Arc welding uses an electric arc to melt and join metals, creating strong, durable bonds ideal for structural and manufacturing applications. This process offers versatility across materials like steel, aluminum, and stainless steel, making it essential for construction and repair tasks. Discover how mastering arc welding techniques can enhance Your projects by exploring the full article.

Table of Comparison

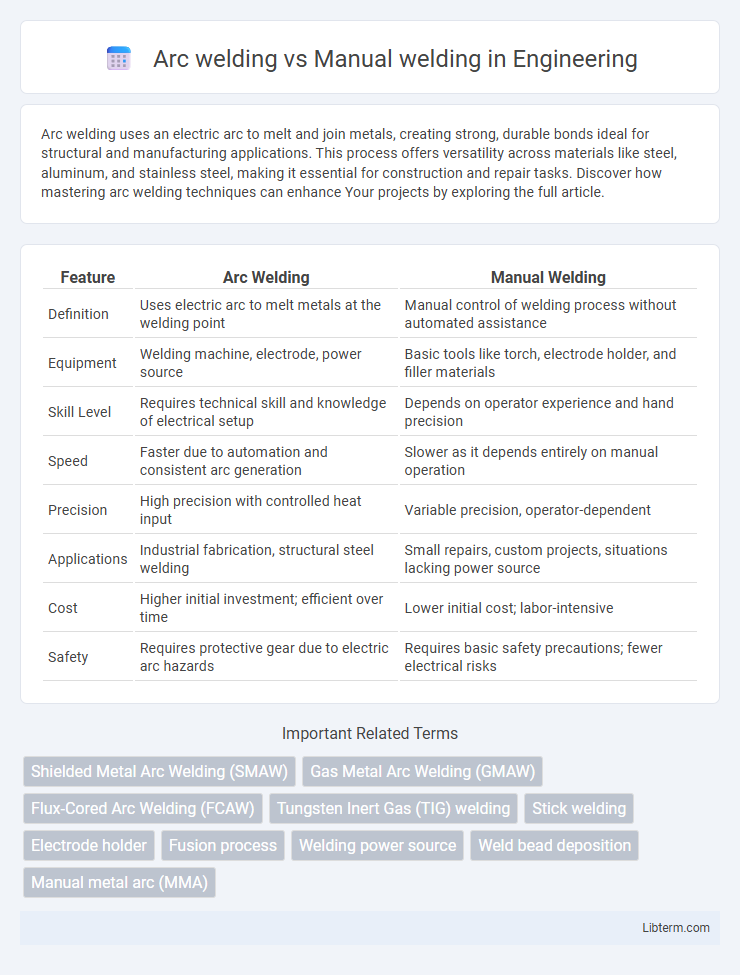

| Feature | Arc Welding | Manual Welding |

|---|---|---|

| Definition | Uses electric arc to melt metals at the welding point | Manual control of welding process without automated assistance |

| Equipment | Welding machine, electrode, power source | Basic tools like torch, electrode holder, and filler materials |

| Skill Level | Requires technical skill and knowledge of electrical setup | Depends on operator experience and hand precision |

| Speed | Faster due to automation and consistent arc generation | Slower as it depends entirely on manual operation |

| Precision | High precision with controlled heat input | Variable precision, operator-dependent |

| Applications | Industrial fabrication, structural steel welding | Small repairs, custom projects, situations lacking power source |

| Cost | Higher initial investment; efficient over time | Lower initial cost; labor-intensive |

| Safety | Requires protective gear due to electric arc hazards | Requires basic safety precautions; fewer electrical risks |

Overview of Arc Welding and Manual Welding

Arc welding utilizes an electric arc to generate intense heat that melts the base metals and filler material, enabling strong, precise joints suited for industrial applications. Manual welding, often referred to as shielded metal arc welding (SMAW), relies on skilled operators to control the welding process with handheld electrodes, offering versatility for outdoor and repair work. Both methods require specific equipment and training but differ significantly in automation, efficiency, and typical usage scenarios.

Key Differences Between Arc and Manual Welding

Arc welding uses an electric arc to generate intense heat, melting metals precisely and enabling strong, uniform welds, while manual welding relies on hand-held tools without electric arcs. Arc welding offers higher efficiency, better penetration, and suitability for thick materials, whereas manual welding, often involving simpler techniques like oxy-fuel, is more versatile for on-site repairs and thinner metals. Key differences include power source dependency, control precision, skill level requirements, and application scope, with arc welding favored in industrial environments and manual welding preferred for portability and ease.

Equipment Used in Arc vs Manual Welding

Arc welding utilizes electric power sources, such as transformers, generators, or inverters, to generate the necessary electric arc, along with consumable or non-consumable electrodes depending on the process type. Manual welding primarily relies on handheld tools like oxy-acetylene torches and filler rods, requiring skilled operator control and fewer electrical components. The equipment complexity and energy requirements in arc welding are generally higher, offering greater precision and efficiency compared to the more straightforward, labor-intensive tools used in manual welding.

Applications and Suitability

Arc welding is ideal for heavy-duty construction, shipbuilding, and industrial fabrication due to its strong, durable welds on thick metals like steel and iron. Manual welding, commonly known as stick welding, suits maintenance repairs, fieldwork, and outdoor projects because it allows greater control and versatility on varied materials and positions. Arc welding offers higher efficiency and productivity in large-scale manufacturing, while manual welding excels in precise, small-scale, or on-site applications.

Skill Requirements for Each Welding Method

Arc welding typically requires formal training and certification due to its reliance on precise electrical control and the use of specialized equipment, demanding a strong understanding of electrical safety and welding techniques. Manual welding, such as stick welding, requires skilled hand-eye coordination and experience to maintain consistent electrode angles and arc length, often developed through hands-on practice rather than formal education. Mastery in arc welding generally involves understanding complex equipment settings, while manual welding emphasizes steady physical control and adaptability in various working conditions.

Safety Considerations in Arc and Manual Welding

Arc welding poses significant safety risks due to intense ultraviolet radiation, hot sparks, and hazardous fumes, requiring protective gear like welding helmets with auto-darkening filters and flame-resistant clothing. Manual welding also demands stringent safety measures, including eye protection, gloves, and ventilation, though it often involves lower exposure to electrical hazards compared to arc welding. Proper training and adherence to safety protocols reduce the risk of burns, electric shock, and respiratory issues in both welding methods.

Cost Comparison of Arc and Manual Welding

Arc welding generally offers lower labor costs due to its higher speed and automation potential, reducing overall production time. Manual welding, while providing greater control and precision for intricate tasks, typically incurs higher labor expenses and slower project completion. Equipment costs for arc welding can be higher initially, but these are offset by improved efficiency and reduced rework compared to manual welding methods.

Quality and Strength of Welds

Arc welding produces high-quality welds with deep penetration and strong fusion, making it ideal for thick metals and critical structural applications. Manual welding depends heavily on the welder's skill, resulting in variable weld strength and consistency, which may lead to weak or flawed joints. Arc welding's precise control over heat and welding parameters generally ensures superior weld strength compared to manual techniques.

Efficiency and Speed of the Welding Processes

Arc welding offers higher efficiency and faster welding speeds compared to manual welding due to its automated control and consistent electric arc generation, which reduces human error and downtime. Manual welding requires skilled operators and is generally slower because of the reliance on hand movements and adjustments for each weld, leading to variability in speed and quality. In industrial applications, arc welding improves productivity by providing continuous, uniform welds that minimize rework and increase throughput.

Choosing the Right Welding Technique for Your Project

Arc welding offers higher precision and efficiency for metal fabrication, making it ideal for complex or large-scale projects requiring strong, durable joints. Manual welding provides greater flexibility and control for smaller, detailed tasks or repairs, especially when working in tight spaces or on uneven surfaces. Selecting the right welding technique depends on project size, material type, skill level, and desired weld quality to ensure optimal results.

Arc welding Infographic

libterm.com

libterm.com