Non-destructive testing (NDT) is a crucial process used to evaluate materials, components, or assemblies without causing damage, ensuring their integrity and reliability. Techniques like ultrasonic testing, radiography, and magnetic particle inspection help detect flaws and prevent failures in critical applications. Discover how these methods protect your assets and improve safety by exploring the full article.

Table of Comparison

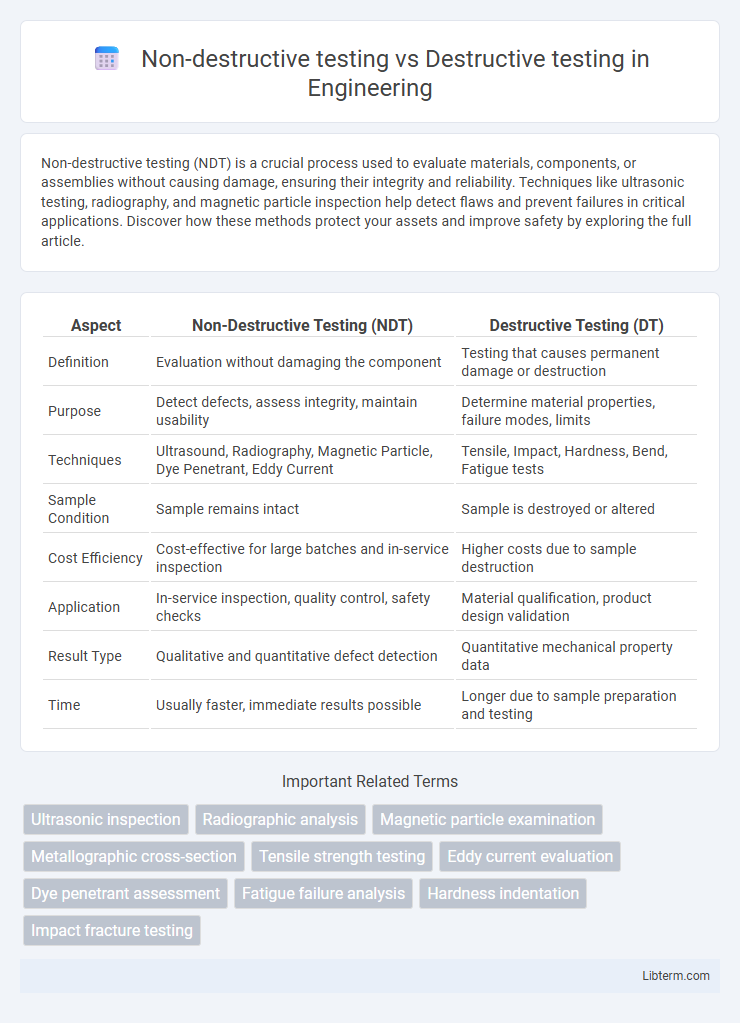

| Aspect | Non-Destructive Testing (NDT) | Destructive Testing (DT) |

|---|---|---|

| Definition | Evaluation without damaging the component | Testing that causes permanent damage or destruction |

| Purpose | Detect defects, assess integrity, maintain usability | Determine material properties, failure modes, limits |

| Techniques | Ultrasound, Radiography, Magnetic Particle, Dye Penetrant, Eddy Current | Tensile, Impact, Hardness, Bend, Fatigue tests |

| Sample Condition | Sample remains intact | Sample is destroyed or altered |

| Cost Efficiency | Cost-effective for large batches and in-service inspection | Higher costs due to sample destruction |

| Application | In-service inspection, quality control, safety checks | Material qualification, product design validation |

| Result Type | Qualitative and quantitative defect detection | Quantitative mechanical property data |

| Time | Usually faster, immediate results possible | Longer due to sample preparation and testing |

Introduction to Material Testing Methods

Non-destructive testing (NDT) evaluates material properties and detects defects without causing damage, preserving the sample for further use, while destructive testing involves applying force or stress to a specimen until failure to assess mechanical properties such as strength, ductility, and toughness. Common NDT methods include ultrasonic testing, radiographic testing, and magnetic particle inspection, offering rapid and accurate defect detection crucial for safety-critical industries. Destructive testing techniques like tensile, impact, and hardness tests provide comprehensive material characterization but render the sample unusable, necessitating careful selection based on application requirements.

What is Non-Destructive Testing (NDT)?

Non-Destructive Testing (NDT) is a vital inspection technique used to evaluate materials, components, or assemblies without causing damage, ensuring their integrity and serviceability. Common NDT methods include ultrasonic testing, radiography, magnetic particle inspection, and dye penetrant testing, each providing critical data on defects, cracks, or inconsistencies. NDT plays a crucial role in industries such as aerospace, automotive, and manufacturing by enabling early detection of potential failures while preserving the asset.

What is Destructive Testing (DT)?

Destructive Testing (DT) is an evaluation method where materials or components are deliberately subjected to conditions that cause permanent damage or failure to assess their mechanical properties, strength, and durability. This testing approach provides precise information about the material's behavior under stress, including fracture toughness, tensile strength, and fatigue limits. Unlike Non-Destructive Testing (NDT), DT renders the specimen unusable after examination, making it essential for validating design and ensuring safety in critical applications such as aerospace, construction, and automotive industries.

Key Differences Between NDT and DT

Non-destructive testing (NDT) evaluates material integrity without causing damage, preserving the object's usability, while destructive testing (DT) involves physically altering or destroying the sample to assess properties like tensile strength or fracture behavior. NDT methods, such as ultrasonic testing, radiography, and magnetic particle inspection, provide real-time inspection results, whereas DT techniques require specimen preparation and often longer analysis times. The cost-effectiveness and applicability to in-service inspection distinguish NDT from DT, which is primarily used during material qualification and failure analysis.

Common Techniques in Non-Destructive Testing

Common techniques in non-destructive testing (NDT) encompass ultrasonic testing (UT), radiographic testing (RT), magnetic particle testing (MT), and dye penetrant testing (PT), each offering effective flaw detection without damaging the material. Ultrasonic testing uses high-frequency sound waves to identify internal defects, while radiographic testing employs X-rays or gamma rays for detailed imaging of internal structures. Magnetic particle and dye penetrant testing enhance surface defect detection by utilizing magnetic fields and visible or fluorescent dyes, respectively, providing critical insights in maintenance and quality assurance.

Common Techniques in Destructive Testing

Common techniques in destructive testing include tensile testing, impact testing, hardness testing, and fatigue testing, each designed to evaluate material properties by physically damaging or breaking the sample. Tensile testing measures the strength and ductility by stretching the specimen until failure, while impact testing assesses toughness by subjecting the material to sudden force. Hardness testing determines resistance to indentation or scratching, and fatigue testing evaluates durability under cyclic loading conditions.

Advantages of Non-Destructive Testing

Non-destructive testing (NDT) preserves the integrity of materials and components, allowing them to remain in service without damage, which significantly reduces costs associated with repair and replacement. NDT techniques, such as ultrasonic, radiographic, and magnetic particle testing, provide immediate and accurate defect detection, ensuring safety and reliability in industries like aerospace, automotive, and manufacturing. The ability to perform inspections without material alteration increases efficiency by minimizing downtime and enables continuous maintenance and quality assurance throughout the product lifecycle.

Advantages of Destructive Testing

Destructive testing provides accurate and definitive results by physically evaluating material properties, structural integrity, and failure points through methods such as tensile, impact, or hardness tests. It enables engineers to verify design specifications, ensure safety standards, and improve product durability by analyzing real failure mechanisms under controlled conditions. This type of testing is essential for validating complex materials and components where non-destructive techniques may not reveal internal defects or long-term performance limitations.

Choosing the Right Testing Method for Your Application

Selecting the appropriate testing method depends on the application's requirements for material integrity and operational safety. Non-destructive testing (NDT) techniques like ultrasonic, radiographic, and magnetic particle testing allow for internal defect detection without compromising the specimen, making them ideal for in-service inspections. Destructive testing, such as tensile, impact, and fatigue tests, provides detailed material performance data but involves sample destruction, suitable for quality control during product development or failure analysis.

Future Trends in Material Testing

Future trends in material testing emphasize the integration of advanced non-destructive testing (NDT) techniques such as ultrasonic phased array, digital radiography, and infrared thermography, enabling precise defect detection without compromising sample integrity. The rise of artificial intelligence and machine learning algorithms enhances data analysis accuracy, facilitating real-time monitoring and predictive maintenance. Innovations in sensor miniaturization and IoT connectivity further support continuous health assessment of critical structures across aerospace, automotive, and civil engineering industries.

Non-destructive testing Infographic

libterm.com

libterm.com