Reed relays are electromagnetic switches that use thin magnetic reeds sealed within a glass tube, providing fast switching times and high reliability in low-level signal applications. Their hermetically sealed design ensures long-term performance by preventing contamination and corrosion in sensitive circuits. Explore the rest of the article to understand how reed relays can enhance Your electronic projects with precision and durability.

Table of Comparison

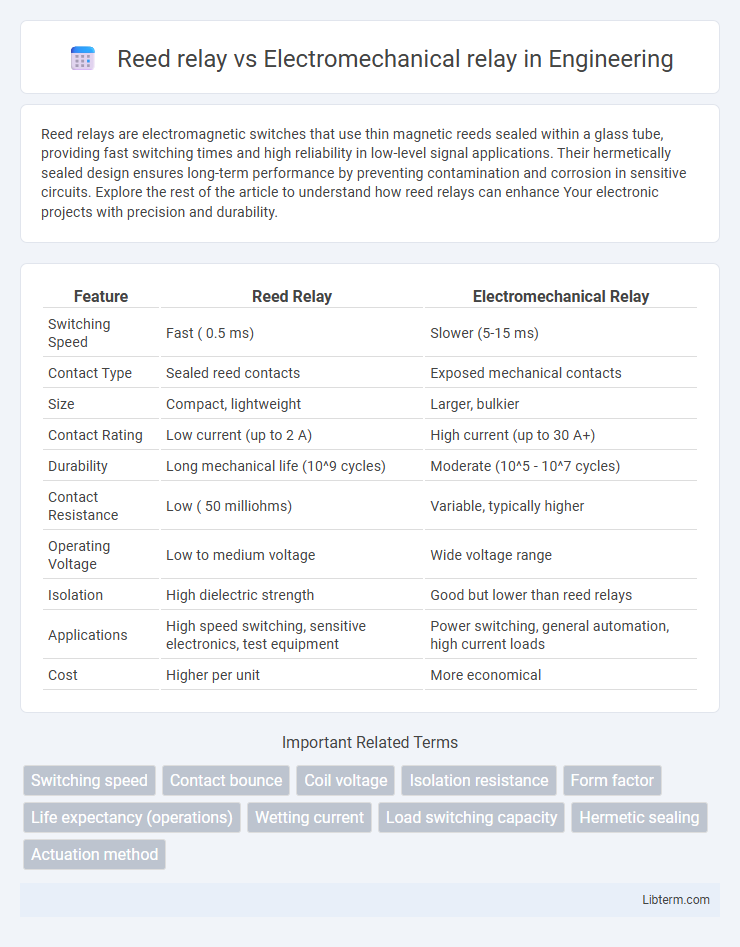

| Feature | Reed Relay | Electromechanical Relay |

|---|---|---|

| Switching Speed | Fast ( 0.5 ms) | Slower (5-15 ms) |

| Contact Type | Sealed reed contacts | Exposed mechanical contacts |

| Size | Compact, lightweight | Larger, bulkier |

| Contact Rating | Low current (up to 2 A) | High current (up to 30 A+) |

| Durability | Long mechanical life (10^9 cycles) | Moderate (10^5 - 10^7 cycles) |

| Contact Resistance | Low ( 50 milliohms) | Variable, typically higher |

| Operating Voltage | Low to medium voltage | Wide voltage range |

| Isolation | High dielectric strength | Good but lower than reed relays |

| Applications | High speed switching, sensitive electronics, test equipment | Power switching, general automation, high current loads |

| Cost | Higher per unit | More economical |

Introduction to Reed Relays and Electromechanical Relays

Reed relays consist of thin, ferromagnetic reeds enclosed in a glass capsule that close or open contacts when subjected to a magnetic field, allowing for fast switching and low contact resistance. Electromechanical relays use a coil to create an electromagnetic field that mechanically moves a set of contacts to open or close a circuit, offering higher current capacity but slower response times. Reed relays excel in high-speed, low-power applications, while electromechanical relays are preferred for handling higher loads and more rugged switching environments.

Basic Working Principles

Reed relays operate using a pair of ferromagnetic reeds enclosed in a glass tube that close the circuit when exposed to a magnetic field generated by a coil. Electromechanical relays function by energizing an electromagnet to mechanically move a set of contacts, opening or closing the circuit. Reed relays offer faster switching speeds and longer lifespans due to their sealed construction, whereas electromechanical relays provide higher current handling and more robust contact configurations.

Key Differences in Construction

Reed relays use thin, magnetically sensitive metal reeds sealed in a glass envelope, offering fast switching and low power consumption, while electromechanical relays contain larger, mechanically moving contacts operated by an electromagnetic coil for switching higher currents. Reed relay contacts are hermetically sealed, providing excellent protection against environmental contaminants, unlike electromechanical relays that typically have open contacts exposed to the atmosphere. The compact and lightweight construction of reed relays contrasts with the bulkier, more robust frame of electromechanical relays designed for durability in heavy-duty applications.

Speed of Operation

Reed relays operate with significantly faster switching times, typically in the range of 0.5 to 1 millisecond, due to their lightweight reed contacts and compact construction. Electromechanical relays generally have slower switching speeds, usually around 5 to 20 milliseconds, as their larger mechanical components require more time to move. This speed advantage makes reed relays ideal for high-frequency switching applications and precise signal control.

Power Consumption Comparison

Reed relays consume significantly less power than electromechanical relays due to their sealed, lightweight design and low coil current requirements, typically in the range of 10-20 mW. Electromechanical relays often require higher coil power, usually between 500 mW to 2 W, resulting in greater energy usage during operation. This difference makes reed relays ideal for battery-powered or energy-sensitive applications where minimizing power consumption is crucial.

Reliability and Lifespan

Reed relays offer higher reliability and significantly longer lifespan due to their sealed contacts, which resist contamination and reduce wear over millions of switching cycles. Electromechanical relays rely on mechanical contacts exposed to air, resulting in faster contact degradation, contact bounce, and limited operational cycles. Reed relays excel in applications requiring low-level signal switching with consistent performance over time, while electromechanical relays are more suited for higher current loads but have shorter service life and higher maintenance needs.

Size and Packaging Options

Reed relays are significantly smaller than electromechanical relays, typically measuring only a few millimeters, making them ideal for compact electronic circuits where space is limited. They are enclosed in hermetically sealed glass tubes, providing excellent protection against environmental factors and allowing for surface-mount packaging options. In contrast, electromechanical relays are larger, often in molded plastic or metal cases, and usually available in through-hole or panel-mount formats, which restrict their use in miniature or densely packed applications.

Typical Applications

Reed relays are commonly used in testing equipment, telecommunications, and medical devices due to their fast switching speeds, low contact capacitance, and long operational life. Electromechanical relays find typical applications in automation systems, industrial control panels, and automotive circuits because of their ability to handle higher currents and voltages. Reed relays excel in signal switching and low power applications, whereas electromechanical relays are preferred for power switching and load control tasks.

Cost Considerations

Reed relays generally have a higher initial cost compared to electromechanical relays due to their precise internal construction and sealed contacts, which ensure long-term reliability and fast switching. Electromechanical relays offer a cost-effective solution for applications requiring high current switching but may incur higher maintenance costs over time due to contact wear and mechanical fatigue. Evaluating total cost of ownership involves considering factors such as expected switching frequency, load requirements, and maintenance intervals alongside the upfront purchase price.

Choosing the Right Relay for Your Application

Choosing the right relay for your application depends on factors like switching speed, contact life, and load type. Reed relays offer faster switching times and longer contact life, making them ideal for low current, high-precision signals, while electromechanical relays handle higher voltage and current loads with greater robustness. Consider environmental conditions and required durability to ensure optimal performance and reliability in your specific use case.

Reed relay Infographic

libterm.com

libterm.com