Shore hardness measures the resistance of a material to indentation, commonly used for polymers, elastomers, and rubbers to determine their durability and flexibility. This scale helps you assess the suitability of materials for various applications, ensuring optimal performance in your projects. Discover more about how Shore hardness impacts material selection by reading the full article.

Table of Comparison

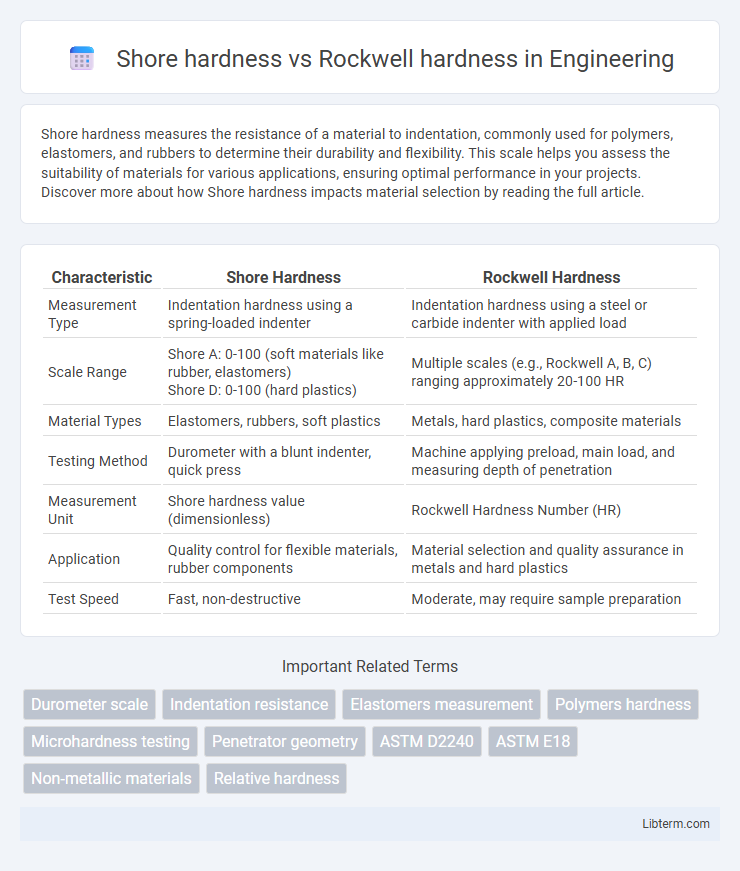

| Characteristic | Shore Hardness | Rockwell Hardness |

|---|---|---|

| Measurement Type | Indentation hardness using a spring-loaded indenter | Indentation hardness using a steel or carbide indenter with applied load |

| Scale Range | Shore A: 0-100 (soft materials like rubber, elastomers) Shore D: 0-100 (hard plastics) |

Multiple scales (e.g., Rockwell A, B, C) ranging approximately 20-100 HR |

| Material Types | Elastomers, rubbers, soft plastics | Metals, hard plastics, composite materials |

| Testing Method | Durometer with a blunt indenter, quick press | Machine applying preload, main load, and measuring depth of penetration |

| Measurement Unit | Shore hardness value (dimensionless) | Rockwell Hardness Number (HR) |

| Application | Quality control for flexible materials, rubber components | Material selection and quality assurance in metals and hard plastics |

| Test Speed | Fast, non-destructive | Moderate, may require sample preparation |

Introduction to Hardness Testing

Hardness testing measures a material's resistance to deformation, with Shore hardness and Rockwell hardness being prominent scales. Shore hardness is commonly used for elastomers and polymers, utilizing a durometer to gauge indentation depth. Rockwell hardness focuses on metals and alloys by assessing the depth of penetration under a specific load using a standardized indenter.

Understanding Shore Hardness

Shore hardness measures the resistance of elastomers and polymers to indentation, using a durometer scale ranging from Shore A to Shore D depending on material flexibility. It evaluates surface hardness by pressing a standardized indenter into the material and recording the depth of the indentation, making it ideal for softer materials like rubber and plastics. Unlike Rockwell hardness, which tests metals under higher loads and deeper indentations, Shore hardness provides quick, non-destructive testing specifically suited for materials with lower modulus of elasticity.

Overview of Rockwell Hardness

Rockwell hardness measures a material's resistance to indentation using a specific load and a hardened steel or carbide indenter, providing precise and repeatable results ideal for metals and harder plastics. The Rockwell hardness scale includes multiple scales such as A, B, and C, each designed for different materials and indentation depths, allowing versatile application across industries. This method is widely used in quality control and material testing to evaluate tensile strength, wear resistance, and overall durability.

Key Differences Between Shore and Rockwell Hardness

Shore hardness measures the resistance of polymeric materials to indentation using a spring-loaded indenter on scales such as Shore A and D, primarily for softer materials like rubber and plastics. Rockwell hardness evaluates the depth of penetration of an indenter under a major load, using various scales (e.g., Rockwell B, C) suited for metals and harder materials. The key differences lie in the material types tested, the indenter design, and the load applied, with Shore hardness focusing on surface resilience of softer materials and Rockwell hardness quantifying deeper penetration resistance in harder substances.

Materials Suitable for Each Hardness Scale

Shore hardness is primarily used for measuring the hardness of polymers, elastomers, and rubbers, providing valuable data on their flexibility and resistance to indentation. Rockwell hardness, on the other hand, is suitable for metals and alloys, offering precise quantification of their resistance to permanent deformation under applied forces. Selecting the appropriate hardness scale depends on the material's properties and the specific application requirements.

Testing Methods: Shore vs Rockwell

Shore hardness testing measures the resistance of a material to indentation using a durometer with specific indenters like Shore A or Shore D scales, ideal for elastomers and softer plastics. Rockwell hardness testing evaluates a material's hardness by measuring the depth of penetration under a fixed load, commonly used for metals and hard plastics, with scales like Rockwell B and C. Both methods provide critical data but differ in equipment, load application, and material suitability, defining their optimal use cases in quality control and material selection.

Applications of Shore Hardness in Industry

Shore hardness measures the resistance of polymeric materials like rubber and plastics to indentation, making it essential in industries such as automotive for tire and seal testing, and manufacturing for flexible product quality control. Its non-destructive testing capability allows precise evaluation of material properties for consumer goods, medical devices, and footwear, ensuring durability and performance standards. Unlike Rockwell hardness, which is suited for metals, Shore hardness provides critical data for elastomers and softer materials, driving innovation in product design and material selection.

Applications of Rockwell Hardness in Industry

Rockwell hardness testing is extensively utilized in manufacturing industries for evaluating the strength and durability of metals, especially steel and alloys used in automotive, aerospace, and construction sectors. Its ability to provide rapid, precise measurements of material resistance to indentation makes it ideal for quality control and material selection processes. The Rockwell scale's versatility in testing various thicknesses and types of metals enhances its application in ensuring product reliability and performance in industrial settings.

Factors Affecting Hardness Test Results

Material composition and surface condition significantly influence both Shore hardness and Rockwell hardness test results, with factors like temperature and operator technique also causing variability. Shore hardness is often affected by the sample's elasticity and thickness, while Rockwell hardness is sensitive to indentation depth and load application consistency. Calibration of testing equipment and environmental stability further ensure accurate and repeatable hardness measurements.

Choosing the Right Hardness Test for Your Material

Selecting the appropriate hardness test depends on the material's properties and application requirements; Shore hardness is ideal for polymers, elastomers, and softer materials due to its use of a durometer to measure indentation resistance. Rockwell hardness suits metals and hard plastics, providing precise depth measurements with varying scales for different material strengths. Understanding the interaction between material type and testing method ensures accurate characterization and optimal performance evaluations.

Shore hardness Infographic

libterm.com

libterm.com