A cruciform joint is a type of mechanical joint characterized by its cross-shaped configuration, often used to connect multiple components at right angles for enhanced stability and load distribution. These joints are essential in construction and manufacturing where precise alignment and strength are crucial, providing durability in frameworks and machinery. Explore the article to discover how cruciform joints can improve the integrity of your projects.

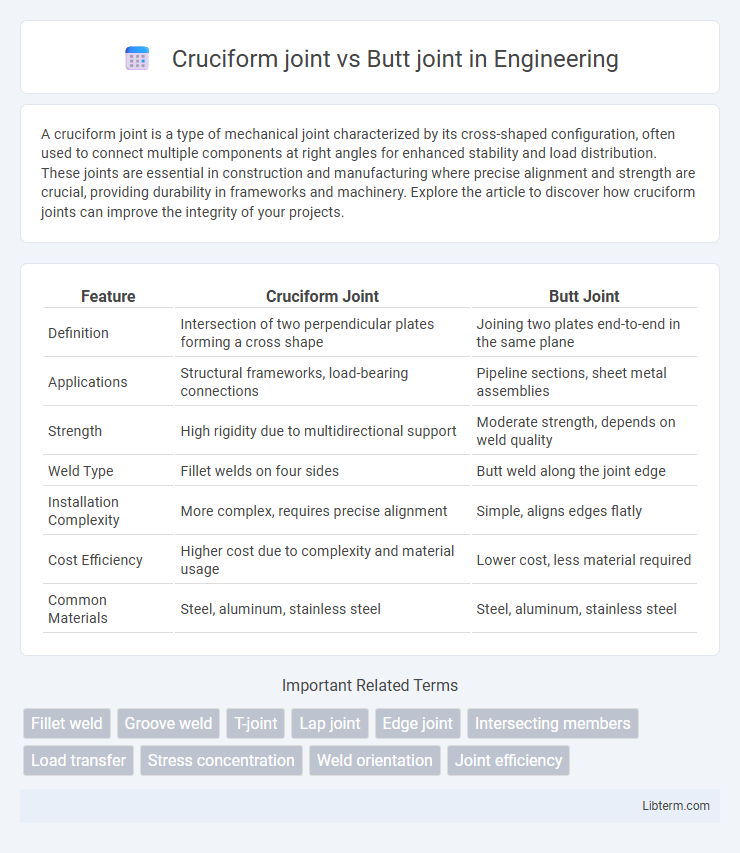

Table of Comparison

| Feature | Cruciform Joint | Butt Joint |

|---|---|---|

| Definition | Intersection of two perpendicular plates forming a cross shape | Joining two plates end-to-end in the same plane |

| Applications | Structural frameworks, load-bearing connections | Pipeline sections, sheet metal assemblies |

| Strength | High rigidity due to multidirectional support | Moderate strength, depends on weld quality |

| Weld Type | Fillet welds on four sides | Butt weld along the joint edge |

| Installation Complexity | More complex, requires precise alignment | Simple, aligns edges flatly |

| Cost Efficiency | Higher cost due to complexity and material usage | Lower cost, less material required |

| Common Materials | Steel, aluminum, stainless steel | Steel, aluminum, stainless steel |

Introduction to Cruciform and Butt Joints

Cruciform joints consist of four members intersecting at right angles, forming a cross-shaped connection widely used in structural frameworks for enhanced load distribution. Butt joints involve two components joined end-to-end in a single plane, commonly employed in welding and carpentry for straightforward assembly and alignment. Understanding these joint types is essential for selecting appropriate methods in construction, manufacturing, and material fabrication, optimizing strength and durability.

Definition of Cruciform Joint

A cruciform joint is a type of welded joint where three plates intersect at right angles, forming a cross-shaped configuration typically used in structural steel frameworks. Unlike a butt joint, where two plates are joined edge-to-edge in a single plane, the cruciform joint involves multiple members connected in different directions, providing enhanced stability and load distribution. This joint is essential in applications requiring multidirectional strength, such as bridge supports and building frames.

Definition of Butt Joint

A butt joint is a type of connection where two pieces of material are joined end-to-end or edge-to-edge without overlapping, typically used in woodworking, metalworking, and construction. This joint relies on welding, gluing, or mechanical fasteners to hold the pieces together in a single plane. In contrast, a cruciform joint involves four components intersecting at right angles, creating a cross-like shape often used for enhanced structural stability.

Structural Differences Between Cruciform and Butt Joints

Cruciform joints feature intersecting plates welded at right angles, creating a cross-shaped configuration that distributes stress more evenly and provides enhanced load-bearing capacity. Butt joints consist of two plates aligned edge-to-edge and welded along a single seam, resulting in a simpler, flat connection that may be less resistant to multi-directional forces. The inherent geometry of cruciform joints offers superior rigidity and structural integrity in applications involving complex stress patterns compared to the straightforward design of butt joints.

Common Applications of Cruciform Joints

Cruciform joints are widely used in structural steel frameworks, offering enhanced strength and load distribution at intersections where multiple beams meet perpendicularly. These joints are common in building frames, bridges, and heavy machinery, providing rigidity and resistance to bending forces. Cruciform joints are preferred over butt joints in applications requiring multidirectional load transfer and greater joint stability.

Common Applications of Butt Joints

Butt joints are widely used in structural steel frameworks, pipeline construction, and metal fabrication due to their straightforward alignment and ease of welding. They are common in automotive manufacturing for joining sheet metals and in shipbuilding where flat surfaces need to be joined edge-to-edge. This joint type provides a smooth finish ideal for applications requiring aesthetic continuity and structural integrity.

Strength and Load Capacity Comparison

Cruciform joints provide enhanced strength and load distribution due to their intersecting welds, making them ideal for structures subjected to multidirectional forces. Butt joints, with their linear weld path, offer reliable strength primarily in tensile or compressive loads but may be less effective under complex stress conditions. Load capacity in cruciform joints typically surpasses butt joints because of the combined weld areas which better resist shear and bending stresses.

Welding Techniques for Cruciform and Butt Joints

Welding techniques for cruciform joints typically involve multi-pass welding methods such as fillet welds applied at the intersection of three components, ensuring strong load distribution and minimizing stress concentrations. Butt joint welding primarily uses single or multiple pass groove welds, with techniques like TIG or MIG welding favored for their precision and penetration in joining two components end-to-end. Proper joint preparation, including edge beveling for butt joints and accurate alignment for cruciform joints, is essential to achieve optimal weld quality and mechanical performance.

Advantages and Disadvantages of Each Joint Type

The cruciform joint offers excellent strength and rigidity by intersecting three members perpendicularly, making it suitable for load-bearing structures, but it is prone to stress concentration and requires precise welding to avoid weak points. The butt joint is simpler to fabricate and inspect, with good alignment for joining two members end-to-end, offering cost efficiency and ease of access; however, it provides lower strength and rigidity compared to cruciform joints and may require additional reinforcement for heavy loads. Choosing between these joint types depends on the structural demands, welding skill availability, and load distribution requirements.

Choosing the Right Joint for Your Project

Choosing the right joint for your project depends on load requirements and aesthetic preferences. Cruciform joints offer high structural stability by interlocking materials at right angles, making them ideal for heavy-duty framing. Butt joints provide simpler, faster assembly with a clean finish, suitable for light to moderate load applications where speed and appearance are priorities.

Cruciform joint Infographic

libterm.com

libterm.com