Machining is a precise manufacturing process involving the removal of material to shape metal or plastic parts using tools like lathes, mills, and drills. It plays a critical role in producing high-quality components for industries such as automotive, aerospace, and medical devices. Discover how machining techniques can enhance your production efficiency and product quality by reading the rest of this article.

Table of Comparison

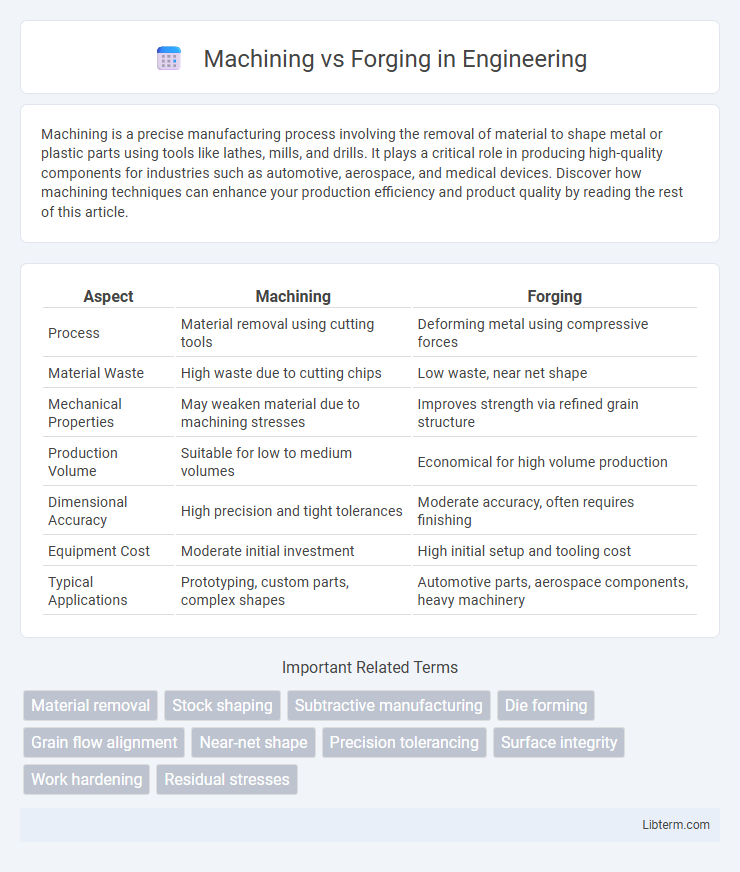

| Aspect | Machining | Forging |

|---|---|---|

| Process | Material removal using cutting tools | Deforming metal using compressive forces |

| Material Waste | High waste due to cutting chips | Low waste, near net shape |

| Mechanical Properties | May weaken material due to machining stresses | Improves strength via refined grain structure |

| Production Volume | Suitable for low to medium volumes | Economical for high volume production |

| Dimensional Accuracy | High precision and tight tolerances | Moderate accuracy, often requires finishing |

| Equipment Cost | Moderate initial investment | High initial setup and tooling cost |

| Typical Applications | Prototyping, custom parts, complex shapes | Automotive parts, aerospace components, heavy machinery |

Introduction to Machining and Forging

Machining involves removing material from a workpiece using tools like lathes, mills, or drills to achieve precise dimensions and surface finishes. Forging shapes metal through localized compressive forces, often using hammers or presses, resulting in enhanced strength and grain structure. Both processes serve distinct manufacturing needs, with machining offering accuracy and forging providing superior mechanical properties.

Overview of Machining Processes

Machining processes involve the removal of material from a workpiece through cutting, drilling, or grinding to achieve precise dimensions and surface finishes. Common machining techniques include turning, milling, drilling, and grinding, each employing specialized tools and machinery to shape metals or other materials. These processes offer high accuracy and repeatability, making them essential for producing complex parts in industries such as aerospace, automotive, and manufacturing.

Overview of Forging Processes

Forging processes involve shaping metal using compressive forces, typically performed hot or cold to enhance material strength and grain structure. Common types include open-die, closed-die, and impression-die forging, each offering distinct advantages in dimensional accuracy and mechanical properties. Forging improves fatigue resistance and structural integrity, making it ideal for high-stress components across automotive, aerospace, and industrial applications.

Key Differences Between Machining and Forging

Machining involves removing material from a workpiece using cutting tools to achieve precise dimensions and surface finishes, whereas forging shapes metal through localized compressive forces without removing material. Machining offers high accuracy and complex geometries but typically results in slower production and higher material waste, while forging provides superior mechanical properties due to grain refinement and is ideal for high-strength components with less material loss. The selection between machining and forging depends on factors such as part complexity, strength requirements, production volume, and cost efficiency.

Material Suitability: Machining vs. Forging

Machining is ideal for materials like aluminum, brass, and mild steel that offer ease of cutting and fine surface finishes, while forging suits high-strength alloys such as titanium, stainless steel, and carbon steels that benefit from enhanced grain structure and increased mechanical properties. Forging improves metal properties through plastic deformation, making it suitable for components requiring superior toughness and fatigue resistance. Machining offers flexibility for complex geometries and tighter tolerances but may result in weaker material properties compared to forged parts.

Strength and Durability Comparison

Forged components exhibit superior strength and durability compared to machined parts due to their grain flow alignment, which enhances resistance to fatigue and impact. Machining removes material from a solid block, potentially weakening the part's structural integrity, while forging compresses and shapes metal to improve internal consistency and toughness. As a result, forged parts are preferred in high-stress applications such as aerospace and automotive industries where maximum strength and long-term durability are critical.

Cost Considerations in Machining and Forging

Machining involves higher material waste and longer processing times, leading to increased operational costs compared to forging. Forging offers cost efficiency through material savings and faster production rates due to near-net shaping and minimal machining requirements. Tooling expenses in forging are initially higher but are offset by lower per-part costs in high-volume manufacturing runs.

Precision and Tolerances: Which is Better?

Machining offers superior precision and tighter tolerances compared to forging due to its controlled material removal process, enabling intricate and complex geometries with micrometer-level accuracy. Forging, while excellent for enhancing material strength and grain structure, generally achieves less precise dimensions and requires secondary machining for critical tolerances. For applications demanding exact fits and high precision, machining is the preferred method, whereas forging is advantageous for robust, high-strength components with moderate dimensional requirements.

Typical Applications for Machined and Forged Parts

Machined parts are commonly utilized in aerospace components, automotive precision gears, and custom medical implants due to their tight tolerances and complex geometries. Forged parts find typical applications in high-strength automotive crankshafts, heavy-duty industrial shafts, and structural components in construction equipment, offering enhanced mechanical properties and durability. Both manufacturing methods serve critical roles in industries requiring reliability and performance under stress.

Choosing the Right Process for Your Project

Machining offers high precision and is ideal for intricate parts with tight tolerances, while forging produces components with superior strength and durability due to grain flow alignment. Selecting the right process depends on factors such as material properties, production volume, and cost constraints, where forging suits large batches requiring enhanced mechanical properties and machining fits custom or low-volume projects needing detailed specifications. Evaluating these criteria ensures optimized performance and cost-efficiency in your manufacturing project.

Machining Infographic

libterm.com

libterm.com