Manual systems rely on human intervention for operation, often resulting in slower processes and increased risk of errors compared to automated solutions. These systems are common in various industries but can limit efficiency and scalability due to their dependency on manual input. Discover how transitioning from manual systems to automated technologies can transform your workflow and improve productivity in the rest of this article.

Table of Comparison

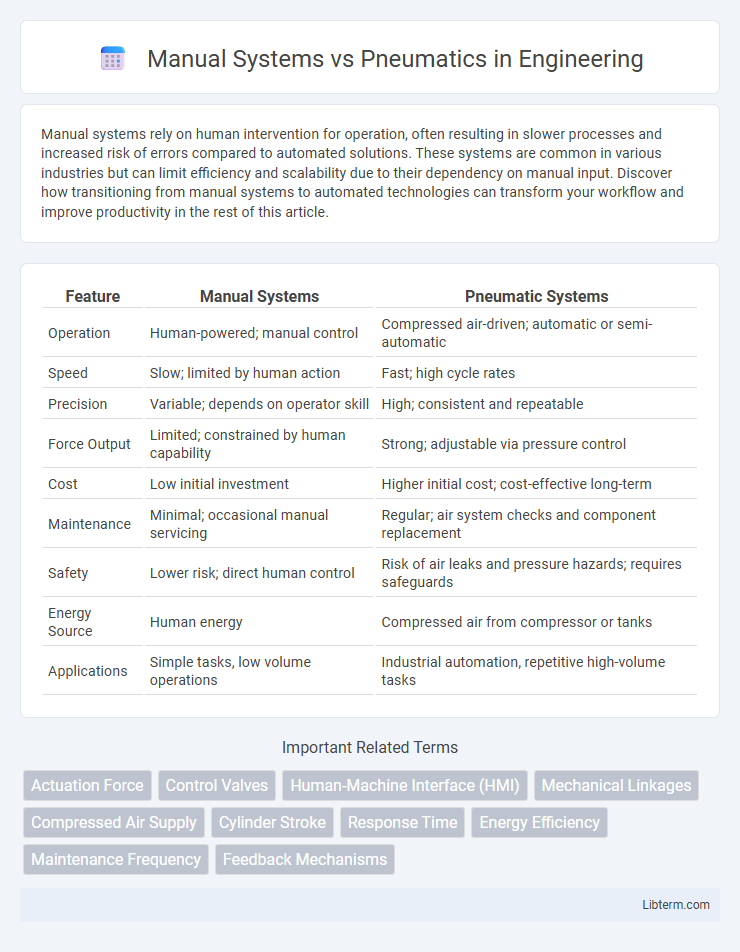

| Feature | Manual Systems | Pneumatic Systems |

|---|---|---|

| Operation | Human-powered; manual control | Compressed air-driven; automatic or semi-automatic |

| Speed | Slow; limited by human action | Fast; high cycle rates |

| Precision | Variable; depends on operator skill | High; consistent and repeatable |

| Force Output | Limited; constrained by human capability | Strong; adjustable via pressure control |

| Cost | Low initial investment | Higher initial cost; cost-effective long-term |

| Maintenance | Minimal; occasional manual servicing | Regular; air system checks and component replacement |

| Safety | Lower risk; direct human control | Risk of air leaks and pressure hazards; requires safeguards |

| Energy Source | Human energy | Compressed air from compressor or tanks |

| Applications | Simple tasks, low volume operations | Industrial automation, repetitive high-volume tasks |

Understanding Manual Systems: An Overview

Manual systems rely on human effort to operate machinery or equipment, providing direct control and tactile feedback for precise movements. These systems are often simpler, cost-effective, and require minimal maintenance compared to automated alternatives. Understanding the mechanics of levers, gears, and basic hydraulic components is essential for optimizing manual operation and ensuring safety in various industrial applications.

What Are Pneumatic Systems?

Pneumatic systems use compressed air to transmit and control energy, enabling automation in industrial applications. These systems consist of components such as compressors, cylinders, valves, and actuators that work together to perform mechanical tasks with precision and speed. Unlike manual systems, pneumatic systems offer higher efficiency, improved safety, and consistent performance in repetitive operations.

Key Components of Manual and Pneumatic Systems

Key components of manual systems include levers, gears, and valves operated by human force, enabling direct control over mechanical processes. Pneumatic systems consist of compressors, air tanks, actuators, and control valves that utilize compressed air to generate motion or force. Both systems rely on actuators and control elements, but pneumatic systems offer enhanced automation and faster response times due to air pressure-driven operation.

How Manual Systems Operate

Manual systems operate through direct human intervention, where physical force is applied to control mechanisms such as levers, valves, or switches. These systems rely on mechanical advantage and human dexterity to perform tasks without the need for external power sources like electricity or compressed air. The simplicity of manual operation ensures reliability in environments where automation or pneumatics are impractical or unavailable.

The Working Principles of Pneumatic Systems

Pneumatic systems operate using compressed air to transmit and control energy, relying on components like compressors, valves, and actuators to convert air pressure into mechanical motion. The working principle involves the intake of compressed air which expands and exerts force on a piston or diaphragm, generating linear or rotary movement. Compared to manual systems, pneumatic systems offer faster, more precise, and automated control with minimal physical effort and higher repeatability in industrial applications.

Efficiency Comparison: Manual vs Pneumatics

Manual systems rely heavily on human effort, resulting in lower efficiency and slower operational cycles compared to pneumatics, which utilize compressed air to deliver consistent power and speed. Pneumatic systems reduce downtime through automation and minimize human error, significantly improving productivity in industrial processes. Energy consumption in pneumatics is higher, but the trade-off in enhanced throughput and precision often justifies the investment over manual methods.

Cost Analysis: Initial Investment and Maintenance

Manual systems typically require lower initial investment costs due to simpler components and lack of complex machinery, making them budget-friendly for small-scale operations. Pneumatic systems involve higher upfront expenses for compressors, valves, and control units but offer reduced long-term maintenance costs by minimizing wear through automation. Maintenance for manual systems often demands frequent labor and part replacements, while pneumatic systems benefit from streamlined upkeep that enhances operational efficiency.

Operational Safety: Manual vs Pneumatic Solutions

Manual systems require direct human intervention, increasing the risk of operator error and physical injury, while pneumatic systems offer automated control that reduces such hazards by minimizing manual handling. Pneumatic solutions incorporate safety valves, pressure regulators, and emergency stop mechanisms, which enhance operational safety by preventing overpressure and system failures. The controlled and consistent performance of pneumatic systems significantly lowers accident rates compared to manual operations.

Applications and Industry Usage

Manual systems excel in low-volume, precision tasks such as assembly in electronics and small-scale manufacturing, offering simple operation without complex infrastructure. Pneumatics dominate industries like automotive, food processing, and packaging, where rapid, repetitive motion and durability under harsh conditions are essential. Pneumatic systems provide higher automation potential and efficiency in large-scale manufacturing environments compared to manual mechanisms.

Choosing the Right System: Manual or Pneumatics?

Choosing between manual systems and pneumatics depends on factors such as operational speed, precision, and maintenance requirements. Manual systems offer simplicity and cost-effectiveness for low-volume or straightforward tasks, while pneumatics provide higher efficiency, automation capabilities, and consistent force for industrial applications. Evaluating workload, environmental conditions, and budget constraints helps determine the optimal system for specific use cases.

Manual Systems Infographic

libterm.com

libterm.com