Gas cycle refrigeration systems utilize the compression and expansion of a refrigerant gas to absorb and remove heat from a designated space, providing efficient cooling without the need for phase change. These systems often employ gases like air or helium, making them suitable for specialized applications where traditional vapor-compression refrigeration is impractical. Discover how gas cycle refrigeration can optimize your cooling needs by exploring its components and operational principles in the rest of this article.

Table of Comparison

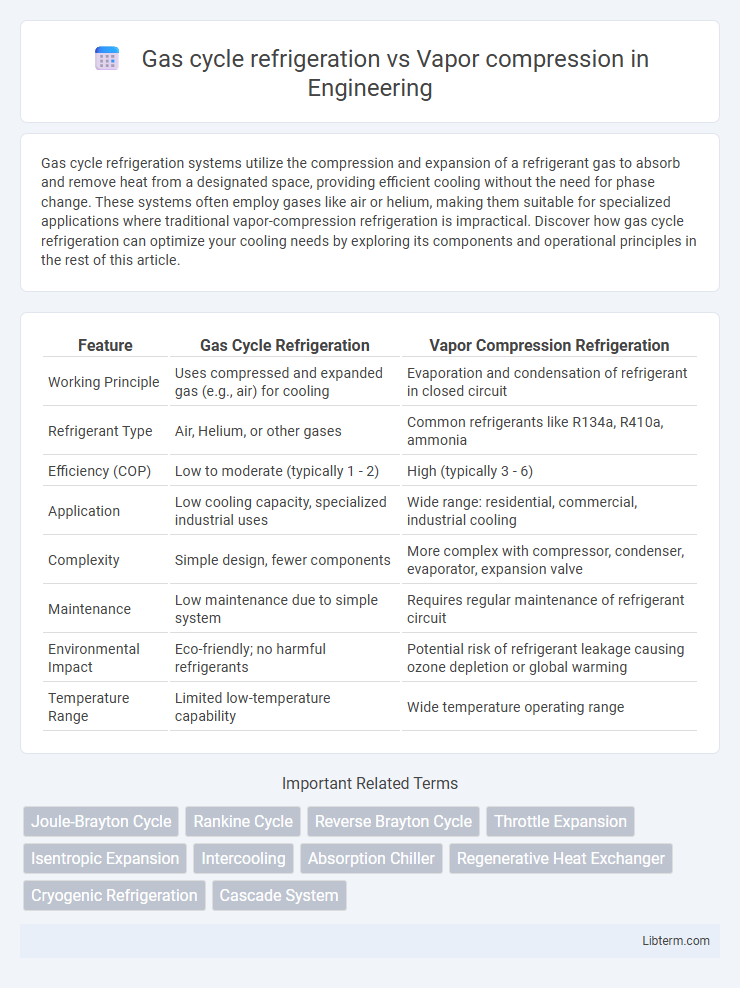

| Feature | Gas Cycle Refrigeration | Vapor Compression Refrigeration |

|---|---|---|

| Working Principle | Uses compressed and expanded gas (e.g., air) for cooling | Evaporation and condensation of refrigerant in closed circuit |

| Refrigerant Type | Air, Helium, or other gases | Common refrigerants like R134a, R410a, ammonia |

| Efficiency (COP) | Low to moderate (typically 1 - 2) | High (typically 3 - 6) |

| Application | Low cooling capacity, specialized industrial uses | Wide range: residential, commercial, industrial cooling |

| Complexity | Simple design, fewer components | More complex with compressor, condenser, evaporator, expansion valve |

| Maintenance | Low maintenance due to simple system | Requires regular maintenance of refrigerant circuit |

| Environmental Impact | Eco-friendly; no harmful refrigerants | Potential risk of refrigerant leakage causing ozone depletion or global warming |

| Temperature Range | Limited low-temperature capability | Wide temperature operating range |

Introduction to Gas Cycle and Vapor Compression Refrigeration

Gas cycle refrigeration operates on the reversed Brayton or Joule cycle, utilizing compressed gas such as air to absorb heat during expansion, making it suitable for low-temperature applications and environments requiring non-toxic refrigerants. Vapor compression refrigeration relies on the phase change of a refrigerant, where the refrigerant compresses, condenses, expands, and evaporates to transfer heat efficiently in residential, commercial, and industrial cooling. Key differences include the working fluid states--gas for gas cycle and vapor-liquid for vapor compression--and cycle efficiency, with vapor compression systems generally providing higher Coefficient of Performance (COP) for common refrigeration needs.

Basic Principles of Gas Cycle Refrigeration

Gas cycle refrigeration operates on the principle of compressing and expanding a working gas, typically air, to absorb and reject heat through pressure and temperature changes without phase changes. The process involves isentropic compression raising the gas temperature, followed by heat rejection at constant pressure, expansion cooling the gas below ambient temperature, and heat absorption to complete the cycle. Unlike vapor compression systems that rely on phase changes of refrigerants, gas cycle refrigeration is driven by gas thermodynamics, enabling simpler and environmentally friendly cooling solutions.

Fundamentals of Vapor Compression Refrigeration

Vapor compression refrigeration operates on the principles of compression, condensation, expansion, and evaporation, utilizing a refrigerant that changes phase to absorb and remove heat efficiently. The cycle relies on a compressor to increase refrigerant pressure, a condenser to dissipate heat, an expansion valve to reduce pressure, and an evaporator to absorb heat from the environment. Compared to gas cycle refrigeration, vapor compression offers higher efficiency and is widely used in air conditioning and refrigeration systems due to its effective thermodynamic properties.

Key Components in Each Refrigeration System

Gas cycle refrigeration primarily consists of components such as the compressor, heater, expander, and cooler, which work together to cycle the refrigerant gas through compression, heating, expansion, and cooling phases. Vapor compression systems rely on a compressor, condenser, expansion valve, and evaporator to facilitate the phase change of the refrigerant from vapor to liquid and back, enabling efficient heat transfer. The key difference lies in the gas cycle using a gaseous refrigerant throughout the cycle, whereas vapor compression involves phase changes, impacting system design and efficiency.

Thermodynamic Comparison: Gas Cycle vs Vapor Compression

Gas cycle refrigeration systems operate on the Brayton or reversed Brayton cycle, utilizing air or other gases as the working fluid, whereas vapor compression refrigeration relies on the vapor-liquid phase change of refrigerants within a Rankine cycle framework. Thermodynamically, vapor compression cycles achieve higher coefficients of performance (COP) due to the latent heat absorption during phase change, while gas cycle systems have lower COP but benefit from simpler components and environmentally benign working fluids with no risk of refrigerant leakage. The isentropic efficiency of compressors and expanders heavily influences gas cycle performance, whereas vapor compression depends on compressor efficiency and heat exchanger effectiveness to optimize energy consumption.

Efficiency and Performance Metrics

Gas cycle refrigeration systems generally exhibit lower coefficients of performance (COP) compared to vapor compression systems due to higher work input and thermodynamic irreversibilities. Vapor compression cycles, leveraging phase change of refrigerants, achieve higher energy efficiency and superior cooling capacity per unit of work. Performance metrics such as COP and specific cooling power distinctly favor vapor compression, making it the preferred choice for commercial and residential cooling applications.

Environmental Impact and Refrigerant Use

Gas cycle refrigeration systems use air or inert gases as refrigerants, eliminating the risk of ozone depletion and minimizing greenhouse gas emissions, whereas vapor compression systems typically rely on hydrofluorocarbons (HFCs) that can contribute to global warming if leaked. The absence of harmful refrigerants in gas cycle systems offers a significant environmental advantage, reducing the potential for refrigerant-related climate impact. Vapor compression refrigeration often requires careful management and containment of HFCs to mitigate environmental harm, highlighting the gas cycle's eco-friendly profile.

Common Applications and Industry Uses

Gas cycle refrigeration is commonly used in applications requiring extremely low temperatures such as liquefying gases and cryogenics, benefiting industries like aerospace and chemical processing. Vapor compression systems dominate commercial and residential cooling, including air conditioning and refrigeration sectors due to their efficiency and adaptability. Both cycles serve essential roles, with gas cycle favored for specialized industrial cooling and vapor compression preferred for widespread HVAC and refrigeration needs.

Advantages and Disadvantages of Each System

Gas cycle refrigeration offers advantages such as operation at very low temperatures and the ability to use inert gases, making it suitable for specialized industrial applications. However, its efficiency is generally lower compared to vapor compression systems, and the complexity of components results in higher initial costs and maintenance requirements. Vapor compression refrigeration provides higher efficiency, widespread availability, and cost-effective performance for typical cooling needs, but it relies on refrigerants that may pose environmental risks and is less effective at extremely low temperatures.

Future Trends in Refrigeration Technologies

Gas cycle refrigeration shows promise for future trends due to its eco-friendly refrigerants and potential for high efficiency at low temperatures, making it suitable for industrial applications and cryogenics. Vapor compression systems continue to dominate the market, driven by advancements in variable-speed compressors, magnetic refrigeration integration, and natural refrigerants like propane and CO2 to reduce greenhouse gas emissions. Emerging technologies emphasize energy efficiency, environmental impact reduction, and system integration with renewable energy sources to meet stricter global regulations.

Gas cycle refrigeration Infographic

libterm.com

libterm.com