Surface finish significantly influences the performance and aesthetics of manufactured parts by affecting friction, wear resistance, and paint adhesion. Achieving the optimal surface finish depends on factors such as material type, machining processes, and desired functional properties. Explore the rest of the article to discover how to select and improve surface finishes for your specific applications.

Table of Comparison

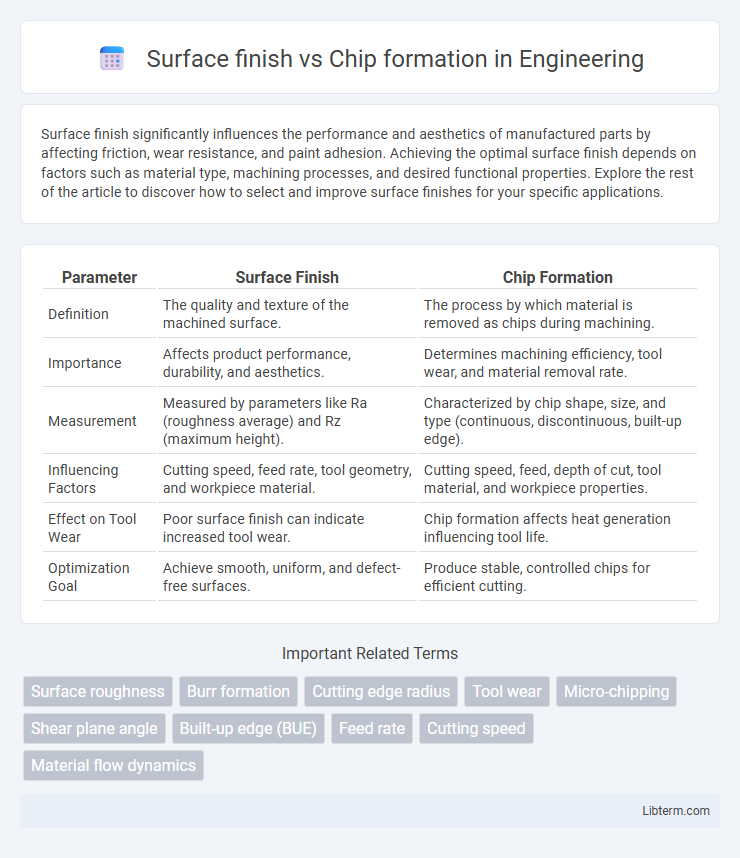

| Parameter | Surface Finish | Chip Formation |

|---|---|---|

| Definition | The quality and texture of the machined surface. | The process by which material is removed as chips during machining. |

| Importance | Affects product performance, durability, and aesthetics. | Determines machining efficiency, tool wear, and material removal rate. |

| Measurement | Measured by parameters like Ra (roughness average) and Rz (maximum height). | Characterized by chip shape, size, and type (continuous, discontinuous, built-up edge). |

| Influencing Factors | Cutting speed, feed rate, tool geometry, and workpiece material. | Cutting speed, feed, depth of cut, tool material, and workpiece properties. |

| Effect on Tool Wear | Poor surface finish can indicate increased tool wear. | Chip formation affects heat generation influencing tool life. |

| Optimization Goal | Achieve smooth, uniform, and defect-free surfaces. | Produce stable, controlled chips for efficient cutting. |

Introduction to Surface Finish and Chip Formation

Surface finish refers to the texture and quality of a machined surface, significantly influenced by cutting conditions and tool geometry. Chip formation is the process where material is removed from a workpiece in the form of chips during cutting, directly impacting surface integrity and machining efficiency. Understanding the relationship between these two phenomena is critical for optimizing manufacturing processes and achieving desired product specifications.

Importance of Surface Finish in Machining

Surface finish directly influences the performance and lifespan of machined components by reducing friction, wear, and fatigue. Achieving an optimal surface finish improves dimensional accuracy and enhances the adhesion of coatings or paints, critical in industries such as aerospace and automotive manufacturing. Surface roughness parameters like Ra and Rz are essential metrics for evaluating chip formation effects and ensuring machining processes produce high-quality, functional parts.

Fundamentals of Chip Formation Mechanisms

Surface finish quality is directly influenced by chip formation mechanisms during machining processes, where continuous, segmented, or discontinuous chips result in varying surface textures. Fundamental factors affecting chip formation include material properties, cutting speed, feed rate, and tool geometry, which determine shear plane behavior and chip morphology. Optimizing these parameters minimizes built-up edge and tool wear, improving surface finish by controlling the plastic deformation and fracture behavior in the primary deformation zone.

Influence of Cutting Parameters on Surface Quality

Cutting parameters such as cutting speed, feed rate, and depth of cut critically influence both surface finish and chip formation in machining processes. Higher cutting speeds often improve surface quality by reducing built-up edge formation but can lead to increased tool wear affecting chip morphology. Optimal feed rates and depths of cut minimize surface roughness and promote favorable chip characteristics by controlling heat generation and material deformation during cutting.

Relationship Between Chip Type and Surface Roughness

The type of chip formed during metal cutting directly influences surface roughness, with continuous chips typically producing smoother finishes due to stable cutting action. Segmented or discontinuous chips often result in higher surface roughness because of irregular tool engagement and increased vibration. Optimizing cutting parameters to promote favorable chip formation improves surface integrity and machining efficiency.

Tool Geometry Impact on Chip and Surface Topography

Tool geometry significantly influences chip formation by dictating chip flow direction, thickness, and segmentation, which directly affects surface topography quality. Specific angles such as rake, clearance, and cutting edge radius alter stress distribution and heat generation, leading to variations in chip morphology and surface finish. Optimized tool geometry minimizes built-up edge and workpiece deformation, enhancing surface smoothness and dimensional accuracy in machining processes.

Material Properties Affecting Chip Formation and Finish

Material properties such as hardness, ductility, and thermal conductivity significantly influence chip formation and surface finish during machining. Harder materials tend to produce continuous chips and smoother finishes, while ductile materials often generate segmented or built-up edge chips that degrade surface quality. Thermal conductivity affects heat dissipation, impacting tool wear and the resulting surface integrity, making it a critical factor in achieving optimal surface finish.

Lubrication and Cooling: Effects on Chip and Surface

Effective lubrication and cooling during machining critically influence chip formation and surface finish quality. Proper cooling minimizes thermal deformation and reduces built-up edge on the cutting tool, resulting in smoother chip flow and improved surface integrity. Lubricants decrease friction between the tool and workpiece, leading to finer surface textures and controlled chip morphology, enhancing overall machining efficiency.

Common Surface Defects Linked to Chip Formation

Common surface defects linked to chip formation include built-up edge (BUE), built-up layer (BUL), and shear striations, which can deteriorate surface finish quality. BUE causes irregularities by adhering to the cutting tool, while BUL results from the accumulation of material on the workpiece surface, both leading to roughness and dimensional inaccuracies. Proper control of cutting parameters such as feed rate, cutting speed, and tool geometry is essential to minimize these defects and improve the overall surface finish in machining processes.

Strategies to Optimize Both Chip Formation and Surface Finish

Optimizing chip formation and surface finish involves selecting proper cutting parameters such as feed rate, cutting speed, and tool geometry to balance efficient material removal with minimal surface roughness. Utilizing coated or wear-resistant tools helps maintain sharpness, reducing built-up edge and improving surface integrity. Implementing high-pressure coolant or employing vibration-damping techniques further enhances chip control and surface quality during machining processes.

Surface finish Infographic

libterm.com

libterm.com