Push fit connections offer a quick and reliable solution for joining pipes without the need for soldering or special tools. These fittings create a watertight seal, making them ideal for plumbing applications where speed and ease of installation are essential. Discover more about how push fit technology can simplify your next project by reading the full article.

Table of Comparison

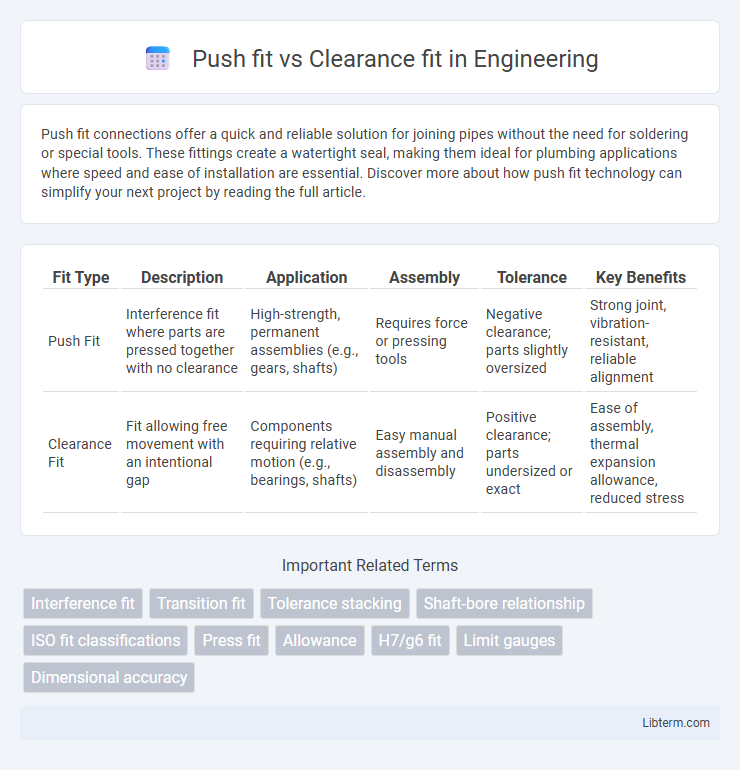

| Fit Type | Description | Application | Assembly | Tolerance | Key Benefits |

|---|---|---|---|---|---|

| Push Fit | Interference fit where parts are pressed together with no clearance | High-strength, permanent assemblies (e.g., gears, shafts) | Requires force or pressing tools | Negative clearance; parts slightly oversized | Strong joint, vibration-resistant, reliable alignment |

| Clearance Fit | Fit allowing free movement with an intentional gap | Components requiring relative motion (e.g., bearings, shafts) | Easy manual assembly and disassembly | Positive clearance; parts undersized or exact | Ease of assembly, thermal expansion allowance, reduced stress |

Understanding Push Fit and Clearance Fit

Push fit, also known as interference fit, involves components designed to be slightly larger than the mating hole, creating a tight, secure joint upon assembly without additional fasteners. Clearance fit provides a deliberate gap between parts, ensuring free movement or easy assembly and disassembly, commonly used in applications requiring rotational or sliding motion. Understanding these fits is crucial in mechanical design to balance assembly ease, strength, and functional performance depending on the application's tolerance requirements.

Key Differences Between Push Fit and Clearance Fit

Push fit involves assembling parts by applying force to create an interference fit, ensuring a tight, secure connection without movement. Clearance fit allows parts to slide or move freely within a specified gap, providing ease of assembly and disassembly. Key differences include the interference vs. gap allowance, resulting in varied mechanical performance and application suitability.

When to Use Push Fit in Mechanical Assemblies

Push fit is ideal for mechanical assemblies requiring a secure, interference fit without additional fasteners, often used in applications like bearing installations or dowel pins where precise alignment and easy assembly are crucial. This method ensures components stay firmly in place under moderate loads and vibrations while allowing for disassembly if necessary. Push fit is preferred when high dimensional accuracy of mating parts is achievable and a tight, reliable joint is needed without excessive force or risk of damage.

Applications Best Suited for Clearance Fit

Clearance fit is best suited for applications requiring easy assembly and disassembly, such as keys in keyways, bushings, and bearing housings where relative motion or thermal expansion occurs. This fit provides adequate space between parts to prevent binding and allows for lubrication flow, ideal for accommodating manufacturing tolerances and operational conditions. Machinery components like sliding shafts, gears, and couplings benefit from clearance fits due to their need for smooth movement and maintenance access.

Advantages of Push Fit Connections

Push fit connections offer the advantage of quick and easy assembly without the need for additional tools or fasteners, significantly reducing installation time and labor costs. Their design ensures a secure and precise fit, providing excellent resistance to vibration and axial loads, enhancing the reliability of mechanical joints. Furthermore, push fit components facilitate disassembly and maintenance, enabling efficient part replacement without damaging the connected elements.

Benefits of Clearance Fit Design

Clearance fit design offers enhanced ease of assembly by allowing components to slide or move freely without interference, reducing manufacturing complexity and time. This fit accommodates manufacturing tolerances and thermal expansion, minimizing the risk of stress, deformation, or damage during operation. Improved serviceability and maintenance accessibility are achieved due to the ability to disassemble parts without specialized tools or techniques.

Common Materials for Push and Clearance Fits

Push fit commonly uses materials like aluminum, brass, and plastic due to their slight elasticity and ability to deform for a tight assembly, while steel is often avoided to prevent damage or excessive force. Clearance fit typically employs harder materials such as hardened steel, stainless steel, and cast iron, allowing space for thermal expansion and lubrication without interference. Materials selected for each fit type optimize performance by balancing tolerance, strength, and ease of assembly in mechanical engineering applications.

Dimensional Tolerances: Push Fit vs Clearance Fit

Dimensional tolerances in push fit applications are typically tighter to ensure an interference fit, meaning the shaft diameter slightly exceeds the hole diameter, creating a secure and immovable joint. Clearance fit tolerances provide intentional space between mating parts, allowing free movement or easy assembly with shaft diameters slightly smaller than hole diameters. These precise tolerance ranges directly affect the performance, assembly method, and functional requirements of mechanical components.

Factors Affecting Fit Selection in Engineering

Factors affecting fit selection in engineering include material properties, load conditions, and required tolerance levels. Push fit requires precise interference tolerance for secure assembly, typically used with softer materials to avoid damage, while clearance fit allows slight gaps promoting easy movement or assembly under thermal expansion. Environmental conditions such as temperature, corrosion, and vibration also influence whether a push fit or clearance fit is most suitable for a given application.

Choosing the Right Fit for Your Application

Selecting the appropriate fit between push fit and clearance fit depends on the application's load, tolerance, and assembly requirements. Push fit offers a tight, interference fit suitable for static or heavy-load assemblies requiring minimal movement and secure positioning. Clearance fit allows easier assembly with a slight gap, ideal for applications needing free movement or thermal expansion without compromising alignment.

Push fit Infographic

libterm.com

libterm.com