Composite construction combines steel and concrete to create structures that maximize strength and durability while minimizing material use. This method enhances load-bearing capacity and improves fire resistance, making it ideal for modern building projects. Discover how composite construction can revolutionize your next project by exploring the details in the rest of this article.

Table of Comparison

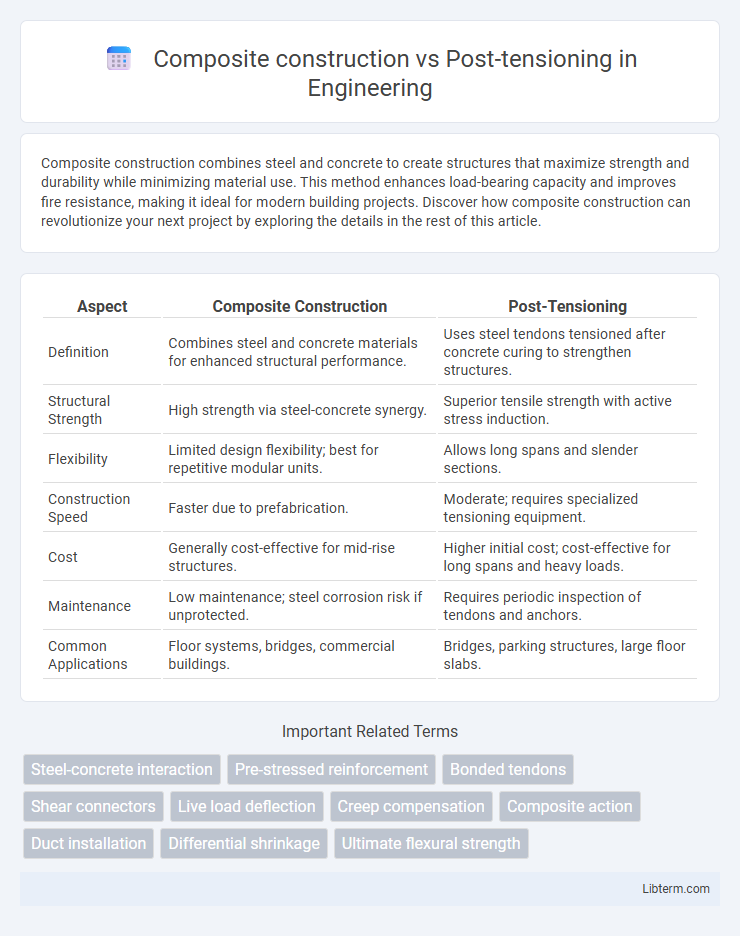

| Aspect | Composite Construction | Post-Tensioning |

|---|---|---|

| Definition | Combines steel and concrete materials for enhanced structural performance. | Uses steel tendons tensioned after concrete curing to strengthen structures. |

| Structural Strength | High strength via steel-concrete synergy. | Superior tensile strength with active stress induction. |

| Flexibility | Limited design flexibility; best for repetitive modular units. | Allows long spans and slender sections. |

| Construction Speed | Faster due to prefabrication. | Moderate; requires specialized tensioning equipment. |

| Cost | Generally cost-effective for mid-rise structures. | Higher initial cost; cost-effective for long spans and heavy loads. |

| Maintenance | Low maintenance; steel corrosion risk if unprotected. | Requires periodic inspection of tendons and anchors. |

| Common Applications | Floor systems, bridges, commercial buildings. | Bridges, parking structures, large floor slabs. |

Introduction to Composite Construction and Post-Tensioning

Composite construction merges steel and concrete to optimize structural performance by utilizing the strengths of both materials, enhancing load-bearing capacity and durability. Post-tensioning involves the application of tension to steel tendons within concrete after it has cured, increasing tensile strength and controlling deflection in slabs and beams. These methods improve structural efficiency, reduce material costs, and allow for longer spans in building and bridge construction.

Fundamentals of Composite Construction

Composite construction integrates steel and concrete to create a single structural system, enhancing load-bearing capacity and stiffness. Fundamental to composite construction is the interaction between steel beams and concrete slabs, typically connected using shear connectors to ensure composite action. This approach optimizes material efficiency and structural performance compared to traditional post-tensioning, which relies on tensioned tendons within concrete to control deflections and cracking.

Principles of Post-Tensioned Structures

Post-tensioned structures rely on tensioned steel tendons embedded within concrete to counteract tensile stresses, enhancing load-bearing capacity and reducing cracking. The tendons are tensioned after the concrete has gained sufficient strength, creating a compressive force that improves structural performance, especially in slabs and beams. This principle enables longer spans and thinner sections compared to traditional composite construction, where steel and concrete work together without active tendon tensioning.

Key Materials Used in Both Methods

Composite construction primarily utilizes steel and concrete to create a hybrid structural system where steel beams provide tensile strength and concrete slabs offer compressive resistance, enhancing load distribution. Post-tensioning relies on high-strength steel tendons embedded within concrete, which are tensioned after the concrete hardens to improve performance by controlling cracking and deflection. Both methods use concrete as a fundamental material, but composite construction integrates steel beams throughout, whereas post-tensioning focuses on internal steel tendons for active reinforcement.

Design Flexibility and Architectural Applications

Composite construction offers significant design flexibility due to its ability to integrate steel and concrete, allowing for varied shapes and aesthetic finishes that accommodate complex architectural forms. Post-tensioning enhances this flexibility by permitting longer spans, reduced slab thickness, and thinner floor profiles, which create open-plan spaces and innovative architectural applications. The combination of both techniques supports efficient load distribution and enables creative structural solutions tailored to modern building designs.

Structural Performance: Load Capacity and Durability

Composite construction offers enhanced structural performance by combining steel and concrete, resulting in increased load capacity and improved resistance to cracking under heavy loads. Post-tensioning significantly boosts durability by applying tension to steel tendons within concrete, reducing tensile stresses and controlling deflections, which extends the lifespan of structures. Both methods improve load-bearing capabilities, but post-tensioning provides superior control over serviceability and structural performance under dynamic and long-term loading conditions.

Construction Speed and Efficiency Comparison

Composite construction accelerates project timelines by integrating steel framing with concrete slabs, enabling simultaneous erection and pouring that reduces overall labor and material handling. Post-tensioning enhances efficiency through pre-stressing concrete elements, allowing longer spans with fewer supports, which minimizes formwork and scaffolding time. Together, these methods optimize construction speed by combining structural strength with streamlined workflows, significantly cutting down on project schedules.

Cost Analysis: Initial Investment and Lifecycle

Composite construction typically requires higher initial investment due to the integration of steel and concrete materials but offers lower maintenance costs over its lifecycle. Post-tensioning involves specialized tendons and tensioning equipment, raising upfront expenses, yet it enhances structural performance and reduces material volume, contributing to lower long-term operational costs. Lifecycle cost analysis favors post-tensioning in durability and reduced repair frequency, while composite construction benefits from quicker construction time minimizing labor costs.

Sustainability and Environmental Impact

Composite construction reduces environmental impact by combining steel and concrete, optimizing material use, and lowering overall carbon emissions through enhanced structural efficiency. Post-tensioning minimizes concrete volume and reinforcement needs, leading to less material consumption and decreased embodied energy in construction. Both methods contribute to sustainable building practices by improving durability and reducing resource demand, but post-tensioning often delivers greater material savings and waste reduction.

Choosing the Right Method: Factors and Case Studies

Choosing the right method between composite construction and post-tensioning depends on factors such as structural load requirements, span lengths, material costs, and project timeline constraints. Composite construction offers benefits in reducing dead load and increasing stiffness by combining steel and concrete, often ideal for medium spans, whereas post-tensioning enhances concrete performance for longer spans and heavier loads through prestressed tensioning of tendons. Case studies demonstrate that projects prioritizing rapid construction and flexibility often favor composite methods, while those demanding high load capacity and durability under dynamic conditions successfully implement post-tensioned systems.

Composite construction Infographic

libterm.com

libterm.com