventional On-off control. MPC is widely applied in complex industrial processes requiring multivariable control, such as chemical reactors, HVAC systems, and autonomous vehicles.

Fundamentals of On-Off Control

On-off control operates by switching the actuator fully on or off based on the deviation from a setpoint, offering simplicity and ease of implementation in systems requiring binary decisions. Model Predictive Control (MPC) anticipates future system behavior by solving an optimization problem over a receding horizon, enabling smoother and more precise control actions. The fundamental characteristic of on-off control is its reliance on threshold-based feedback, which often leads to oscillations around the setpoint and less efficient energy usage compared to predictive methods like MPC.

Key Differences Between MPC and On-Off Control

Model predictive control (MPC) uses a dynamic model to predict future system behavior and optimize control inputs over a specified horizon, resulting in smooth and precise control actions. On-off control, also known as bang-bang control, operates by switching actuators fully on or fully off based on threshold values, causing simple but often oscillatory responses. Key differences include MPC's ability to handle multi-variable systems and constraints proactively, whereas on-off control offers simplicity and low computational demand but lacks predictive capability and fine-tuned adjustments.

Performance Comparison in Dynamic Environments

Model predictive control (MPC) outperforms on-off control in dynamic environments by continuously optimizing control actions based on future system behavior predictions, resulting in enhanced stability and reduced overshoot. On-off control's binary nature leads to oscillations and delayed response under varying conditions, causing inefficiencies and potential system wear. MPC's ability to handle multivariable constraints and adapt to changing dynamics ensures superior performance in complex, time-varying processes.

Energy Efficiency and Cost Considerations

Model predictive control (MPC) optimizes energy efficiency by predicting future system behavior and adjusting inputs to minimize energy consumption, leading to significant cost savings in operation compared to on-off control. On-off control, characterized by simple binary switching, often results in higher energy use due to frequent start-stop cycles and overshooting, increasing operational costs and equipment wear. Implementing MPC can reduce energy bills by up to 20-30% in HVAC and industrial processes, whereas on-off control lacks the precision to achieve such cost-effective outcomes.

Implementation Complexity and Practical Challenges

Model predictive control (MPC) involves solving a constrained optimization problem at each sampling instant, which requires significant computational resources and advanced algorithms, making its implementation complex and resource-intensive. On-off control, characterized by simple threshold-based switching, is easy to implement with minimal computational demand but often suffers from steady-state oscillations and reduced control precision. Practical challenges of MPC include real-time model accuracy, tuning prediction horizons, and handling constraints, whereas on-off control faces challenges in managing chattering and limited adaptability to dynamic system changes.

Applications Best Suited for MPC

Model predictive control (MPC) is best suited for complex, multivariable systems requiring precise handling of constraints and prediction of future disturbances, such as chemical process control, autonomous vehicles, and energy management in smart grids. Unlike on-off control, which is ideal for simple, binary systems like thermostats or basic pump operations, MPC excels in optimizing performance and stability in dynamic, nonlinear environments. Its ability to anticipate system behavior and adjust control actions accordingly makes it indispensable in aerospace control systems and advanced robotics applications.

Applications Best Suited for On-Off Control

On-off control is best suited for applications with simple, binary operational states such as heating systems, refrigerators, and basic thermostats where precise modulation is unnecessary. This control method excels in cost-sensitive environments requiring straightforward implementation without complex sensor feedback or computation. Industrial processes that tolerate oscillations around setpoints and prioritize reliability and ease of maintenance also favor on-off control.

Future Trends in Industrial Control Systems

Model predictive control (MPC) offers advanced optimization and adaptability for complex industrial processes, enabling predictive adjustments based on dynamic system models, whereas On-off control remains simple and cost-effective for basic applications. Future trends in industrial control systems emphasize the integration of MPC with artificial intelligence and machine learning to enhance real-time decision-making and energy efficiency. The convergence of MPC with Industry 4.0 technologies will drive smarter, more autonomous factories with improved process stability and reduced operational costs.

Model predictive control Infographic

libterm.com

libterm.com