DC motors convert direct current electrical energy into mechanical motion through the interaction of magnetic fields and armature windings. Their precise speed control and high starting torque make them ideal for applications ranging from robotics to electric vehicles. Explore the rest of the article to discover how your projects can benefit from the versatile performance of DC motors.

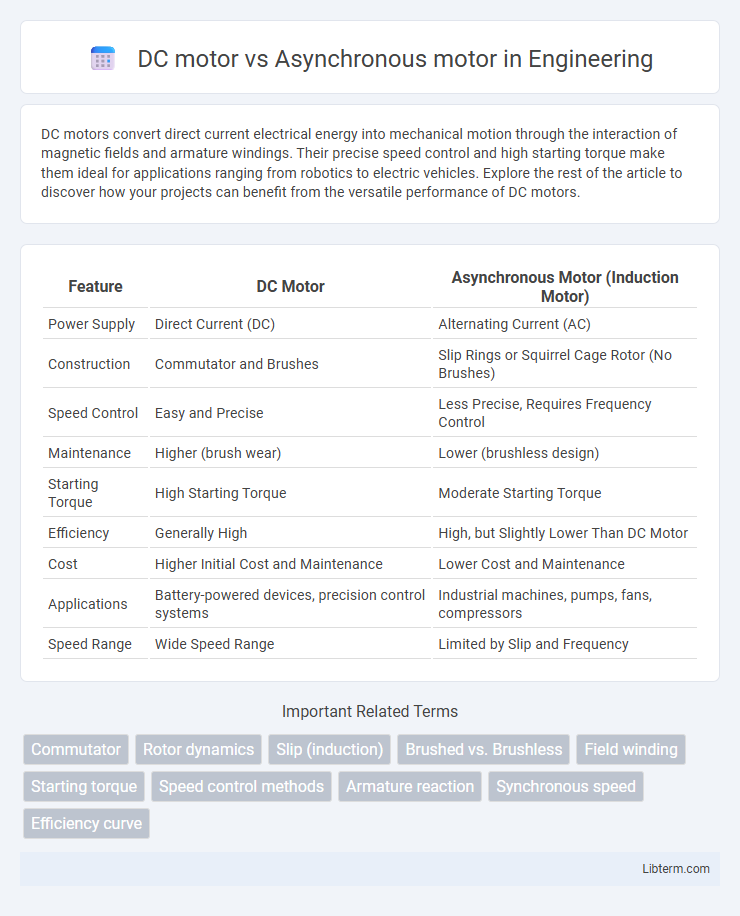

Table of Comparison

| Feature | DC Motor | Asynchronous Motor (Induction Motor) |

|---|---|---|

| Power Supply | Direct Current (DC) | Alternating Current (AC) |

| Construction | Commutator and Brushes | Slip Rings or Squirrel Cage Rotor (No Brushes) |

| Speed Control | Easy and Precise | Less Precise, Requires Frequency Control |

| Maintenance | Higher (brush wear) | Lower (brushless design) |

| Starting Torque | High Starting Torque | Moderate Starting Torque |

| Efficiency | Generally High | High, but Slightly Lower Than DC Motor |

| Cost | Higher Initial Cost and Maintenance | Lower Cost and Maintenance |

| Applications | Battery-powered devices, precision control systems | Industrial machines, pumps, fans, compressors |

| Speed Range | Wide Speed Range | Limited by Slip and Frequency |

Introduction to DC Motors and Asynchronous Motors

DC motors operate using direct current to generate a magnetic field that interacts with the rotor, enabling precise speed control and high starting torque, making them ideal for applications requiring variable speed and immediate response. Asynchronous motors, also known as induction motors, function based on electromagnetic induction where the rotor rotates at a speed slightly less than the synchronous speed of the stator's magnetic field, offering robustness, simplicity, and cost-effectiveness for continuous operation. Both motor types serve distinct industrial and commercial needs, with DC motors favored for controlled motion tasks and asynchronous motors widely used in steady-speed applications like pumps and fans.

Basic Construction and Working Principles

DC motors consist of a stator with permanent magnets or field windings and a rotor with armature windings connected to a commutator, enabling current reversal and continuous torque. Asynchronous motors, also known as induction motors, feature a stator with three-phase windings producing a rotating magnetic field and a squirrel-cage rotor where currents are induced, causing rotor motion without direct electrical connection. The fundamental difference lies in the DC motor's reliance on mechanical commutation for current direction, while asynchronous motors operate through electromagnetic induction between stator and rotor fields.

Key Differences in Operation

DC motors operate using direct current, enabling precise speed control through varying voltage or current, which suits applications requiring adjustable speed and torque. Asynchronous motors, also known as induction motors, run on alternating current and rely on electromagnetic induction to produce rotor rotation, typically offering simpler construction and lower maintenance. The key operational difference lies in the DC motor's ability to provide controlled speed and torque, whereas the asynchronous motor runs at a speed slightly less than the synchronous speed determined by the supply frequency.

Performance and Efficiency Comparison

DC motors offer precise speed control and high starting torque, making them suitable for applications requiring variable speed and load adaptability. Asynchronous motors, also known as induction motors, exhibit rugged construction and lower maintenance with efficiency rates typically ranging from 85% to 95%, ideal for constant speed operations. Performance-wise, DC motors excel in dynamic response and torque control, while asynchronous motors provide better efficiency and reliability in industrial settings.

Control Methods and Flexibility

DC motors offer precise speed and torque control through direct voltage regulation and armature current adjustment, enabling excellent dynamic response and high accuracy in applications like robotics and electric vehicles. Asynchronous motors rely on variable frequency drives (VFDs) for speed control, which provide flexibility but generally result in less precise control and slower response compared to DC motors. The inherent design of DC motors supports simpler and more effective control strategies, whereas asynchronous motors benefit from ruggedness and lower maintenance with advanced electronic control systems to improve flexibility.

Applications and Use Cases

DC motors are widely used in applications requiring precise speed control and high starting torque, such as electric vehicles, robotics, and industrial conveyors. Asynchronous motors, also known as induction motors, dominate in heavy-duty applications like pumps, fans, compressors, and HVAC systems due to their rugged construction and low maintenance. The choice between DC and asynchronous motors depends on the need for variable speed performance versus cost-effective, reliable operation in continuous duty cycles.

Maintenance and Durability

DC motors require more frequent maintenance due to brush and commutator wear, making them less durable than asynchronous motors. Asynchronous motors, also known as induction motors, have a simpler design with no brushes, leading to lower maintenance costs and longer operational life. Their robust construction enables asynchronous motors to withstand harsh operating conditions, enhancing overall durability.

Cost Factors and Economic Considerations

DC motors generally have higher initial costs due to their complex construction and maintenance requirements, including brushes and commutators, which increase operational expenses over time. Asynchronous motors, or induction motors, offer lower upfront costs and reduced maintenance needs because of their simpler, brushless design, making them more economical for long-term industrial applications. Energy efficiency, reliability, and lifespan also favor asynchronous motors, leading to lower total cost of ownership compared to DC motors in most industrial environments.

Energy Consumption and Environmental Impact

DC motors typically consume more energy due to brushes and commutators causing frictional losses, whereas asynchronous motors (induction motors) are generally more energy-efficient with lower maintenance demands. Asynchronous motors operate without brushes, reducing energy losses and environmental hazards associated with brush wear and disposal. Their energy efficiency and longer lifespan contribute to a smaller carbon footprint and reduced environmental impact in industrial applications.

Choosing the Right Motor for Your Needs

Selecting the right motor depends on the specific application requirements such as speed control, torque, and efficiency. DC motors offer precise speed control and high starting torque, making them ideal for applications like electric vehicles and robotics. Asynchronous motors, or induction motors, provide robustness, low maintenance, and cost-effectiveness, suitable for industrial machinery and HVAC systems where variable speed control is less critical.

DC motor Infographic

libterm.com

libterm.com