Laser cutting offers precise, efficient, and versatile material shaping by using a focused laser beam to slice through metals, plastics, and other materials. This technology reduces waste, improves production speed, and delivers clean edges, making it ideal for manufacturing and design applications. Explore the rest of the article to discover how laser cutting can enhance your projects with unmatched accuracy and efficiency.

Table of Comparison

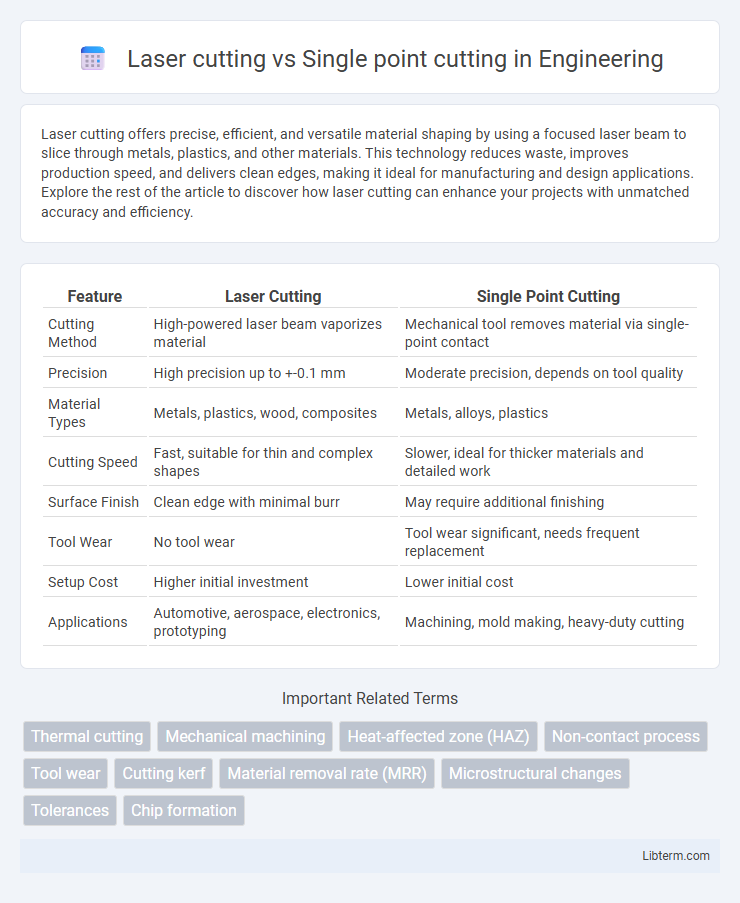

| Feature | Laser Cutting | Single Point Cutting |

|---|---|---|

| Cutting Method | High-powered laser beam vaporizes material | Mechanical tool removes material via single-point contact |

| Precision | High precision up to +-0.1 mm | Moderate precision, depends on tool quality |

| Material Types | Metals, plastics, wood, composites | Metals, alloys, plastics |

| Cutting Speed | Fast, suitable for thin and complex shapes | Slower, ideal for thicker materials and detailed work |

| Surface Finish | Clean edge with minimal burr | May require additional finishing |

| Tool Wear | No tool wear | Tool wear significant, needs frequent replacement |

| Setup Cost | Higher initial investment | Lower initial cost |

| Applications | Automotive, aerospace, electronics, prototyping | Machining, mold making, heavy-duty cutting |

Introduction to Laser Cutting and Single Point Cutting

Laser cutting utilizes a high-powered laser beam to precisely melt, burn, or vaporize material, enabling complex shapes and intricate designs with minimal waste and high speed. Single point cutting involves a single, sharp cutting tool that removes material mechanically through shear deformation, commonly used in turning and milling processes for simpler geometries. Laser cutting excels in non-contact precision and versatility across metals, plastics, and composites, whereas single point cutting is preferred for robust, mechanical shaping of metals with distinct tool paths.

Fundamental Principles of Each Cutting Method

Laser cutting utilizes a focused beam of coherent light to melt, burn, or vaporize material precisely along a programmed path, relying on high energy density and rapid thermal conduction for clean cuts. Single point cutting employs a mechanical tool that removes material through plastic deformation and shearing, where a sharp cutting edge interacts directly with the workpiece under controlled feed and speed parameters. The fundamental difference lies in the laser's non-contact energy delivery versus the physical interaction between the cutting tool and material in single point cutting.

Material Compatibility and Applications

Laser cutting offers superior compatibility with a wide range of materials including metals, plastics, wood, and fabrics, enabling precise and complex shapes ideal for aerospace, automotive, and electronics manufacturing. Single point cutting, primarily suited for metals and harder materials, excels in applications requiring high precision on cylindrical parts such as shafts and screws in machining and tooling industries. The choice between laser cutting and single point cutting depends on material hardness, thickness, and the specific industry requirements for accuracy and surface finish.

Precision and Tolerance Comparison

Laser cutting offers superior precision with tolerances typically within +-0.1 mm due to its non-contact process and minimal material distortion. Single point cutting achieves tolerance levels around +-0.05 mm but may introduce mechanical stress and tool wear affecting repeatability. The choice depends on required tolerance, material type, and surface finish, with laser cutting excelling in complex shapes and thin materials.

Cutting Speed and Efficiency

Laser cutting offers significantly higher cutting speeds compared to single point cutting, enabling rapid processing of complex shapes and thin materials with minimal mechanical force. Single point cutting, relying on a single cutting edge, provides precise material removal but is slower due to mechanical limitations and the need for multiple passes on hard or thick materials. Efficiency in laser cutting is enhanced by reduced tool wear and non-contact operation, whereas single point cutting requires frequent tool maintenance and slower feed rates to preserve accuracy.

Surface Finish Quality Differences

Laser cutting produces a highly precise, smooth surface finish with minimal burr and heat-affected zones, making it ideal for complex shapes and thin materials. Single point cutting often results in a rougher surface due to tool marks and requires post-processing for fine finishes, especially on harder materials. The choice between laser and single point cutting depends on desired surface finish quality and material thickness.

Equipment and Operational Costs

Laser cutting requires advanced laser systems with high initial investment and maintenance costs, while single point cutting relies on simpler mechanical tools with lower upfront expenses. Operational costs for laser cutting include electricity consumption and specialized operator training, contrasted with the relatively minimal energy and training requirements for single point cutting. Despite higher equipment costs, laser cutting often reduces labor and material waste, potentially offsetting operational expenses in high-volume production.

Safety and Environmental Considerations

Laser cutting significantly reduces workplace hazards by minimizing direct contact with sharp tools and eliminating the risk of blade breakage, while single point cutting involves greater operator exposure to mechanical injuries. Laser systems produce fewer airborne contaminants compared to single point cutting, which generates more metal chips and dust that require proper disposal to prevent environmental harm. The energy consumption of laser cutting is generally higher, but it offers cleaner processing with less material waste, contributing to more sustainable manufacturing practices.

Maintenance and Operational Requirements

Laser cutting machines require regular maintenance of optics, cooling systems, and laser sources to ensure precision and avoid downtime, while single point cutting tools demand frequent tool sharpening, alignment checks, and replacement due to wear. Operationally, laser cutting offers faster processing speeds and reduced manual intervention, but requires skilled monitoring of laser parameters and safety protocols. Single point cutting involves more mechanical adjustments and operator expertise to maintain consistent quality, impacting operational efficiency and maintenance frequency.

Choosing the Right Cutting Method for Your Project

Laser cutting offers precision and speed ideal for intricate designs and thin materials, whereas single point cutting excels in heavy-duty machining and creating complex 3D shapes. Selecting the right cutting method depends on factors like material type, thickness, desired tolerance, and production volume. For projects requiring high accuracy and minimal material distortion, laser cutting is preferable, while single point cutting suits tasks demanding robustness and versatility.

Laser cutting Infographic

libterm.com

libterm.com