Powder bed fusion is an advanced additive manufacturing technique that uses a laser or electron beam to selectively melt and fuse powder particles layer by layer, creating complex and precise 3D parts. This process offers exceptional accuracy, material efficiency, and the ability to produce intricate geometries that are difficult to achieve with traditional manufacturing methods. Discover how powder bed fusion can revolutionize your production capabilities by exploring the detailed insights in the rest of this article.

Table of Comparison

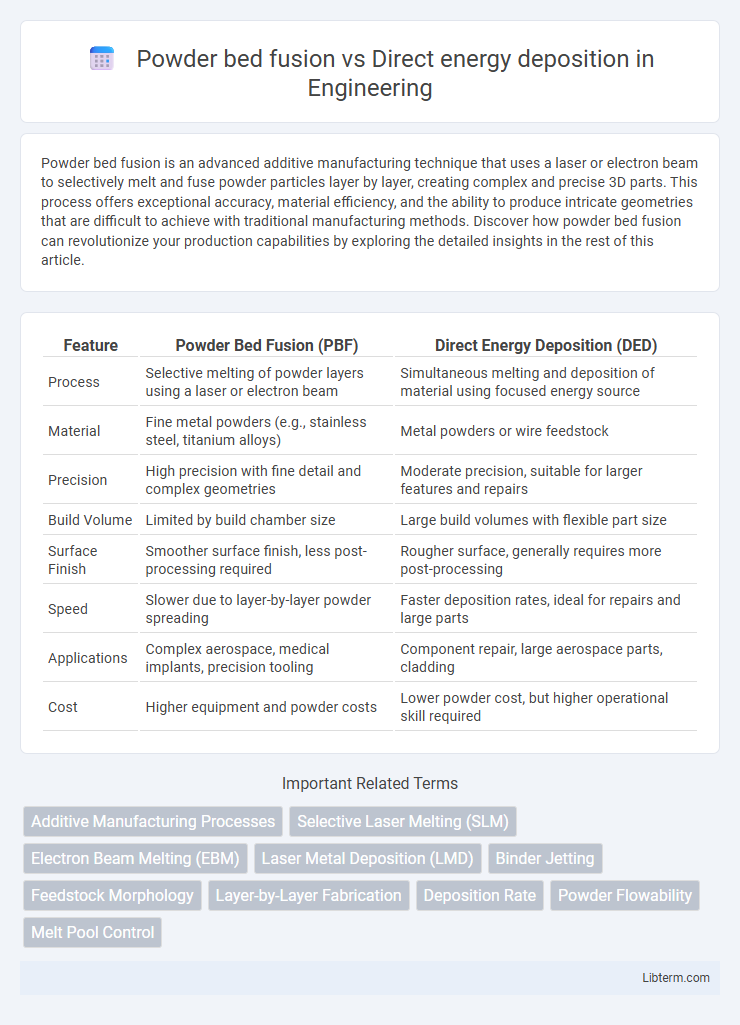

| Feature | Powder Bed Fusion (PBF) | Direct Energy Deposition (DED) |

|---|---|---|

| Process | Selective melting of powder layers using a laser or electron beam | Simultaneous melting and deposition of material using focused energy source |

| Material | Fine metal powders (e.g., stainless steel, titanium alloys) | Metal powders or wire feedstock |

| Precision | High precision with fine detail and complex geometries | Moderate precision, suitable for larger features and repairs |

| Build Volume | Limited by build chamber size | Large build volumes with flexible part size |

| Surface Finish | Smoother surface finish, less post-processing required | Rougher surface, generally requires more post-processing |

| Speed | Slower due to layer-by-layer powder spreading | Faster deposition rates, ideal for repairs and large parts |

| Applications | Complex aerospace, medical implants, precision tooling | Component repair, large aerospace parts, cladding |

| Cost | Higher equipment and powder costs | Lower powder cost, but higher operational skill required |

Introduction to Powder Bed Fusion and Direct Energy Deposition

Powder Bed Fusion (PBF) is an additive manufacturing process that selectively melts or fuses powder particles layer by layer using a high-energy heat source, such as a laser or electron beam, to create precise and complex metal parts with excellent surface finish and mechanical properties. Direct Energy Deposition (DED) involves melting material as it is deposited, using focused thermal energy like a laser or electron beam, allowing for the repair, addition, or fabrication of metal components with high deposition rates and the ability to work with multiple materials. Both technologies serve critical roles in advanced manufacturing, with PBF excelling in detail and accuracy, while DED offers versatility and efficiency for larger or multi-material parts.

Fundamental Principles of Powder Bed Fusion

Powder bed fusion (PBF) uses a finely controlled laser or electron beam to selectively melt and fuse powder particles layer by layer, creating highly detailed and precise metal parts with complex geometries. This process relies on a thin bed of powder spread uniformly across the build platform, where energy absorption and rapid solidification dictate microstructure and mechanical properties. In contrast, direct energy deposition (DED) feeds material directly into a molten pool generated by a laser, electron beam, or plasma arc, enabling faster build rates but generally with less intricate detail and surface finish compared to PBF.

Direct Energy Deposition: Process Overview

Direct Energy Deposition (DED) is an additive manufacturing process where focused thermal energy, such as a laser, electron beam, or plasma arc, melts materials as they are deposited, typically in powder or wire form, allowing for precise material placement and repair applications. This technique excels in creating large-scale metal parts with complex geometries and enables the addition of features to existing components, offering high build rates compared to Powder Bed Fusion (PBF). DED systems integrate real-time monitoring and control to optimize layer quality, material properties, and minimize defects during the fabrication process.

Materials Compatibility in Both Methods

Powder bed fusion (PBF) offers high compatibility with a wide range of metals and alloys, including titanium, stainless steel, and aluminum, due to its precise thermal control and fine powder distribution. Direct energy deposition (DED) excels in repairing and adding material to existing components with materials like superalloys and refractory metals, but typically handles a narrower range of powders and wire feedstocks than PBF. Both methods demand thorough material characterization to optimize parameters for phase stability, microstructure, and mechanical properties, with PBF favoring fine powders and DED accommodating larger particles and mixed-material feedstocks.

Accuracy and Surface Finish Comparison

Powder bed fusion (PBF) offers superior accuracy and finer surface finish due to its high-resolution laser control and layer-by-layer powder fusion, achieving tolerances often within +-0.1 mm. Direct energy deposition (DED) typically produces rougher surfaces and lower dimensional precision, with tolerances around +-0.5 mm, attributed to the material melting and solidification process involving a molten pool. PBF is preferred for intricate geometries demanding detailed features and smooth finishes, while DED suits larger parts where surface finish can be improved through post-processing.

Build Speed and Productivity Analysis

Powder Bed Fusion (PBF) offers high precision but generally has slower build speeds compared to Direct Energy Deposition (DED), which excels in rapid material addition and large-scale part manufacturing. DED technology supports higher deposition rates, significantly enhancing productivity for repair and large component fabrication, whereas PBF is better suited for intricate geometries and fine details. Evaluating build speed and productivity highlights DED's advantage in volume throughput while PBF maintains superior surface finish and resolution.

Applications and Industry Use Cases

Powder bed fusion (PBF) excels in producing high-precision components for aerospace, medical implants, and intricate tooling, offering superior surface finish and complex geometries. Direct energy deposition (DED) is widely used in repair applications, large metal part manufacturing, and adding features to existing components in heavy industries such as automotive and defense. Both technologies serve additive manufacturing but PBF targets detailed, smaller-scale parts while DED supports larger, functional repairs and hybrid manufacturing workflows.

Cost Considerations: Equipment and Operation

Powder bed fusion (PBF) systems generally involve higher initial equipment costs due to their advanced laser optics and precise powder handling, while direct energy deposition (DED) machines tend to be less expensive but require more skilled labor for operation and maintenance. Operational costs for PBF include extensive powder recycling and strict environmental controls, increasing ongoing expenses, whereas DED often incurs lower material costs but higher labor and post-processing costs due to less precision. Overall, PBF is more cost-effective for complex geometries and small batch production, whereas DED offers cost advantages for large-scale repair and additive-subtractive hybrid manufacturing.

Advancements and Innovations in Both Technologies

Powder bed fusion (PBF) advancements focus on enhanced laser precision and improved powder recycling techniques, enabling finer resolution and reduced material waste. Direct energy deposition (DED) innovations highlight real-time monitoring systems and multi-material capabilities, allowing greater process control and complex part fabrication. Both technologies benefit from AI integration and novel alloy development, accelerating production efficiency and expanding application scopes in aerospace and medical industries.

Selecting the Right Method: Key Decision Factors

Selecting the right additive manufacturing method between Powder Bed Fusion (PBF) and Direct Energy Deposition (DED) depends heavily on material compatibility, part complexity, and desired mechanical properties. PBF excels in producing high-resolution, intricate components with superior surface finish, ideal for aerospace and medical applications. DED offers advantages in repair and large-scale fabrication due to its higher deposition rates and ability to work with multiple materials, making it suitable for heavy equipment and tooling industries.

Powder bed fusion Infographic

libterm.com

libterm.com