Brinell hardness measures the resistance of materials to indentation by pressing a hardened steel or carbide ball into the surface under a specified load. This test provides valuable data for assessing materials used in engineering and manufacturing, especially metals with coarse structures or non-uniform hardness. Explore the full article to understand how Brinell hardness testing can impact your material selection and quality control processes.

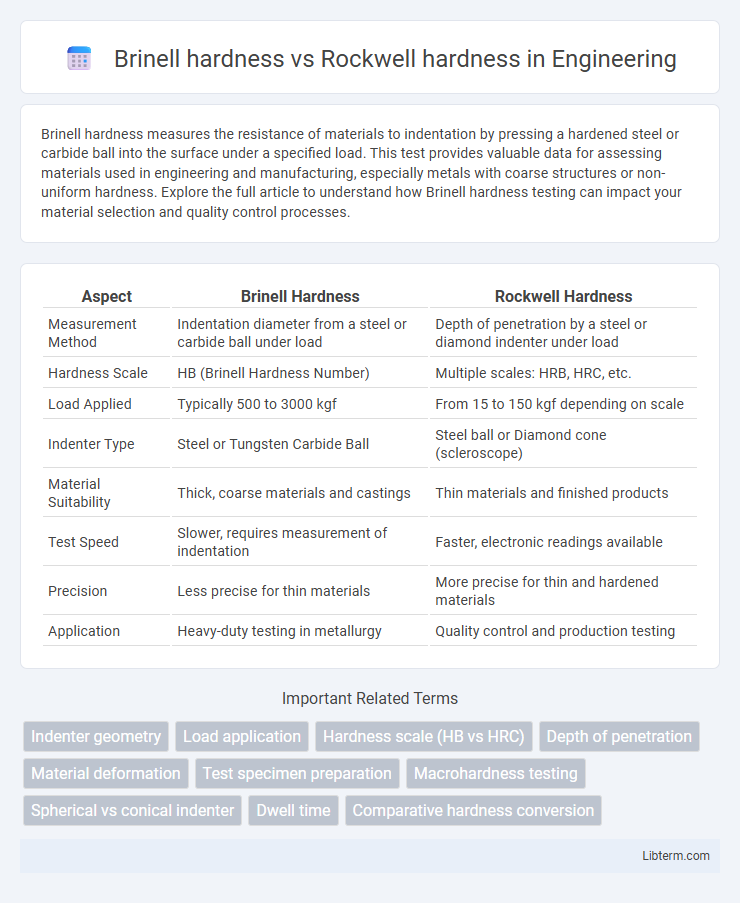

Table of Comparison

| Aspect | Brinell Hardness | Rockwell Hardness |

|---|---|---|

| Measurement Method | Indentation diameter from a steel or carbide ball under load | Depth of penetration by a steel or diamond indenter under load |

| Hardness Scale | HB (Brinell Hardness Number) | Multiple scales: HRB, HRC, etc. |

| Load Applied | Typically 500 to 3000 kgf | From 15 to 150 kgf depending on scale |

| Indenter Type | Steel or Tungsten Carbide Ball | Steel ball or Diamond cone (scleroscope) |

| Material Suitability | Thick, coarse materials and castings | Thin materials and finished products |

| Test Speed | Slower, requires measurement of indentation | Faster, electronic readings available |

| Precision | Less precise for thin materials | More precise for thin and hardened materials |

| Application | Heavy-duty testing in metallurgy | Quality control and production testing |

Introduction to Hardness Testing

Hardness testing measures a material's resistance to deformation, with Brinell and Rockwell tests being two primary methods used in industry. The Brinell hardness test employs a steel or carbide ball indenter and is ideal for materials with rough surfaces or heterogeneous structures, providing an average hardness value over a larger area. The Rockwell hardness test uses a steel ball or diamond cone indenter and offers rapid results with minimal specimen preparation, making it suitable for quality control and comparison of different metals.

Overview of Brinell Hardness Test

The Brinell Hardness Test measures the resistance of materials to indentation using a hardened steel or carbide ball under a fixed load, providing an average hardness value over a larger surface area. This test is ideal for materials with coarse structures or uneven surfaces, as it minimizes localized variations in hardness. Brinell hardness numbers (BHN) are calculated by dividing the applied load by the surface area of the indentation, offering a reliable metric for comparing material strength and wear resistance.

Overview of Rockwell Hardness Test

The Rockwell hardness test measures the depth of penetration under a fixed load using a steel ball or diamond cone indenter, providing rapid and direct hardness values on a dial. It is widely used for metals and alloys due to its convenience, requiring minimal specimen preparation and offering multiple scales for various materials. Compared to the Brinell hardness test, which calculates hardness by the size of an indentation, the Rockwell method delivers faster results and is better suited for thinner or harder materials.

Testing Principles: Brinell vs. Rockwell

Brinell hardness testing measures material resistance by pressing a hardened steel or carbide ball into the surface under a specified load and calculating hardness based on the indentation diameter. Rockwell hardness testing uses a steel or carbide indenter that penetrates the material under a minor and then a major load, directly measuring the depth of penetration to determine hardness. The Brinell method is ideal for testing coarse-grained materials and rough surfaces, while Rockwell provides faster results and is suitable for a wide range of materials, including thin sections.

Indenters and Loads Comparison

Brinell hardness testing uses a large steel or carbide ball indenter typically ranging from 1 mm to 10 mm in diameter and applies loads from 500 to 3000 kgf, making it suitable for testing coarse materials and surfaces. Rockwell hardness testing utilizes smaller indenters such as a 1/16 inch steel ball or a diamond cone (brale) with loads varying from 15 to 150 kgf, enabling rapid and direct hardness readings on thinner or harder materials. The difference in indenter size and applied load directly influences measurement depth and surface area tested, impacting the suitability of Brinell for rough, uneven surfaces versus Rockwell for finished components.

Application Areas for Each Method

Brinell hardness testing is widely used for measuring the hardness of materials with coarse structures, such as castings and forgings, making it ideal for metals like cast iron and aluminum alloys. Rockwell hardness testing is preferred in quality control for finished products and thin materials, including hardened steels, plastics, and thin metal sheets, due to its faster and non-destructive nature. Industries such as automotive, aerospace, and manufacturing rely on Rockwell for rapid testing, while heavy machinery and foundry sectors commonly use the Brinell method for durability assessments.

Advantages and Limitations

Brinell hardness testing offers the advantage of measuring material hardness on a larger surface area, making it ideal for heterogeneous or coarse-grained materials, but it has limitations with small or thin samples due to the large indentation size. Rockwell hardness testing provides rapid and direct readings with minimal sample preparation, making it suitable for production environments, yet it may produce less accurate results on very soft or very hard materials. Both methods are essential in material science, with Brinell favored for wear-resistant metals and Rockwell for quality control in manufacturing.

Accuracy and Repeatability

Brinell hardness testing provides high accuracy for materials with coarse or uneven surfaces due to its large indenter size, promoting consistent penetration and reducing variability. Rockwell hardness testing offers greater repeatability because of its automated depth measurement and faster testing cycles, minimizing operator influence and enhancing precision on smoother materials. Both methods have distinct advantages: Brinell excels in accuracy for rough surfaces, while Rockwell ensures superior repeatability in controlled testing environments.

Interpreting Hardness Results

Interpreting Brinell hardness results involves analyzing the diameter of the indentation made by a steel or carbide ball under a specified load, with larger indentations indicating softer materials and smaller indentations indicating harder materials. Rockwell hardness measures the depth of penetration under a fixed load using different scales (such as HRB or HRC), offering quicker and more direct readings compared to Brinell. Both methods require understanding material-specific scales and conversion charts to accurately compare hardness values across diverse metals and alloys.

Selecting the Right Hardness Test

Selecting the right hardness test depends on the material type, thickness, and surface condition, with Brinell hardness testing ideal for coarse, uneven surfaces and larger, softer metals due to its use of a steel or carbide ball indenter. Rockwell hardness testing suits thinner, harder materials and offers multiple scales (e.g., A, B, C) based on the indenter type and load, providing rapid and non-destructive testing. Understanding material properties and application requirements ensures accurate hardness measurement, optimizing durability and performance assessments.

Brinell hardness Infographic

libterm.com

libterm.com