Electrical balancing ensures equal voltage distribution across components, preventing overheating and enhancing efficiency in power systems. Proper balancing reduces energy losses and prolongs the lifespan of electrical devices by maintaining system stability. Discover how mastering electrical balancing can optimize your system's performance by reading the rest of the article.

Table of Comparison

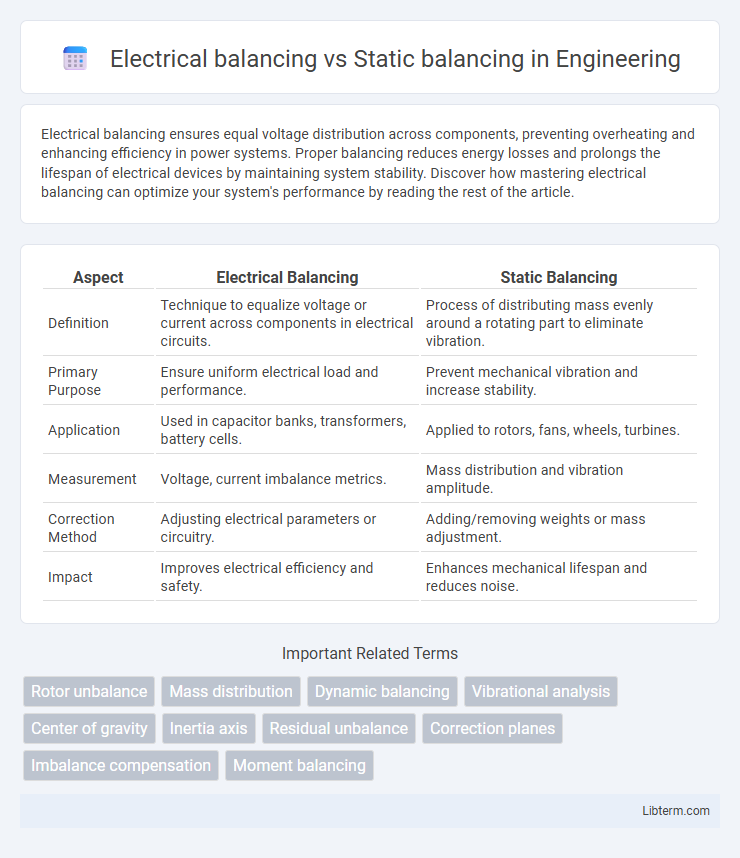

| Aspect | Electrical Balancing | Static Balancing |

|---|---|---|

| Definition | Technique to equalize voltage or current across components in electrical circuits. | Process of distributing mass evenly around a rotating part to eliminate vibration. |

| Primary Purpose | Ensure uniform electrical load and performance. | Prevent mechanical vibration and increase stability. |

| Application | Used in capacitor banks, transformers, battery cells. | Applied to rotors, fans, wheels, turbines. |

| Measurement | Voltage, current imbalance metrics. | Mass distribution and vibration amplitude. |

| Correction Method | Adjusting electrical parameters or circuitry. | Adding/removing weights or mass adjustment. |

| Impact | Improves electrical efficiency and safety. | Enhances mechanical lifespan and reduces noise. |

Introduction to Balancing Techniques

Electrical balancing involves adjusting the distribution of electrical properties, such as voltage or current, across components to achieve stability and efficiency in circuits. Static balancing refers to the process of evenly distributing mass or weight in rotating components like turbines or fans to prevent vibrations and mechanical wear. Both techniques are critical for optimizing performance and extending the lifespan of electrical and mechanical systems by minimizing imbalances that can cause operational issues.

What is Electrical Balancing?

Electrical balancing refers to the process of equalizing the electrical load or distribution within a system to ensure optimal performance and prevent imbalances that can cause inefficiencies or damage. It involves adjusting electrical parameters such as voltage, current, or phase angles to maintain system stability and reduce energy losses. Unlike static balancing, which physically balances rotating components, electrical balancing focuses on the management of electrical characteristics in circuits or machines.

What is Static Balancing?

Static balancing is the process of distributing mass around the center of gravity of a stationary rotating object to prevent it from wobbling when at rest. This technique ensures that the object's weight is evenly spread so that it remains stable and does not tip or rotate unexpectedly under gravitational forces. Static balancing is crucial in applications such as fan blades and industrial rotors where smooth and vibration-free operation is required.

Key Differences Between Electrical and Static Balancing

Electrical balancing involves adjusting the rotational dynamics of a system by controlling electrical factors such as current distribution and magnetic forces, ensuring optimal performance in electromechanical devices. Static balancing focuses on eliminating mass imbalances in a stationary object by redistributing weight to achieve uniform gravitational pull, primarily used in rotating machinery components like rotors and wheels. Key differences include the application context--electrical balancing is crucial in devices with active electromagnetic components, while static balancing pertains to mechanical mass distribution without reliance on electrical properties.

Applications of Electrical Balancing

Electrical balancing is widely applied in rotating machinery to reduce electromagnetic forces that cause vibrations, improving motor efficiency and extending bearing life. It is essential in high-speed electric motors, large generators, and precision instruments where dynamic electrical imbalances affect performance and reliability. Unlike static balancing, which addresses weight distribution and gravitational effects, electrical balancing specifically targets electromagnetic torque variations caused by rotor winding asymmetries.

Applications of Static Balancing

Static balancing is primarily used in applications where rotating parts need to remain stationary or rotate slowly, such as in ceiling fans, turbines, and small motors. It ensures that the center of gravity aligns with the axis of rotation, preventing vibrations and reducing wear in machinery by evenly distributing weight. This technique is crucial in precision instruments, automotive drive shafts, and aerospace components to maintain stability and prolong operational life.

Advantages of Electrical Balancing

Electrical balancing enhances rotor performance by dynamically correcting unbalanced forces during operation, leading to reduced vibration and extended machinery lifespan. It allows for real-time adjustments without dismantling equipment, improving maintenance efficiency and minimizing downtime. This method offers precise balance control, especially in high-speed rotating equipment, surpassing the limitations of static balancing.

Advantages of Static Balancing

Static balancing offers precise correction of mass distribution in rotating components, significantly reducing vibration and wear. It requires simpler equipment and less time compared to electrical balancing, enabling cost-effective maintenance and improved operational reliability. This method ensures consistent performance in applications with low to moderate rotational speeds, enhancing overall machine lifespan.

Limitations and Challenges of Each Method

Electrical balancing struggles with accuracy limitations due to sensitive equipment calibration and is challenged by electromagnetic interference affecting measurements. Static balancing faces difficulties in detecting unbalances at low rotational speeds and cannot address dynamic forces, limiting its effectiveness in complex rotating systems. Variability in operational conditions further complicates both methods, requiring complementary approaches for comprehensive rotor balancing.

Choosing the Right Balancing Technique

Choosing the right balancing technique depends on the application's requirements and the type of rotor involved. Electrical balancing uses sensors and electronic controls to dynamically correct imbalance during operation, making it ideal for high-speed machinery and precision equipment. Static balancing, which involves adjusting weight distribution on a stationary rotor, suits simpler applications with lower speed and less stringent vibration limits.

Electrical balancing Infographic

libterm.com

libterm.com