PAC, or Political Action Committee, plays a pivotal role in fundraising and influencing elections by pooling contributions from members to support candidates or legislation. Understanding how PACs operate can help you navigate the complexities of political funding and advocacy more effectively. Explore the rest of this article to learn how PACs impact your political landscape.

Table of Comparison

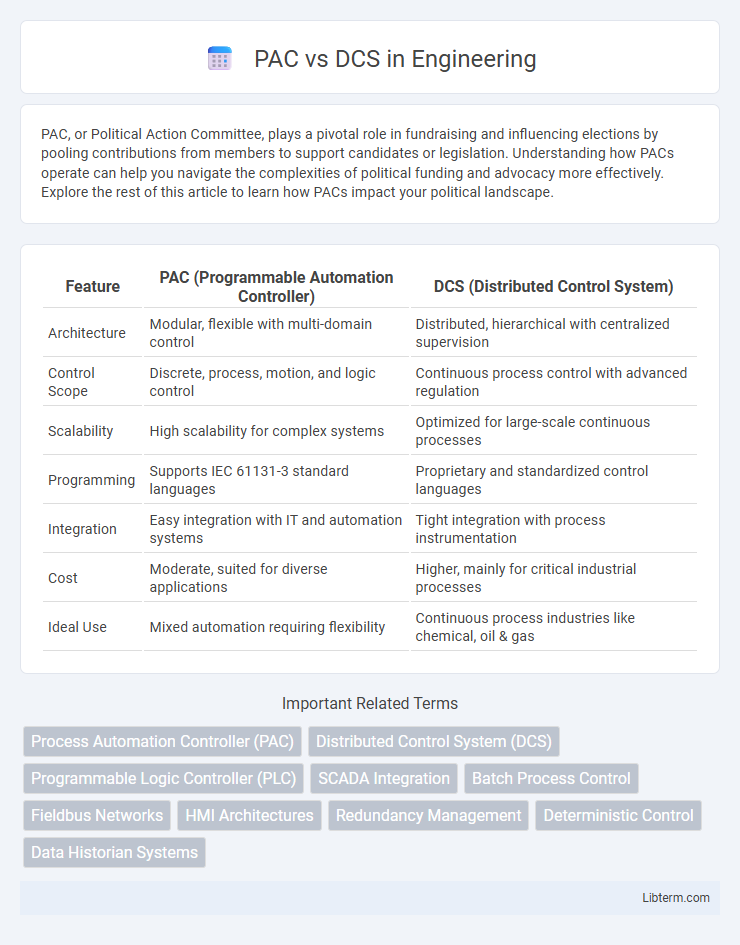

| Feature | PAC (Programmable Automation Controller) | DCS (Distributed Control System) |

|---|---|---|

| Architecture | Modular, flexible with multi-domain control | Distributed, hierarchical with centralized supervision |

| Control Scope | Discrete, process, motion, and logic control | Continuous process control with advanced regulation |

| Scalability | High scalability for complex systems | Optimized for large-scale continuous processes |

| Programming | Supports IEC 61131-3 standard languages | Proprietary and standardized control languages |

| Integration | Easy integration with IT and automation systems | Tight integration with process instrumentation |

| Cost | Moderate, suited for diverse applications | Higher, mainly for critical industrial processes |

| Ideal Use | Mixed automation requiring flexibility | Continuous process industries like chemical, oil & gas |

Introduction to PAC and DCS

Programmable Automation Controllers (PACs) combine the features of traditional Programmable Logic Controllers (PLCs) with advanced control, data acquisition, and communications capabilities, offering flexible and scalable solutions for complex industrial applications. Distributed Control Systems (DCS) focus on centralized control and monitoring of processes through a network of interconnected controllers, ideal for continuous, large-scale operations. PACs provide enhanced interoperability and programming flexibility, while DCS emphasizes reliability and seamless integration in process automation.

Overview of Process Automation Controllers (PACs)

Process Automation Controllers (PACs) integrate advanced control capabilities and data management into a single platform, bridging the gap between traditional Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS). PACs offer high-speed processing, complex logic control, and flexible communication options, making them ideal for diverse industrial automation applications requiring scalability and real-time data analytics. Their seamless interoperability with sensors, actuators, and enterprise systems enhances operational efficiency and enables predictive maintenance in process industries.

Understanding Distributed Control Systems (DCS)

Distributed Control Systems (DCS) provide centralized control with distributed elements, enabling scalable and reliable process automation in complex industrial environments. Unlike Programmable Automation Controllers (PAC), which focus on flexibility and integration of diverse control tasks, DCS emphasizes robust real-time control, fault tolerance, and seamless operator interface across multiple control loops. Understanding key components such as controllers, human-machine interfaces (HMI), and communication networks is essential for optimizing system performance and ensuring efficient process management.

Key Differences Between PAC and DCS

PAC (Programmable Automation Controller) integrates the flexibility of a PC with the robustness of a PLC, featuring advanced data processing, complex control algorithms, and seamless network communication. DCS (Distributed Control System) specializes in complex, continuous process control, offering hierarchical, modular architecture designed for high reliability and fault tolerance in large-scale industrial environments. Key differences include PAC's emphasis on versatile control and data handling for discrete and batch processes versus DCS's optimized structure for continuous process automation with distributed control nodes.

System Architecture Comparison

Programmable Automation Controllers (PACs) integrate features from both PLCs and PCs, offering a flexible, modular system architecture that supports complex control, data acquisition, and networking within a unified platform. Distributed Control Systems (DCS) employ a hierarchical and centralized architecture designed for large-scale, continuous processes, with multiple controllers communicating through robust networks to ensure system redundancy and reliability. PAC architectures emphasize open communication protocols and scalability for diverse applications, while DCS architectures prioritize tight integration and deterministic control in process industries.

Scalability and Flexibility Analysis

Programmable Automation Controllers (PACs) offer higher scalability and flexibility compared to Distributed Control Systems (DCS) due to their modular architecture and ability to integrate multiple control strategies across varied applications. PACs support a wide range of communication protocols and allow seamless system expansion, making them suitable for complex, evolving industrial processes. In contrast, DCS typically features fixed hardware configurations optimized for centralized process control, which can limit scalability and adaptability in dynamic production environments.

Integration Capabilities and Connectivity

Programmable Automation Controllers (PACs) offer superior integration capabilities with diverse industrial protocols such as Modbus, Ethernet/IP, and OPC UA, enabling seamless communication across multivendor systems. Distributed Control Systems (DCS) excel in process-centric connectivity, providing robust real-time data exchange and tight integration with proprietary field devices and control modules. PACs emphasize flexibility and scalability for complex automation networks, while DCS prioritize reliability and deterministic control within integrated process environments.

Cost Considerations: PAC vs DCS

PAC systems generally offer lower upfront costs due to modular hardware and flexible software configurations, making them ideal for smaller or customized applications. DCS solutions often involve higher initial investment because of integrated components and comprehensive control capabilities tailored for large-scale industrial processes. Maintenance expenses for PACs tend to be lower due to simplified architectures, whereas DCS systems may incur greater long-term costs driven by proprietary technologies and extensive support requirements.

Industry Applications and Use Cases

Programmable Automation Controllers (PACs) are widely used in complex manufacturing processes requiring high-speed data acquisition, advanced control algorithms, and seamless communication across heterogeneous systems, making them ideal for industries like automotive and aerospace. Distributed Control Systems (DCS) excel in continuous process industries such as oil refining, chemical production, and power generation by offering robust process automation, real-time monitoring, and centralized control over distributed field devices. The choice between PAC and DCS depends on the specific application needs, with PACs favoring discrete and batch processing environments, while DCS suits large-scale, continuous process control scenarios.

Choosing the Right Solution: PAC or DCS?

Choosing between a Programmable Automation Controller (PAC) and a Distributed Control System (DCS) depends on application complexity, scalability, and integration needs. PACs offer flexible, high-speed control suited for discrete manufacturing and complex data handling, while DCS excels in continuous processes with seamless control and monitoring across large plants. Evaluating factors like system openness, real-time performance, and existing infrastructure ensures selecting the optimal automation platform for operational efficiency and future growth.

PAC Infographic

libterm.com

libterm.com