Busbars efficiently conduct and distribute electrical power within switchboards, substations, and control panels, minimizing energy loss and enhancing system reliability. Their design supports high current loads while maintaining safety and reducing maintenance needs, making them essential for modern electrical infrastructure. Explore the article to discover how busbars optimize your electrical systems and improve overall performance.

Table of Comparison

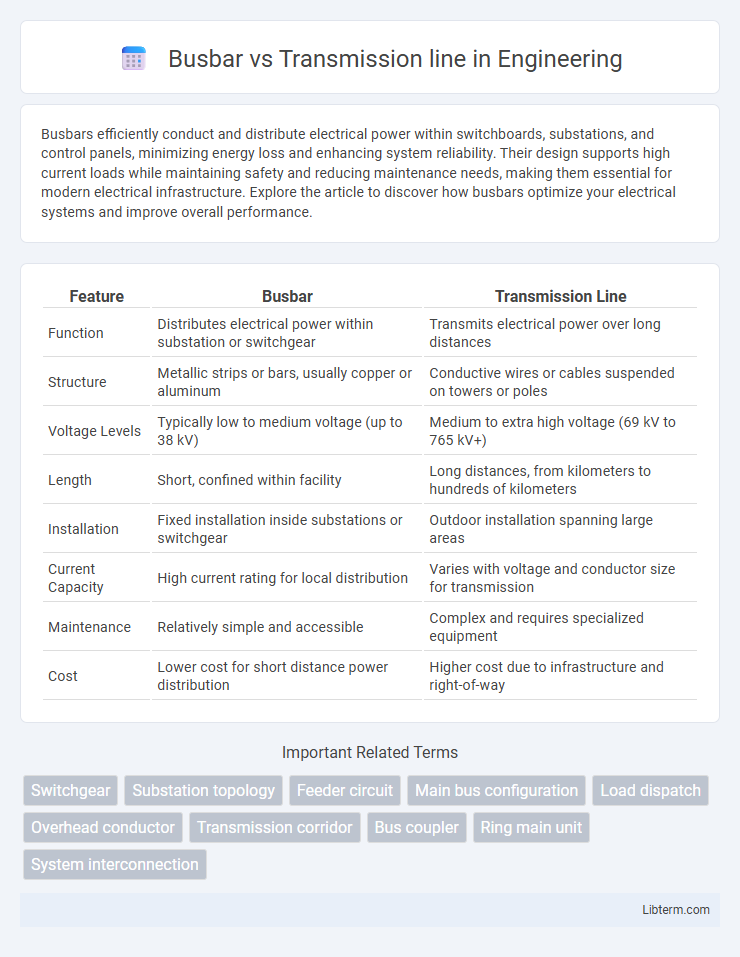

| Feature | Busbar | Transmission Line |

|---|---|---|

| Function | Distributes electrical power within substation or switchgear | Transmits electrical power over long distances |

| Structure | Metallic strips or bars, usually copper or aluminum | Conductive wires or cables suspended on towers or poles |

| Voltage Levels | Typically low to medium voltage (up to 38 kV) | Medium to extra high voltage (69 kV to 765 kV+) |

| Length | Short, confined within facility | Long distances, from kilometers to hundreds of kilometers |

| Installation | Fixed installation inside substations or switchgear | Outdoor installation spanning large areas |

| Current Capacity | High current rating for local distribution | Varies with voltage and conductor size for transmission |

| Maintenance | Relatively simple and accessible | Complex and requires specialized equipment |

| Cost | Lower cost for short distance power distribution | Higher cost due to infrastructure and right-of-way |

Introduction to Busbars and Transmission Lines

Busbars are rigid, conductive strips or bars used in electrical power distribution systems to collect and distribute electric current efficiently within switchgear, panel boards, and busway enclosures. Transmission lines consist of conductors, usually overhead or underground cables, designed to transmit high-voltage electrical power over long distances between generating stations and substations. Busbars provide low-impedance pathways crucial for internal circuit connections, whereas transmission lines focus on minimizing power losses and maintaining voltage stability across extended geographical areas.

Fundamental Differences Between Busbars and Transmission Lines

Busbars are rigid metallic strips or bars that distribute electrical power within switchgear, panel boards, and substations, whereas transmission lines are conductors that transport electricity over long distances between generating stations and substations. The fundamental difference lies in their function and design; busbars provide centralized power distribution with low impedance and minimal voltage drop, while transmission lines handle high-voltage power transfer with consideration for line impedance, insulation, and environmental factors. Busbars operate primarily indoors and require compact, secure connections, whereas transmission lines are typically exposed outdoors and engineered to withstand weather conditions and mechanical stress.

Construction and Design Aspects

Busbars feature compact, rigid metal bars, typically copper or aluminum, designed for low resistance and efficient current distribution within switchgear or substations. Transmission lines consist of overhead or underground conductors supported by towers or poles, engineered for long-distance electrical power transfer with insulation and environmental protection considerations. Design priorities for busbars emphasize short, durable connections with minimal inductance, while transmission lines focus on mechanical strength, electrical clearance, and minimizing energy loss over vast distances.

Electrical Functionality and Applications

Busbars serve as centralized electrical conductors designed to distribute power efficiently within switchgear, substations, and distribution panels, offering low impedance and compact design for high-current applications. Transmission lines, engineered for long-distance power delivery, maintain voltage and minimize losses over vast distances using overhead cables or underground conductors, essential for grid interconnections. Busbars are ideal for localized power distribution and short electrical paths, while transmission lines enable large-scale energy transfer across regions in power systems.

Material Choices and Conductivity Considerations

Busbars typically use copper or aluminum due to their excellent electrical conductivity and thermal performance crucial for short, high-current connections in switchgear and panel boards. Transmission lines often employ aluminum conductors with a steel core (ACSR) to balance conductivity, tensile strength, and weight over long distances. Material selection hinges on the trade-off between conductivity, mechanical strength, and cost, with copper preferred for busbars and aluminum-based conductors dominating transmission lines.

Power Transmission Capacity Comparison

Busbars typically have a lower power transmission capacity compared to transmission lines, being more suitable for short-distance electrical distribution within substations or switchgear panels. Transmission lines are designed to carry high voltage power over long distances, with capacities ranging from hundreds of megawatts to several gigawatts depending on conductor size, voltage level, and configuration. While busbars offer flexibility and compactness for routing current in confined spaces, transmission lines provide higher capacity and efficiency essential for bulk power transfer across regions.

Installation Environments and Physical Layouts

Busbars are typically installed indoors within electrical panels or switchgear rooms, offering compact, rigid physical layouts that facilitate easy connection and maintenance. Transmission lines are deployed outdoors over long distances, requiring tall towers or poles that maintain physical clearance and accommodate weather conditions. The installation environment of busbars emphasizes controlled, confined spaces, while transmission lines demand expansive, open terrains designed for efficient high-voltage power transmission.

Losses and Efficiency Analysis

Busbars exhibit lower resistive losses compared to transmission lines due to their short length and larger cross-sectional area, enhancing overall system efficiency. Transmission lines, especially over long distances, experience higher I2R losses and suffer from dielectric and corona effects, reducing their efficiency significantly. Analyzing these losses using parameters like resistance, reactance, and environmental factors is crucial for optimizing power distribution and minimizing energy dissipation.

Safety, Maintenance, and Reliability Factors

Busbars offer enhanced safety due to their enclosed and rigid structure, reducing the risk of electrical faults and accidental contact compared to transmission lines. Maintenance on busbars is generally easier and less frequent, facilitated by their accessible design and fewer exposed components, whereas transmission lines require regular inspections and repairs due to environmental exposure. Reliability factors favor busbars in controlled environments because of lower susceptibility to weather conditions and physical damage, while transmission lines are more prone to outages caused by storms, corrosion, and external impacts.

Selection Criteria: When to Use Busbars vs Transmission Lines

Busbars are ideal for short-distance power distribution within substations or switchgear due to their compact design and high current-carrying capacity. Transmission lines are preferred for long-distance electrical power transfer, offering efficiency over extended ranges and the ability to connect different grid sections. Selection depends on factors such as distance, current load, installation environment, and cost-effectiveness for the specific electrical network configuration.

Busbar Infographic

libterm.com

libterm.com