PROFINET is an open standard for industrial Ethernet that ensures real-time data exchange between controllers and devices in automation systems. This technology enhances manufacturing efficiency by providing fast communication, scalability, and seamless integration with existing industrial networks. Explore the following article to understand how PROFINET can optimize your industrial automation processes.

Table of Comparison

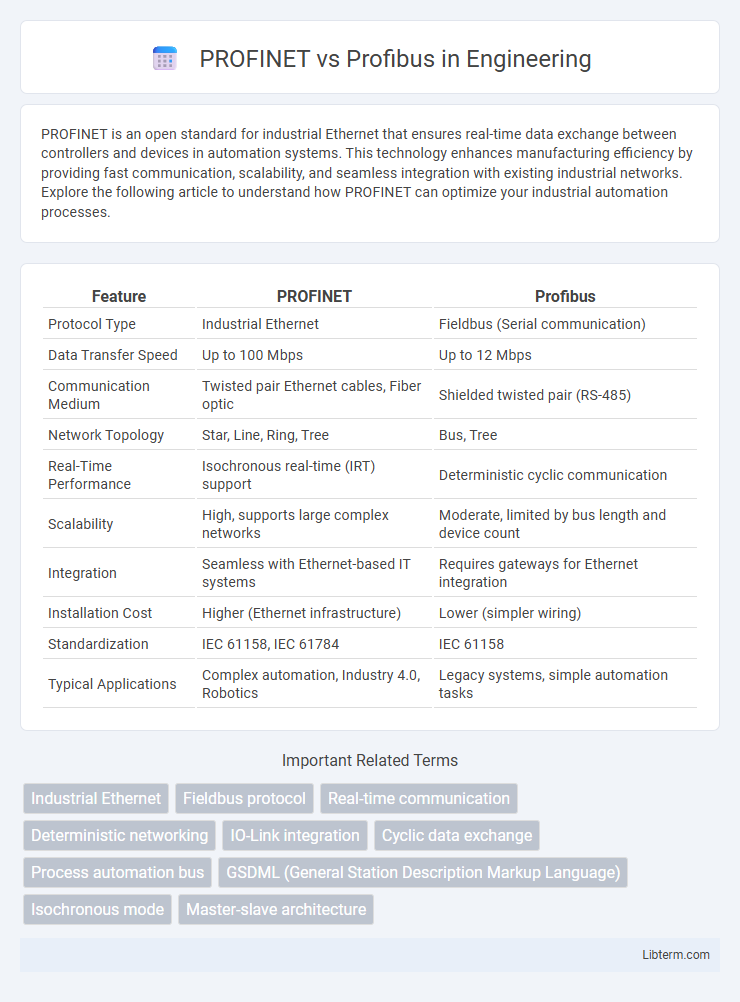

| Feature | PROFINET | Profibus |

|---|---|---|

| Protocol Type | Industrial Ethernet | Fieldbus (Serial communication) |

| Data Transfer Speed | Up to 100 Mbps | Up to 12 Mbps |

| Communication Medium | Twisted pair Ethernet cables, Fiber optic | Shielded twisted pair (RS-485) |

| Network Topology | Star, Line, Ring, Tree | Bus, Tree |

| Real-Time Performance | Isochronous real-time (IRT) support | Deterministic cyclic communication |

| Scalability | High, supports large complex networks | Moderate, limited by bus length and device count |

| Integration | Seamless with Ethernet-based IT systems | Requires gateways for Ethernet integration |

| Installation Cost | Higher (Ethernet infrastructure) | Lower (simpler wiring) |

| Standardization | IEC 61158, IEC 61784 | IEC 61158 |

| Typical Applications | Complex automation, Industry 4.0, Robotics | Legacy systems, simple automation tasks |

Introduction to PROFINET and Profibus

PROFINET and Profibus are industrial communication protocols widely used for automation systems, with PROFINET leveraging Ethernet for faster, real-time data exchange compared to the fieldbus technology of Profibus. PROFINET supports seamless integration with Industry 4.0 and IIoT applications through high-speed, deterministic communication, while Profibus remains reliable for legacy systems with robust serial communication. Both protocols facilitate device interoperability and system diagnostics but differ significantly in network architecture, speed, and scalability.

Key Differences Between PROFINET and Profibus

PROFINET operates over standard Ethernet, providing higher data transfer rates up to 100 Mbps and supporting real-time communication essential for Industry 4.0 applications, whereas Profibus uses serial communication with speeds up to 12 Mbps, making it suitable for legacy systems. PROFINET offers greater flexibility with seamless integration of wireless devices and direct Internet connectivity, contrasting with Profibus's reliance on specialized cabling and limited topologies. The enhanced diagnostics and network management capabilities of PROFINET improve maintenance efficiency and system reliability compared to the more static monitoring options available in Profibus.

Communication Protocols: Ethernet vs Serial

PROFINET utilizes Ethernet as its communication protocol, enabling high-speed data transfer, real-time communication, and seamless integration with IT networks. Profibus relies on serial communication, specifically RS-485, which offers robust, deterministic data transmission but at lower speeds compared to Ethernet. The shift from Profibus to PROFINET reflects industry trends favoring Ethernet's scalability, bandwidth, and compatibility with modern automation systems.

Network Topologies and Scalability

PROFINET supports flexible network topologies including line, star, and ring configurations, enabling robust redundancy options such as Media Redundancy Protocol (MRP) for high availability. Profibus primarily uses a bus topology, which limits scalability and redundancy compared to PROFINET's Ethernet-based infrastructure. PROFINET's scalability extends to thousands of nodes with high-speed communication, making it suitable for complex industrial automation systems, whereas Profibus is more constrained by slower serial communication and fewer devices per segment.

Data Transmission Speeds and Performance

PROFINET offers significantly higher data transmission speeds compared to Profibus, with PROFINET supporting up to 100 Mbps or more over Ethernet, while Profibus typically operates at speeds up to 12 Mbps. PROFINET's real-time communication capabilities enable faster and more reliable data exchange for complex industrial automation systems, enhancing overall performance. The advanced performance of PROFINET makes it ideal for applications requiring high-speed data transfer and low latency in modern manufacturing environments.

Determinism and Real-Time Capabilities

PROFINET offers superior determinism and real-time capabilities compared to Profibus by utilizing Ethernet-based communication with prioritized data transfer and optimized real-time extensions like PROFINET IRT (Isochronous Real-Time), enabling cycle times as low as 31.25 us. Profibus, relying on serial communication, provides reasonable determinism with cycle times typically around 1 ms but lacks the high-precision synchronization and bandwidth scalability found in PROFINET. The enhanced real-time performance of PROFINET makes it ideal for applications requiring stringent timing constraints, such as motion control and high-speed automation processes.

Integration with Industrial Automation Systems

PROFINET offers superior integration with modern industrial automation systems due to its Ethernet-based architecture, enabling seamless real-time data exchange and higher network performance compared to the serial communication of Profibus. PROFINET supports complex topologies and diagnostics, enhancing flexibility and maintainability in automation networks. Its compatibility with Industry 4.0 standards and advanced cybersecurity features further strengthen its role in integrating diverse industrial devices and controllers.

Installation, Maintenance, and Troubleshooting

PROFINET offers simplified installation through standardized Ethernet cabling and plug-and-play configuration, contrasting with Profibus's reliance on specialized wiring and termination resistors that complicate setup. Maintenance is streamlined in PROFINET systems thanks to real-time diagnostics and network management tools that promptly identify device failures or connection issues, whereas Profibus requires manual testing and more frequent physical inspections. Troubleshooting PROFINET benefits from integrated diagnostic information accessible via standard Ethernet-based software, reducing downtime, while Profibus troubleshooting often involves specialized hardware tools to analyze signal quality and network integrity.

Security Considerations in Industrial Networks

PROFINET employs advanced security features such as TLS encryption, authentication, and network segmentation to protect industrial communication against cyber threats, while Profibus lacks inherent cybersecurity mechanisms, relying heavily on external measures. The integration of PROFINET with modern IT security protocols enhances its resilience to unauthorized access and data tampering, crucial for Industry 4.0 environments. In contrast, Profibus networks require additional protective layers like firewalls and VPNs to mitigate vulnerabilities stemming from its older serial communication design.

Future Trends and Industry Adoption

PROFINET is rapidly overtaking Profibus in industrial automation due to its Ethernet-based architecture, supporting higher data speeds and integration with Industrial Internet of Things (IIoT) technologies. Industry adoption trends indicate a growing preference for PROFINET in smart factories and Industry 4.0 environments, driven by enhanced diagnostic capabilities and real-time communication. While Profibus remains prevalent in legacy systems, the future points toward widespread migration to PROFINET for scalability and advanced automation applications.

PROFINET Infographic

libterm.com

libterm.com