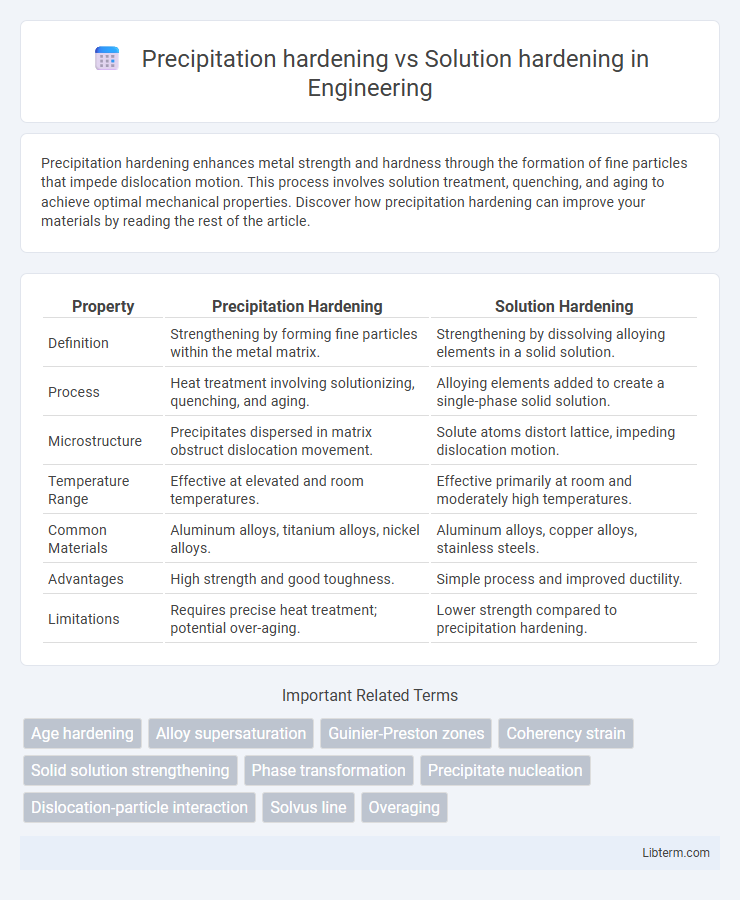

Precipitation hardening enhances metal strength and hardness through the formation of fine particles that impede dislocation motion. This process involves solution treatment, quenching, and aging to achieve optimal mechanical properties. Discover how precipitation hardening can improve your materials by reading the rest of the article.

Table of Comparison

| Property | Precipitation Hardening | Solution Hardening |

|---|---|---|

| Definition | Strengthening by forming fine particles within the metal matrix. | Strengthening by dissolving alloying elements in a solid solution. |

| Process | Heat treatment involving solutionizing, quenching, and aging. | Alloying elements added to create a single-phase solid solution. |

| Microstructure | Precipitates dispersed in matrix obstruct dislocation movement. | Solute atoms distort lattice, impeding dislocation motion. |

| Temperature Range | Effective at elevated and room temperatures. | Effective primarily at room and moderately high temperatures. |

| Common Materials | Aluminum alloys, titanium alloys, nickel alloys. | Aluminum alloys, copper alloys, stainless steels. |

| Advantages | High strength and good toughness. | Simple process and improved ductility. |

| Limitations | Requires precise heat treatment; potential over-aging. | Lower strength compared to precipitation hardening. |

Introduction to Metallurgical Hardening Techniques

Precipitation hardening enhances metal strength by forming fine, dispersed particles that impede dislocation motion, typically involving heat treatment steps like aging and quenching. Solution hardening increases hardness by dissolving alloying elements into the base metal's crystal lattice, creating lattice distortions that hinder dislocation movement. Both methods are fundamental metallurgical hardening techniques used to improve mechanical properties in alloys such as aluminum, titanium, and stainless steel.

Overview of Precipitation Hardening

Precipitation hardening, also known as age hardening, is a heat treatment process that strengthens alloys by forming fine, dispersed particles within the metal matrix, which hinder dislocation movement and improve mechanical properties. It involves three key steps: solution treatment, quenching, and aging, allowing controlled precipitation of secondary phases like intermetallic compounds in aluminum, titanium, and nickel-based alloys. This method offers superior strength and hardness compared to solution hardening, which relies solely on alloying element dissolution to impede dislocations without forming distinct precipitates.

Fundamentals of Solution Hardening

Solution hardening strengthens alloys by dissolving solute atoms into a solvent metal, creating lattice distortions that impede dislocation movement and enhance mechanical properties. The fundamental mechanism relies on atomic size differences and elastic strain fields generated by solute atoms, which increase resistance to plastic deformation. This method differs from precipitation hardening, which forms discrete secondary phase particles to obstruct dislocations, making solution hardening a primary approach for solid-solution alloys like copper-nickel or aluminum-magnesium.

Mechanisms of Strengthening in Alloys

Precipitation hardening strengthens alloys by forming finely dispersed particles within the metal matrix that hinder dislocation movement, enhancing yield strength and hardness through coherent or semi-coherent particle-matrix interfaces. Solution hardening increases strength by introducing solute atoms that create lattice strain fields, impeding dislocation motion via elastic distortions in the crystal structure. The effectiveness of precipitation hardening depends on particle size, distribution, and coherence, while solution hardening relies on the type, concentration, and size mismatch of solute atoms in the solvent lattice.

Key Differences: Precipitation vs Solution Hardening

Precipitation hardening involves the formation of fine, dispersed particles within the metal matrix that obstruct dislocation movement, enhancing strength and hardness through controlled heat treatment. Solution hardening, on the other hand, improves mechanical properties by dissolving alloying elements into the base metal, creating a solid solution that distorts the lattice and impedes dislocations without separate particle formation. The key difference lies in precipitation hardening relying on the nucleation and growth of second-phase particles, whereas solution hardening depends on atomic-level alloying element distribution within the primary phase.

Applications of Precipitation Hardened Materials

Precipitation hardened materials are widely used in aerospace, automotive, and defense industries due to their superior strength-to-weight ratio and excellent fatigue resistance. These alloys, such as aluminum-copper and nickel-based superalloys, enhance mechanical properties through finely dispersed precipitates that impede dislocation movement. Common applications include turbine blades, aircraft structural components, and high-performance engine parts where durability and lightweight characteristics are critical.

Typical Uses of Solution Hardened Alloys

Solution hardened alloys are widely used in aerospace components, automotive parts, and industrial machinery due to their enhanced strength and corrosion resistance achieved by dissolving alloying elements uniformly within the metal matrix. These alloys, such as aluminum-copper and stainless steel grades, maintain improved mechanical properties at elevated temperatures, making them ideal for structural and high-stress applications. Their typical uses also extend to marine environments and chemical processing equipment where resistance to wear and oxidation is critical.

Advantages and Limitations of Each Method

Precipitation hardening offers significant strength improvement by forming fine, dispersed particles within the metal matrix, enhancing mechanical properties such as yield strength and hardness; however, it requires precise heat treatment processes and can lead to reduced ductility. Solution hardening increases alloy strength by dissolving solute atoms in the matrix to create lattice distortions that impede dislocation motion, providing uniform strengthening without phase changes but often results in lower maximum strength compared to precipitation hardening. Both methods balance trade-offs between hardness, workability, and processing complexity, influencing their selection for applications in aerospace, automotive, and structural materials.

Selection Criteria for Industrial Applications

Selection criteria for industrial applications favor precipitation hardening when enhanced strength and toughness are required without compromising ductility, as it forms fine, dispersed precipitates that hinder dislocation motion effectively. Solution hardening is preferred in environments demanding elevated corrosion resistance and uniform solid-solution properties, as alloying elements dissolve directly in the matrix, improving strength through lattice distortion. Material compatibility, heat treatment capabilities, and cost-effectiveness are critical factors influencing the choice between precipitation hardening and solution hardening techniques.

Future Trends in Metallurgical Hardening Techniques

Future trends in metallurgical hardening techniques emphasize the integration of precipitation hardening and solution hardening to achieve superior mechanical properties and microstructural control. Advanced alloy design using computational methods enables precise manipulation of solute atoms and precipitate phases, enhancing strength and ductility in aerospace and automotive applications. Nanostructured materials and additive manufacturing further drive innovations by enabling tailored hardening mechanisms at multiple scales for next-generation performance.

Precipitation hardening Infographic

libterm.com

libterm.com