Magnetic bearings use magnetic fields to support rotating shafts without physical contact, reducing friction and wear while enabling high-speed operation and greater efficiency. Their design allows for precise control and maintenance-free performance in applications ranging from industrial turbines to advanced machinery. Discover how magnetic bearings can transform your engineering projects by exploring the detailed insights in this article.

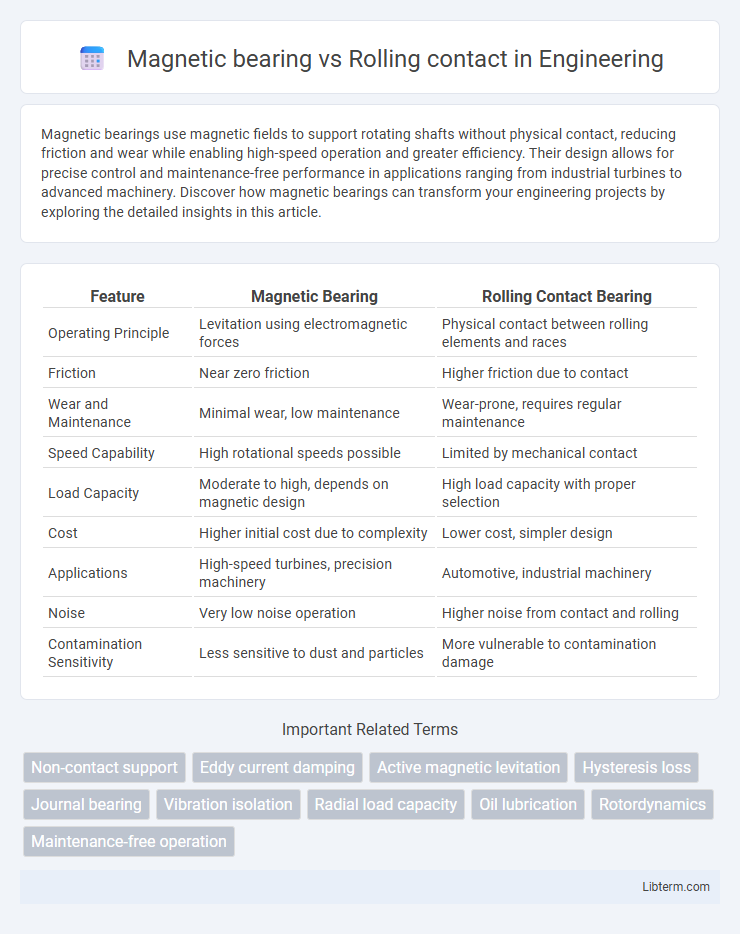

Table of Comparison

| Feature | Magnetic Bearing | Rolling Contact Bearing |

|---|---|---|

| Operating Principle | Levitation using electromagnetic forces | Physical contact between rolling elements and races |

| Friction | Near zero friction | Higher friction due to contact |

| Wear and Maintenance | Minimal wear, low maintenance | Wear-prone, requires regular maintenance |

| Speed Capability | High rotational speeds possible | Limited by mechanical contact |

| Load Capacity | Moderate to high, depends on magnetic design | High load capacity with proper selection |

| Cost | Higher initial cost due to complexity | Lower cost, simpler design |

| Applications | High-speed turbines, precision machinery | Automotive, industrial machinery |

| Noise | Very low noise operation | Higher noise from contact and rolling |

| Contamination Sensitivity | Less sensitive to dust and particles | More vulnerable to contamination damage |

Introduction to Magnetic Bearings and Rolling Contact Bearings

Magnetic bearings use magnetic fields to levitate and support rotating shafts without physical contact, enabling frictionless operation and reduced wear compared to traditional rolling contact bearings. Rolling contact bearings rely on rolling elements such as balls or rollers positioned between inner and outer rings to carry loads and facilitate rotation with minimal friction. The absence of mechanical contact in magnetic bearings results in higher precision, longer lifespan, and cleaner operation, especially in high-speed and sensitive applications.

Working Principles of Magnetic Bearings

Magnetic bearings operate by using electromagnetic forces to levitate a rotor without physical contact, eliminating friction and wear typical in rolling contact bearings. They rely on sensors and control systems to continuously adjust magnetic fields, maintaining rotor stability and position within the bearing gap. In contrast to rolling contact bearings that use balls or rollers to support loads, magnetic bearings provide near-frictionless rotation and can operate in extreme conditions with minimal maintenance.

How Rolling Contact Bearings Operate

Rolling contact bearings operate by utilizing rolling elements, such as balls or rollers, positioned between two rings called races. These elements reduce friction by rolling instead of sliding, supporting radial and axial loads while allowing smooth rotational motion. Precise lubrication and material selection enhance durability and minimize wear in demanding applications.

Key Advantages of Magnetic Bearings

Magnetic bearings offer key advantages over rolling contact bearings, including virtually frictionless operation and minimal mechanical wear, which leads to longer service life and reduced maintenance costs. Their ability to operate in extreme environments, such as high speeds and vacuum conditions, provides unmatched reliability and precision in critical applications like turbines and high-speed compressors. The contactless nature of magnetic bearings eliminates lubrication needs, enhancing energy efficiency and reducing contamination risks significantly.

Benefits of Rolling Contact Bearings

Rolling contact bearings offer significant benefits including high load capacity, low friction, and proven reliability in various industrial applications. They provide cost-effective maintenance and durability under harsh operating conditions, making them suitable for heavy machinery and automotive uses. Compared to magnetic bearings, rolling contact bearings deliver simpler installation and less complex control systems.

Comparative Performance: Speed, Load, and Efficiency

Magnetic bearings outperform rolling contact bearings by offering higher speed capabilities due to reduced friction and absence of mechanical contact, enabling rotational speeds beyond 100,000 RPM. They handle dynamic loads effectively with precision control and minimal wear, though rolling contact bearings typically support higher static loads and more robust shock resistance. In terms of efficiency, magnetic bearings achieve lower energy loss and maintenance costs, enhancing overall system reliability and lifespan in high-performance applications.

Maintenance Requirements and Reliability

Magnetic bearings offer superior reliability due to the absence of physical contact, significantly reducing wear and maintenance needs compared to rolling contact bearings. Rolling contact bearings require regular lubrication, inspection, and periodic replacement to prevent failure from friction and material fatigue. The non-contact nature of magnetic bearings extends operational life and decreases downtime, making them ideal for high-precision, high-speed applications where maintenance access is limited.

Common Applications for Each Bearing Type

Magnetic bearings are widely used in high-speed machinery such as turbo compressors, flywheel energy storage systems, and vacuum pumps due to their frictionless operation and precision control. Rolling contact bearings find common applications in automotive wheels, electric motors, and industrial conveyors where durability and load capacity are critical. Each bearing type addresses specific operational demands, with magnetic bearings excelling in environments requiring low maintenance and high-speed dynamics, while rolling contact bearings provide reliable performance under heavy loads and moderate speeds.

Cost Considerations and Lifecycle Analysis

Magnetic bearings generally have higher initial costs due to advanced materials and complex control systems, while rolling contact bearings are more economical upfront with well-established manufacturing processes. Lifecycle analysis shows magnetic bearings offer lower maintenance expenses and longer service life because they operate without physical contact, reducing wear and downtime. Despite higher capital investment, magnetic bearings often yield cost savings over time through energy efficiency and reduced replacement needs compared to rolling contact counterparts.

Future Trends in Bearing Technology

Magnetic bearings leverage electromagnetic fields to eliminate physical contact, significantly reducing friction and wear compared to rolling contact bearings. Future trends emphasize advancements in smart magnetic bearing systems integrated with IoT sensors for real-time monitoring and predictive maintenance. Increased adoption of magnetic bearings in high-speed, precision applications such as aerospace and renewable energy highlights their growing role in next-generation bearing technology.

Magnetic bearing Infographic

libterm.com

libterm.com