A defect site refers to a specific location within a material or structure where imperfections, such as vacancies, dislocations, or impurities, disrupt its regular arrangement. These sites significantly impact the physical and chemical properties, influencing strength, conductivity, and reactivity. Explore the rest of the article to understand how defect sites affect your material's performance and how to manage them effectively.

Table of Comparison

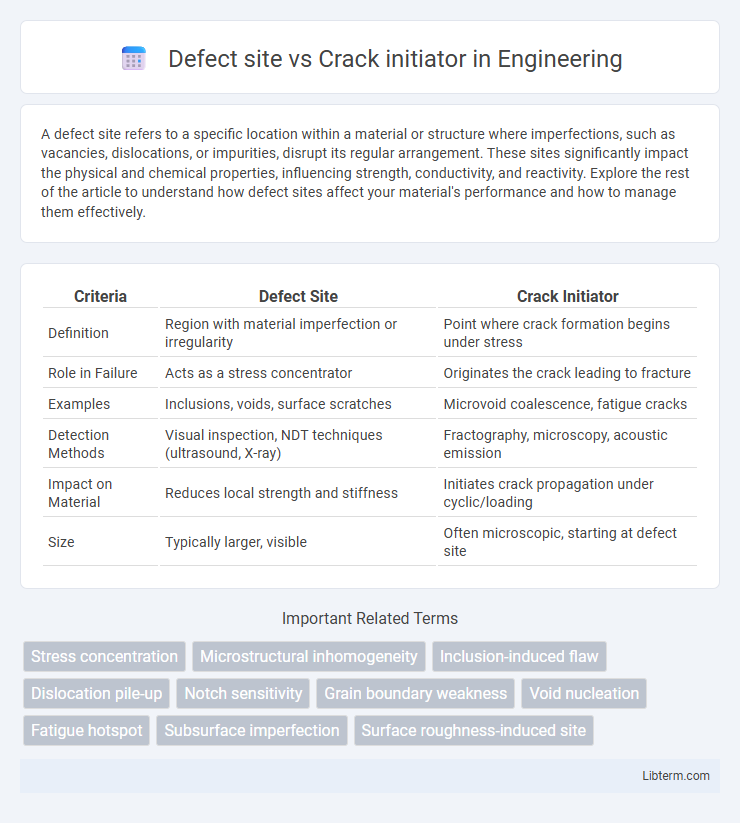

| Criteria | Defect Site | Crack Initiator |

|---|---|---|

| Definition | Region with material imperfection or irregularity | Point where crack formation begins under stress |

| Role in Failure | Acts as a stress concentrator | Originates the crack leading to fracture |

| Examples | Inclusions, voids, surface scratches | Microvoid coalescence, fatigue cracks |

| Detection Methods | Visual inspection, NDT techniques (ultrasound, X-ray) | Fractography, microscopy, acoustic emission |

| Impact on Material | Reduces local strength and stiffness | Initiates crack propagation under cyclic/loading |

| Size | Typically larger, visible | Often microscopic, starting at defect site |

Understanding Defect Sites in Materials

Defect sites in materials serve as localized disruptions in the crystal lattice, often acting as the primary crack initiators under stress. These defects--such as vacancies, dislocations, or inclusions--concentrate stress and reduce the material's inherent strength, accelerating crack nucleation. Understanding the nature and distribution of defect sites is crucial for predicting material failure and enhancing durability through targeted microstructural engineering.

What is a Crack Initiator?

A crack initiator is the specific point or location at which a crack begins to form in a material, often due to stress concentration or material defects. This site typically corresponds to microscopic discontinuities such as inclusions, voids, or corrosion pits that serve as stress risers, accelerating crack propagation. Understanding the crack initiator is crucial for predicting failure modes and improving material durability in engineering applications.

Key Differences: Defect Site vs Crack Initiator

A defect site refers to an inherent irregularity or imperfection within a material's microstructure, such as voids, inclusions, or grain boundary weaknesses, that can compromise its integrity. A crack initiator is the specific location where a crack begins to propagate, often originating at or near a defect site but can also arise from external factors like stress concentrations or surface damage. The key difference lies in that defect sites are material imperfections present before failure, while crack initiators are the precise points where fracture processes commence.

Common Types of Defect Sites

Defect sites commonly include voids, inclusions, and surface scratches, which serve as critical stress concentrators and significantly increase the likelihood of crack initiation in materials. Crack initiators often originate at these defect sites due to localized stress intensification and microstructural inhomogeneities. Understanding the nature and distribution of these defect types is essential for improving material durability and preventing premature failure.

Mechanisms of Crack Initiation

Defect sites act as stress concentrators where microstructural irregularities such as inclusions, voids, or grain boundaries initiate localized plastic deformation, leading to crack initiation under cyclic loading. Crack initiators arise from these defects when stress intensity exceeds material resistance, causing microcracks to nucleate and propagate perpendicular to the tensile stress direction. The mechanism of crack initiation involves the accumulation of dislocations and strain localization at the defect site, ultimately resulting in material failure through fatigue crack growth.

Influence of Microstructure on Crack Initiation

The microstructure significantly influences the distinction between defect sites and crack initiators by affecting stress concentration and localized deformation. Grain boundaries, phase distributions, and inclusions often act as primary defect sites where microstructural heterogeneities promote crack initiation. Understanding the interplay between these microstructural features and mechanical stresses is critical for predicting crack initiation locations and improving material fatigue resistance.

Role of Material Processing in Defect Formation

Material processing plays a critical role in defect site formation by influencing microstructural features such as grain boundaries, inclusions, and voids that act as stress concentrators. These inherent defects become primary crack initiators under mechanical loading due to localized stress intensification and material degradation. Advanced processing techniques like heat treatment and controlled solidification reduce defect density, thereby enhancing fatigue life by minimizing crack initiation sites.

Detection Methods for Defect Sites and Crack Initiators

Detection methods for defect sites and crack initiators primarily include non-destructive testing (NDT) techniques such as ultrasonic testing, radiography, and eddy current inspection, which identify subsurface and surface irregularities in materials. Advanced imaging methods like scanning electron microscopy (SEM) and digital image correlation (DIC) provide high-resolution analysis to pinpoint microstructural anomalies and stress concentration areas that often serve as crack initiation points. Acoustic emission monitoring detects real-time microcracking events, offering early warning on the evolution from defect sites to active crack initiation.

Preventive Strategies for Reducing Defects and Cracks

Defect sites and crack initiators significantly impact material integrity, requiring targeted preventive strategies to enhance durability. Implementing rigorous quality control during manufacturing, such as non-destructive testing and controlled cooling rates, reduces defect formation that can serve as crack initiators. Surface treatments like shot peening and coatings further mitigate crack propagation by improving surface hardness and resistance to environmental stressors.

Industrial Implications: Defect Sites vs Crack Initiators

Defect sites in industrial materials often serve as localized points of stress concentration, increasing the likelihood of fatigue failure. Crack initiators, a subset of these defects, directly contribute to the propagation of fractures under cyclic loading, critically impacting structural integrity and maintenance schedules. Identifying and mitigating defect sites before they evolve into crack initiators is essential for extending component lifespan and reducing downtime in manufacturing and heavy industries.

Defect site Infographic

libterm.com

libterm.com