Axial flow refers to the movement of fluid or gas parallel to the axis of a machine, such as a turbine or a compressor, enabling efficient energy transfer and continuous flow. This type of flow is commonly utilized in various industrial applications, including jet engines and ventilation systems, due to its high flow capacity and aerodynamic efficiency. Discover how axial flow technology optimizes performance and impacts your engineering projects by reading the full article.

Table of Comparison

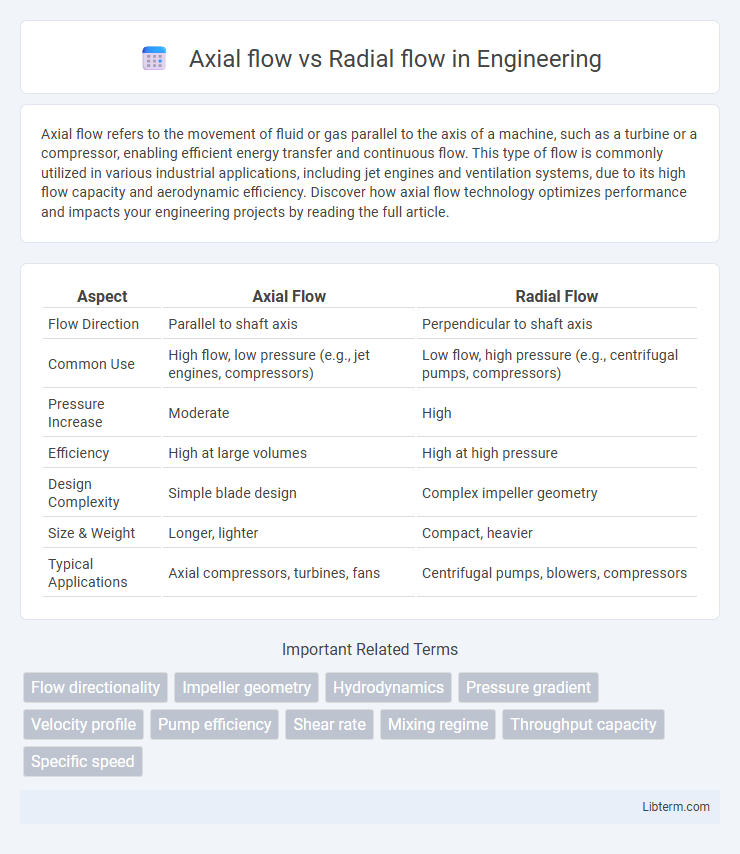

| Aspect | Axial Flow | Radial Flow |

|---|---|---|

| Flow Direction | Parallel to shaft axis | Perpendicular to shaft axis |

| Common Use | High flow, low pressure (e.g., jet engines, compressors) | Low flow, high pressure (e.g., centrifugal pumps, compressors) |

| Pressure Increase | Moderate | High |

| Efficiency | High at large volumes | High at high pressure |

| Design Complexity | Simple blade design | Complex impeller geometry |

| Size & Weight | Longer, lighter | Compact, heavier |

| Typical Applications | Axial compressors, turbines, fans | Centrifugal pumps, blowers, compressors |

Introduction to Axial and Radial Flow

Axial flow compressors move air parallel to the axis of rotation, enabling higher flow rates and suitability for high-speed applications like jet engines and gas turbines. Radial flow compressors direct air perpendicularly outward from the shaft center, providing higher pressure ratios per stage and compact design optimal for small-scale turbines and turbochargers. Both types play crucial roles in aerodynamics and mechanical engineering, with axial flow favored for efficiency and radial flow for pressure generation.

Definition and Principle of Axial Flow

Axial flow refers to the movement of fluid parallel to the axis of rotation, typically seen in axial flow compressors and fans where air or gas flows straight through the machine. The principle of axial flow involves the continuous acceleration of fluid particles along the axis by rotating blades, resulting in increased pressure and velocity without significant changes in flow direction. In contrast, radial flow involves fluid moving perpendicular to the axis, flowing outward or inward from the center, commonly used in centrifugal pumps and compressors.

Definition and Principle of Radial Flow

Radial flow refers to a fluid movement pattern where the fluid flows perpendicular to the axis of rotation, moving from the center outward or vice versa, commonly found in pumps and compressors. The principle of radial flow relies on centrifugal force to increase fluid velocity and pressure as it moves through the impeller, converting kinetic energy into pressure energy efficiently. In comparison, axial flow involves fluid moving parallel to the axis, typically used for high flow rates at low pressure increases.

Key Differences Between Axial and Radial Flow

Axial flow pumps move fluid parallel to the shaft, enabling high flow rates with low pressure increase, whereas radial flow pumps move fluid perpendicular to the shaft, producing higher pressure with lower flow rates. Axial flow designs are typically used in applications requiring large volumes of fluid, such as irrigation or flood control, while radial flow pumps are suited for high-pressure tasks like water supply systems and chemical processing. The efficiency of axial flow pumps decreases at higher pressures, while radial flow pumps maintain better efficiency across a wider range of pressures and flow rates.

Design and Construction Aspects

Axial flow compressors feature blades that rotate parallel to the flow direction, enabling high flow rates with moderate pressure increases and a compact design ideal for jet engines. Radial flow compressors, on the other hand, direct airflow outward perpendicular to the axis, achieving higher pressure ratios per stage through centrifugal force but requiring larger housings and more complex diffusers. The construction of axial flow compressors involves multiple stages with closely spaced rotor and stator blades, whereas radial flow compressors use a single impeller and volute casing, influencing maintenance and aerodynamic efficiency.

Performance Characteristics Comparison

Axial flow compressors provide higher flow rates and efficiency at lower pressure ratios, making them ideal for applications requiring large volumes of air with moderate compression. Radial flow compressors achieve higher pressure ratios per stage but typically handle lower flow rates, offering compact design advantages and better performance in systems with limited space. The choice between axial and radial flow compressors depends on balancing flow capacity, pressure requirements, and spatial constraints for optimal system performance.

Common Applications of Axial Flow Systems

Axial flow systems are commonly used in applications requiring high flow rates with low pressure rise, such as ventilation in HVAC systems, cooling towers, and aircraft jet engines. These fans and compressors efficiently move large volumes of air or gas along the axis of rotation, making them ideal for industrial processes and power plants. Their design enables effective airflow in turbines and axial compressors where space and aerodynamic performance are critical.

Common Applications of Radial Flow Systems

Radial flow systems are widely used in applications requiring moderate pressure and flow rates, such as centrifugal pumps for water supply, HVAC systems, and chemical processing industries. Their compact design and efficiency at handling high-pressure differentials make them ideal for boiler feedwater pumps and fuel injection in automotive engines. Industrial compressors and wastewater treatment plants also frequently utilize radial flow technology due to its robustness and reliability in demanding operating conditions.

Advantages and Limitations of Each Flow Type

Axial flow compressors offer high flow rates with relatively compact design, making them ideal for applications requiring efficient, continuous airflow such as jet engines; however, they tend to have complex blade geometry and can suffer from stall and surge issues at off-design conditions. Radial flow compressors provide higher pressure ratios per stage and robustness in handling varying flow rates, which benefits smaller machinery like turbochargers, but they generally incur higher aerodynamic losses and lower efficiency at high flow volumes. Understanding these trade-offs helps optimize compressor selection based on pressure requirements, flow capacity, and mechanical constraints.

Choosing the Right Flow Type for Your Needs

Selecting between axial flow and radial flow pumps depends on the specific application requirements such as flow rate, pressure, and space constraints. Axial flow pumps are ideal for high flow rates with low to medium pressure, commonly used in irrigation and flood control, while radial flow pumps provide higher pressure at lower flow rates, making them suitable for industrial processes and boiler feed systems. Understanding these performance characteristics ensures efficient operation and energy savings tailored to your system's demands.

Axial flow Infographic

libterm.com

libterm.com