Varying load conditions significantly impact the performance and efficiency of mechanical systems and electrical devices. Understanding how changes in load affect energy consumption, wear and tear, and system stability is crucial for optimizing operation and extending lifespan. Explore the rest of this article to learn how managing varying load can enhance your system's reliability and efficiency.

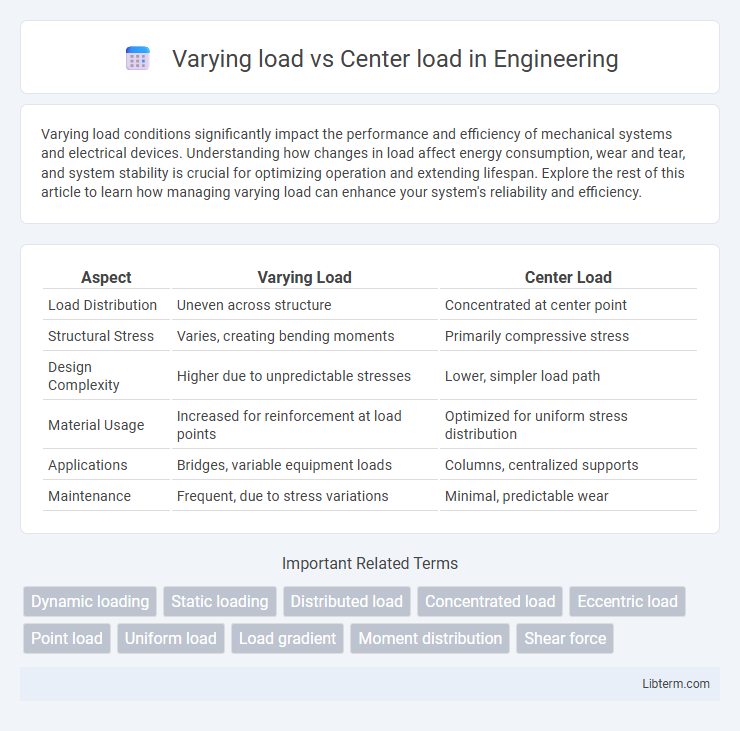

Table of Comparison

| Aspect | Varying Load | Center Load |

|---|---|---|

| Load Distribution | Uneven across structure | Concentrated at center point |

| Structural Stress | Varies, creating bending moments | Primarily compressive stress |

| Design Complexity | Higher due to unpredictable stresses | Lower, simpler load path |

| Material Usage | Increased for reinforcement at load points | Optimized for uniform stress distribution |

| Applications | Bridges, variable equipment loads | Columns, centralized supports |

| Maintenance | Frequent, due to stress variations | Minimal, predictable wear |

Understanding Varying Load and Center Load

Understanding varying load involves analyzing how changing forces or weights impact structural elements or mechanical systems over time, requiring careful assessment to ensure stability and durability. Center load refers to the application of force or weight concentrated at the geometric center of an object or structure, which influences stress distribution and balance differently compared to off-center or varying loads. Accurate evaluation of both varying and center loads is crucial in engineering design to optimize safety, performance, and material efficiency.

Defining Key Concepts: Varying Load vs Center Load

Varying load refers to the fluctuating distribution of forces applied unevenly across a structure or system, causing dynamic stress changes over time. Center load denotes a concentrated force applied precisely at the central axis or midpoint of an object, resulting in symmetric stress distribution. Understanding these key concepts is essential for optimizing structural integrity and performance in engineering designs.

Applications in Structural Engineering

Varying load applications in structural engineering address dynamic forces such as wind, traffic, and seismic activities that fluctuate over time, requiring flexible design solutions to maintain stability and safety. Center load scenarios focus on concentrated forces applied at a single point, commonly encountered in columns, beams, and foundation supports, necessitating precise stress analysis to prevent localized failure. Engineers use different computational models and materials to optimize structures under these load conditions, enhancing durability and performance.

Impact on Load Distribution

Varying load causes uneven stress distribution across structural elements, leading to localized overloads and potential deformation or failure points. Center load ensures a more uniform load distribution, minimizing bending moments and shear forces within beams or foundations. Optimizing load placement enhances structural integrity by reducing peak stresses and improving overall stability in engineering applications.

Effects on Material Strength and Performance

Varying load conditions cause fluctuating stress distribution within materials, often leading to fatigue and microstructural degradation, which reduce overall material strength and performance. Center load applications tend to produce more uniform stress distribution, enhancing structural integrity and minimizing localized deformation risks. Understanding the differing impacts of load patterns allows engineers to optimize material selection and design for durability and longevity under specific use conditions.

Design Considerations for Load Types

Design considerations for varying load versus center load emphasize structural stability and material distribution tailored to distinct stress patterns. Varying loads demand flexible support systems and reinforcement in multiple regions to accommodate fluctuating forces, whereas center loads require concentrated strength at a focal point to prevent deformation. Engineers optimize beam dimensions, support placement, and material selection based on load type to ensure durability and safety under operational conditions.

Calculating Stress in Varying and Center Loads

Calculating stress under varying load conditions requires integrating the load distribution over the structural element to determine the resultant stress at critical points, often using methods like linear or nonlinear stress analysis. Center load stress calculation simplifies to using the formula s = F/A, where F is the applied load and A is the cross-sectional area, assuming uniform stress distribution. Advanced techniques such as finite element analysis (FEA) can model both varying and center loads to provide precise stress variation and maximum stress concentration locations.

Common Mistakes in Load Placement

Incorrect load placement often occurs when varying load distribution is treated the same as center load conditions, leading to imbalance and structural stress. Many assume the load always centers uniformly, ignoring off-center concentrations that cause uneven weight distribution and potential damage. Proper assessment of load type and precise positioning prevents structural failure and enhances overall stability.

Real-world Examples and Case Studies

Varying load systems adapt to fluctuating demands in sectors like manufacturing, where equipment operates at different capacities throughout production cycles, ensuring energy efficiency and cost savings. Center load configurations, common in data centers, distribute power uniformly across critical servers, optimizing performance and minimizing downtime. Case studies in smart grids reveal that varying load strategies reduce peak energy usage by up to 30%, while center load setups enhance system reliability by balancing load distribution evenly.

Best Practices for Load Optimization

Varying load optimization emphasizes distributing weight to adapt to changing conditions, enhancing vehicle stability and fuel efficiency. Center load techniques focus on centralized weight placement to improve balance and reduce strain on suspension components. Best practices for load optimization include consistently monitoring weight distribution, using load sensors, and adjusting cargo positioning to maintain optimal center of gravity for safety and performance.

Varying load Infographic

libterm.com

libterm.com