Conventional materials such as wood, steel, and concrete have been the foundation of construction and manufacturing for centuries due to their reliability and availability. These materials offer proven performance in strength, durability, and cost-effectiveness, making them ideal for a wide range of projects. Explore the rest of this article to understand how conventional materials continue to shape modern design and innovation.

Table of Comparison

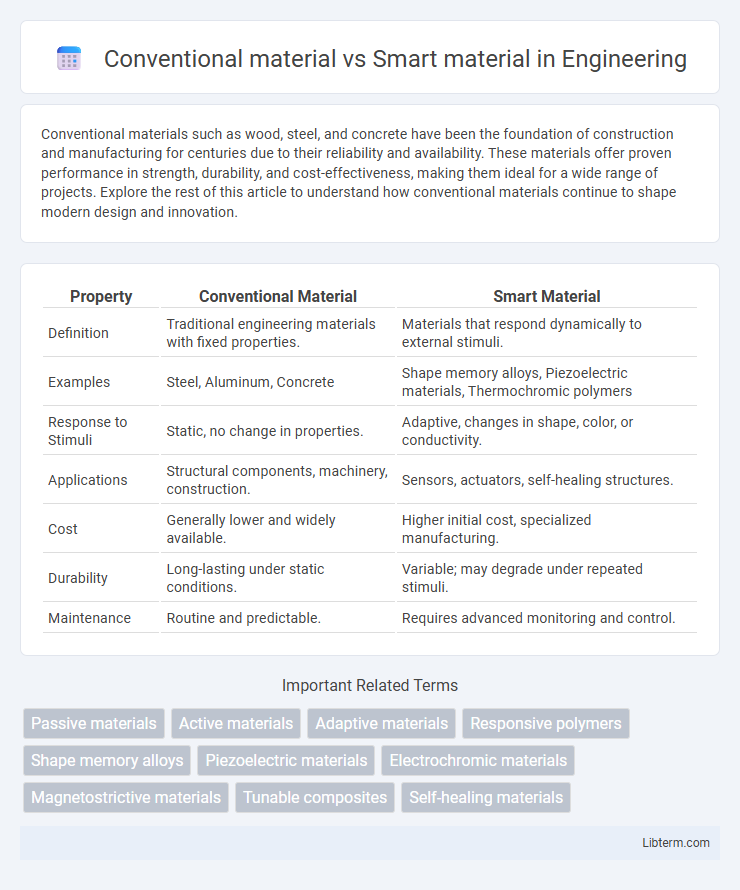

| Property | Conventional Material | Smart Material |

|---|---|---|

| Definition | Traditional engineering materials with fixed properties. | Materials that respond dynamically to external stimuli. |

| Examples | Steel, Aluminum, Concrete | Shape memory alloys, Piezoelectric materials, Thermochromic polymers |

| Response to Stimuli | Static, no change in properties. | Adaptive, changes in shape, color, or conductivity. |

| Applications | Structural components, machinery, construction. | Sensors, actuators, self-healing structures. |

| Cost | Generally lower and widely available. | Higher initial cost, specialized manufacturing. |

| Durability | Long-lasting under static conditions. | Variable; may degrade under repeated stimuli. |

| Maintenance | Routine and predictable. | Requires advanced monitoring and control. |

Introduction to Conventional and Smart Materials

Conventional materials such as metals, ceramics, and polymers possess fixed physical properties that remain unchanged under normal conditions, providing structural stability and reliability in traditional engineering applications. Smart materials, including shape memory alloys, piezoelectric materials, and electrochromic polymers, actively respond to external stimuli like temperature, stress, or electric fields by altering their properties or behavior. The integration of smart materials in advanced technology enables adaptive, self-healing, and energy-efficient systems beyond the capabilities of conventional materials.

Defining Conventional Materials

Conventional materials, including metals, ceramics, and polymers, possess fixed properties that do not change in response to environmental stimuli such as temperature, pressure, or electromagnetic fields. These materials rely on well-established physical and chemical characteristics, making them predictable and widely used in traditional engineering applications. Unlike smart materials, conventional materials lack the capability to adapt, sense, or self-heal, limiting their functionality in dynamic or complex environments.

Understanding Smart Materials

Smart materials exhibit the ability to respond dynamically to environmental stimuli such as temperature, stress, moisture, or electric and magnetic fields, unlike conventional materials that maintain static properties. These materials include piezoelectric, shape memory alloys, and electrochromic substances, enabling applications in adaptive structures, sensors, and actuators. Understanding smart materials involves studying their inherent self-sensing and self-actuating capabilities, which allow for enhanced functionality and improved performance in engineering and biomedical fields.

Historical Evolution of Material Technologies

Conventional materials, such as metals, ceramics, and polymers, have been fundamental since ancient civilizations, enabling the construction of tools, structures, and machinery through well-established properties and manufacturing techniques. The historical evolution of material technologies advanced significantly during the Industrial Revolution with the development of steel production and synthetic polymers, paving the way for higher strength, durability, and mass production capabilities. Smart materials emerged in the late 20th century, incorporating responsive properties like shape memory alloys, piezoelectric materials, and electrochromic polymers, reflecting a paradigm shift towards adaptive, multifunctional materials in engineering and technology.

Key Properties: Conventional vs. Smart Materials

Conventional materials like steel and wood exhibit fixed properties such as density, strength, and thermal conductivity, which remain constant under typical environmental conditions. Smart materials, including shape memory alloys and piezoelectric ceramics, possess adaptive properties that respond dynamically to external stimuli like temperature, stress, or electric fields. These responsive behaviors enable smart materials to self-heal, change shape, or alter stiffness, offering advanced functionality absent in traditional materials.

Functional Advantages of Smart Materials

Smart materials offer functional advantages over conventional materials through their ability to respond dynamically to environmental stimuli such as temperature, pressure, and electromagnetic fields. These materials enable adaptive performance, including self-healing, shape memory, and energy harvesting, which conventional materials typically lack. The integration of smart materials in engineering and technology enhances efficiency, durability, and functionality in applications ranging from aerospace to biomedical devices.

Applications in Industry and Technology

Conventional materials such as steel and aluminum remain fundamental in construction and automotive industries due to their durability and cost-effectiveness. Smart materials, including shape-memory alloys and piezoelectric sensors, increasingly revolutionize aerospace engineering and robotics by enabling adaptive and responsive systems. The integration of smart materials enhances energy efficiency, self-repair capabilities, and real-time monitoring in advanced technological applications.

Environmental Impact and Sustainability

Conventional materials such as metals, plastics, and concrete often have high environmental footprints due to resource extraction, energy-intensive manufacturing processes, and limited recyclability. Smart materials, including shape memory alloys, self-healing polymers, and piezoelectric materials, contribute to sustainability by enhancing energy efficiency, reducing waste through longer lifespans, and enabling adaptive recycling technologies. The integration of smart materials in construction and manufacturing promotes reduced carbon emissions and supports circular economy principles by minimizing raw material consumption and enhancing product lifecycle management.

Challenges and Limitations

Conventional materials often face limitations such as low adaptability, inability to self-repair, and restricted functionality under dynamic conditions, hindering their performance in advanced applications. Smart materials, while offering enhanced responsiveness and multifunctionality, encounter challenges including high production costs, complex fabrication processes, and stability issues under prolonged environmental exposure. The integration of smart materials in mainstream industries is also limited by scalability concerns and the need for specialized control systems.

Future Trends in Material Science

Future trends in material science emphasize the transition from conventional materials such as steel and aluminum to smart materials like shape-memory alloys, piezoelectric materials, and self-healing polymers that respond adaptively to environmental changes. Advancements in nanotechnology and bio-inspired materials enable smart systems with enhanced durability, energy efficiency, and multifunctionality. Integration of artificial intelligence in material design accelerates the development of smart materials tailored for applications in aerospace, biomedical devices, and sustainable infrastructure.

Conventional material Infographic

libterm.com

libterm.com