Bolting is a critical process in mechanical assembly that ensures secure fastening of components using threaded fasteners such as bolts and nuts. Proper bolting techniques enhance structural integrity, prevent machinery failures, and optimize load distribution under various operating conditions. Explore this article to discover essential bolting methods and best practices that can improve your project's reliability and safety.

Table of Comparison

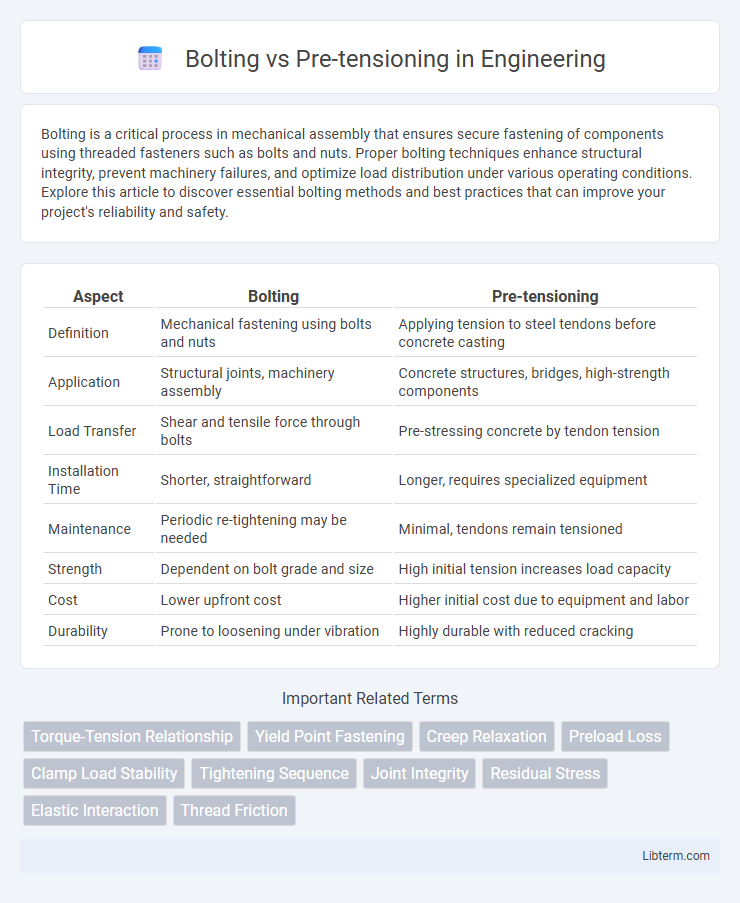

| Aspect | Bolting | Pre-tensioning |

|---|---|---|

| Definition | Mechanical fastening using bolts and nuts | Applying tension to steel tendons before concrete casting |

| Application | Structural joints, machinery assembly | Concrete structures, bridges, high-strength components |

| Load Transfer | Shear and tensile force through bolts | Pre-stressing concrete by tendon tension |

| Installation Time | Shorter, straightforward | Longer, requires specialized equipment |

| Maintenance | Periodic re-tightening may be needed | Minimal, tendons remain tensioned |

| Strength | Dependent on bolt grade and size | High initial tension increases load capacity |

| Cost | Lower upfront cost | Higher initial cost due to equipment and labor |

| Durability | Prone to loosening under vibration | Highly durable with reduced cracking |

Introduction to Bolting vs Pre-tensioning

Bolting and pre-tensioning are critical techniques in structural engineering used to join components securely. Bolting relies on mechanical fasteners tightened to create clamping force, while pre-tensioning involves applying a predetermined tension to bolts before assembly to enhance joint strength and fatigue resistance. Understanding the differences between bolting and pre-tensioning ensures optimal joint performance in various construction and mechanical applications.

Definitions: What is Bolting?

Bolting is a mechanical fastening method that involves joining two or more components using threaded fasteners called bolts, which are tightened to create a clamping force. This technique relies on friction between the bolt, nut, and the connected surfaces to maintain structural integrity. Bolting is widely used in construction, machinery, and automotive industries for its ease of assembly and disassembly.

Understanding Pre-tensioning in Construction

Pre-tensioning in construction involves stressing steel tendons before casting concrete, which significantly enhances structural strength and durability by inducing compressive forces that counteract tensile stresses. This method improves load distribution and reduces the risk of cracks, ideal for bridges, slabs, and beams exposed to heavy loads. Unlike bolting, which relies on mechanical fasteners to join components, pre-tensioning integrates reinforcement within the concrete matrix, resulting in a more cohesive and resilient structure.

Key Differences Between Bolting and Pre-tensioning

Bolting involves fastening components using threaded fasteners that rely on friction between the bolt and nut to resist loads, while pre-tensioning applies a controlled initial tension to steel tendons or cables before load application, enhancing structural performance through load distribution. Bolting is typically used for assemblies requiring disassembly or adjustment, whereas pre-tensioning is common in concrete structures to improve crack resistance and durability. The key difference lies in load transfer: bolting depends on shear resistance at the joint interface, whereas pre-tensioning induces compressive forces that counteract tensile stresses within the material.

Materials and Tools Used in Each Method

Bolting relies on high-strength steel bolts, nuts, and washers, requiring torque wrenches and impact drivers to ensure proper tightening and load distribution. Pre-tensioning utilizes specialized high-tensile steel strands or cables, tensioned with hydraulic jacks and anchored using wedge anchors or mechanical grips for controlled stress application. The choice of materials and tools directly influences the structural performance and durability of connections in construction and manufacturing projects.

Applications in Structural Engineering

Bolting is commonly applied in structural engineering for assembling steel frameworks, bridges, and heavy machinery due to its ease of installation and maintenance. Pre-tensioning is primarily used in concrete structures, such as pre-stressed concrete beams and slabs, to improve load-bearing capacity and reduce cracking by applying tensile forces before external loads are applied. The choice between bolting and pre-tensioning depends on factors like structural requirements, load conditions, fatigue resistance, and the need for long-term durability.

Advantages of Bolting

Bolting offers easy installation and disassembly, making it ideal for structures requiring frequent maintenance or adjustments. It provides strong mechanical fastening without the need for specialized equipment, reducing labor costs and time on site. Additionally, bolted connections are versatile, accommodating various bolt sizes and materials to suit different load requirements and environmental conditions.

Benefits of Pre-tensioning

Pre-tensioning enhances joint reliability by applying tension to bolts before load application, reducing joint slip and increasing structural integrity. This method distributes stress evenly across connected components, minimizing fatigue and extending service life in critical engineering applications. It also improves vibration resistance, making pre-tensioned assemblies ideal for dynamic and high-load environments.

Challenges and Limitations

Bolting faces challenges such as potential loosening under vibration and uneven load distribution, leading to joint fatigue and decreased structural integrity. Pre-tensioning limitations include the need for specialized equipment and higher initial costs, which can restrict its application in certain projects. Both methods require precise installation to avoid failure, with bolting demanding torque control and pre-tensioning relying on accurate tension levels.

Choosing the Right Method for Your Project

Choosing between bolting and pre-tensioning depends on the structural requirements and load conditions of your project. Bolting offers flexibility and ease of installation for applications needing frequent disassembly or moderate load resistance, while pre-tensioning provides superior clamping force and fatigue resistance, ideal for high-stress environments and permanent joints. Assess factors such as load type, assembly time, maintenance, and cost to determine the optimal fastening method for long-term performance.

Bolting Infographic

libterm.com

libterm.com