Differential pressure measures the difference in pressure between two points in a system, crucial for monitoring fluid flow, filtration, and system performance. Accurate differential pressure readings help identify blockages, leaks, or inefficiencies in pipelines and HVAC systems. Discover how understanding differential pressure can optimize your system's efficiency by reading the rest of this article.

Table of Comparison

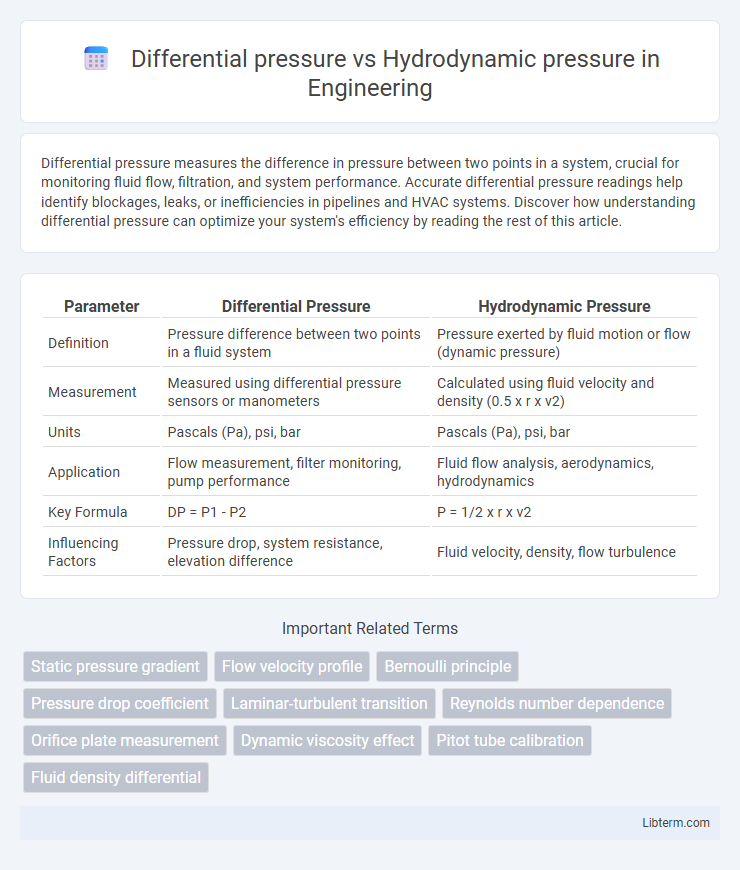

| Parameter | Differential Pressure | Hydrodynamic Pressure |

|---|---|---|

| Definition | Pressure difference between two points in a fluid system | Pressure exerted by fluid motion or flow (dynamic pressure) |

| Measurement | Measured using differential pressure sensors or manometers | Calculated using fluid velocity and density (0.5 x r x v2) |

| Units | Pascals (Pa), psi, bar | Pascals (Pa), psi, bar |

| Application | Flow measurement, filter monitoring, pump performance | Fluid flow analysis, aerodynamics, hydrodynamics |

| Key Formula | DP = P1 - P2 | P = 1/2 x r x v2 |

| Influencing Factors | Pressure drop, system resistance, elevation difference | Fluid velocity, density, flow turbulence |

Introduction to Differential Pressure and Hydrodynamic Pressure

Differential pressure measures the difference in pressure between two points in a system, often used to monitor fluid flow or filter performance. Hydrodynamic pressure refers to the pressure exerted by a fluid in motion, influenced by velocity and density according to Bernoulli's principle. Both pressures are critical in engineering applications such as fluid mechanics, HVAC systems, and hydraulic machinery for accurate system diagnostics and performance optimization.

Defining Differential Pressure: Principles and Applications

Differential pressure measures the difference in pressure between two points in a fluid system, essential for monitoring flow rates, filter blockages, and valve positions. It operates on the principle that pressure variation indicates changes in fluid dynamics, enabling precise control and safety in HVAC systems, process industries, and fluid mechanics. Applications include performance diagnostics in pumps, compressors, and filtration systems, where maintaining optimal pressure differences ensures efficiency and prevents equipment damage.

Understanding Hydrodynamic Pressure in Fluid Systems

Hydrodynamic pressure in fluid systems refers to the pressure exerted by a moving fluid, which depends on the fluid's velocity and density, described by Bernoulli's equation. Unlike differential pressure, which measures the pressure difference between two points to monitor flow or level changes, hydrodynamic pressure specifically captures the kinetic energy component of the fluid's motion. Accurately understanding hydrodynamic pressure is essential for designing efficient pumps, turbines, and fluid transport systems to optimize energy conversion and flow control.

Key Differences Between Differential and Hydrodynamic Pressure

Differential pressure measures the difference in pressure between two points within a system, crucial for monitoring flow rates, filter status, or pressure drops. Hydrodynamic pressure refers to the pressure exerted by a fluid in motion, directly related to fluid velocity and density, commonly described by Bernoulli's principle. The key difference lies in differential pressure quantifying pressure variation across components, while hydrodynamic pressure represents the fluid's dynamic impact due to flow conditions.

Measurement Techniques for Differential Pressure

Differential pressure measurement techniques primarily utilize devices such as differential pressure transducers, pitot tubes, and manometers to accurately gauge the pressure difference between two points in a fluid system. These instruments rely on pressure sensors or liquid columns to detect variations in static and dynamic pressures, enabling precise monitoring of flow rates, filter conditions, and level measurements. Unlike hydrodynamic pressure, which pertains to the total pressure within moving fluid influenced by velocity and elevation, differential pressure measurement focuses explicitly on the pressure disparity critical for system diagnostics and control.

Methods for Assessing Hydrodynamic Pressure

Hydrodynamic pressure is commonly assessed using computational fluid dynamics (CFD) simulations and experimental techniques such as particle image velocimetry (PIV) and pressure transducers embedded in fluid flow systems. Unlike differential pressure measurements, which typically involve sensors that detect pressure differences across a filter or restriction, hydrodynamic pressure evaluation emphasizes analyzing fluid velocity fields and pressure distributions around submerged objects. These methods provide precise insights into flow behavior, enabling optimized design and performance in hydraulic systems.

Application Areas: Differential vs Hydrodynamic Pressure

Differential pressure is crucial in applications like filtration monitoring, fluid flow measurement, and pump performance analysis, where the pressure difference between two points indicates operational efficiency or potential blockage. Hydrodynamic pressure plays a vital role in fluid dynamics studies, underwater vehicle design, and pipe flow systems, representing the pressure exerted by fluid motion on surfaces. Both pressures are essential in HVAC systems, industrial process control, and hydraulic machinery, with differential pressure guiding maintenance and hydrodynamic pressure influencing design optimization.

Advantages and Limitations of Each Pressure Type

Differential pressure offers precise measurement of pressure changes between two points, providing critical data for flow rate, filter condition, and system diagnostics, but it can be limited by sensor drift and installation complexity. Hydrodynamic pressure reflects the dynamic pressure exerted by fluid motion, enabling the analysis of fluid velocity and force, though its accuracy depends heavily on flow conditions and may be influenced by turbulence and cavitation. Choosing between differential and hydrodynamic pressure measurements depends on the specific application, with differential pressure favored for controlled environments and hydrodynamic pressure suited for open flow systems.

Common Challenges in Pressure Monitoring and Control

Differential pressure measurement often faces challenges such as sensor drift, cavity buildup, and accuracy loss in harsh environments, complicating reliable pressure control. Hydrodynamic pressure monitoring struggles with flow-induced fluctuations and turbulence effects, which can distort readings and impair system stability. Both pressure types require robust sensor calibration, signal filtering, and maintenance strategies to ensure accurate, real-time data for optimized process control.

Conclusion: Choosing the Right Pressure Measurement for Your Needs

Differential pressure accurately measures the difference between two points, making it ideal for flow monitoring and filter condition assessment. Hydrodynamic pressure refers to the pressure exerted by moving fluids and is crucial for applications involving fluid dynamics and pump performance. Selecting the right measurement depends on whether system diagnostics or fluid motion analysis is the primary requirement.

Differential pressure Infographic

libterm.com

libterm.com