Friction stir welding (FSW) is an innovative solid-state joining process that uses a rotating tool to generate frictional heat, softening the materials without melting them. This technique ensures strong, defect-free welds with minimal distortion, making it ideal for joining aluminum alloys and other difficult-to-weld metals. Discover how friction stir welding can enhance Your manufacturing processes by reading the full article.

Table of Comparison

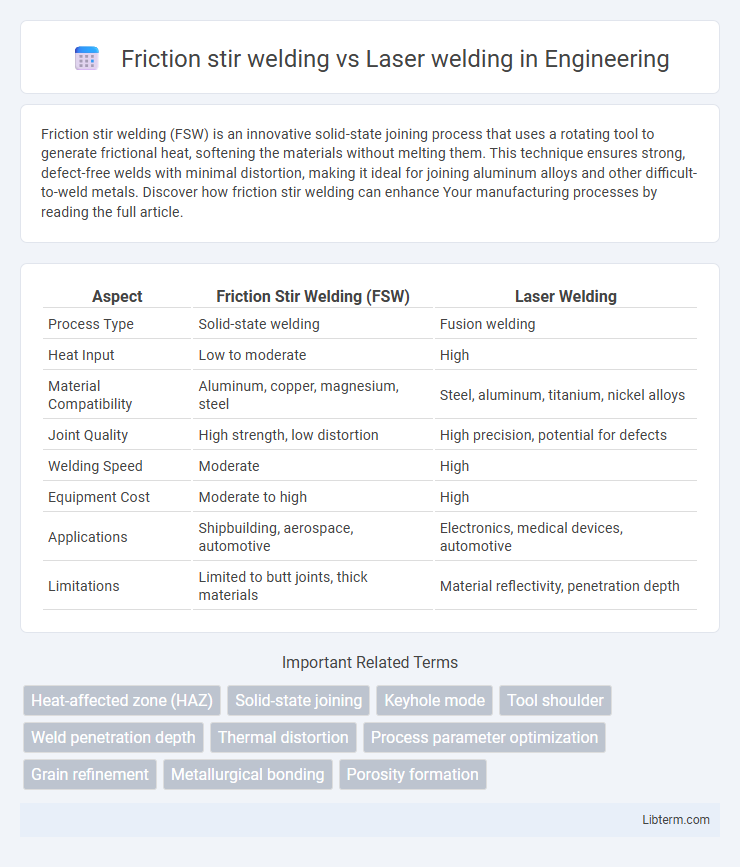

| Aspect | Friction Stir Welding (FSW) | Laser Welding |

|---|---|---|

| Process Type | Solid-state welding | Fusion welding |

| Heat Input | Low to moderate | High |

| Material Compatibility | Aluminum, copper, magnesium, steel | Steel, aluminum, titanium, nickel alloys |

| Joint Quality | High strength, low distortion | High precision, potential for defects |

| Welding Speed | Moderate | High |

| Equipment Cost | Moderate to high | High |

| Applications | Shipbuilding, aerospace, automotive | Electronics, medical devices, automotive |

| Limitations | Limited to butt joints, thick materials | Material reflectivity, penetration depth |

Introduction to Friction Stir Welding and Laser Welding

Friction stir welding (FSW) is a solid-state joining process that uses a non-consumable rotating tool to generate frictional heat, plasticize materials, and create a strong, defect-free weld typically employed in aluminum alloys and aerospace industries. Laser welding utilizes a high-energy laser beam to melt and fuse materials with precision, enabling high-speed, narrow, and deep welds, commonly used in automotive, electronics, and medical device manufacturing. Both processes offer unique advantages in terms of heat input, weld quality, and material compatibility, driving their selection based on specific industrial application requirements.

Principles of Friction Stir Welding

Friction stir welding (FSW) operates by generating heat through the mechanical friction between a rotating tool and the workpieces, softening the material without melting it. This solid-state joining process produces a high-strength weld with minimal distortion, making it ideal for aluminum alloys and other metals sensitive to melting. Unlike laser welding, which uses concentrated laser beams to melt and fuse materials, FSW ensures enhanced mechanical properties by maintaining the base material's microstructure integrity.

Fundamentals of Laser Welding

Laser welding utilizes a highly concentrated laser beam to melt and fuse materials with precise heat input, enabling deep penetration and narrow weld seams. The process relies on the absorption of laser energy by the metal surface, producing a keyhole that ensures strong, high-quality joints with minimal distortion. Compared to friction stir welding, laser welding offers faster processing speeds and greater flexibility for welding thin sheets and complex geometries.

Key Differences Between Friction Stir Welding and Laser Welding

Friction stir welding (FSW) utilizes a rotating tool to mechanically join materials through solid-state plastic deformation, producing strong, defect-free joints mainly in aluminum alloys. Laser welding leverages a concentrated laser beam to melt and fuse materials, offering high precision, fast processing speeds, and suitability for thinner or complex geometries in metals like stainless steel and titanium. Key differences include FSW's reliance on mechanical stirring for solid-state joining with minimal distortion, while laser welding involves localized melting and rapid solidification, affecting microstructure and mechanical properties distinctly.

Material Compatibility and Applications

Friction stir welding (FSW) excels in joining aluminum alloys, magnesium, and copper with excellent mechanical properties and minimal distortion, making it ideal for aerospace and automotive components. Laser welding offers superior precision and speed, effectively joining dissimilar materials such as stainless steel and titanium, commonly used in medical devices and electronics. Both techniques support high-strength joints but differ significantly in material compatibility and specific industrial applications.

Joint Quality and Mechanical Properties

Friction stir welding produces high-quality joints with minimal distortion and excellent mechanical properties due to its solid-state process, resulting in enhanced weld strength and fatigue resistance. Laser welding offers precise control and deep penetration, yielding joints with narrow heat-affected zones but may be more prone to defects like porosity or cracking under improper parameter settings. Both methods optimize joint integrity, yet friction stir welding typically provides superior toughness and reduced residual stress in aluminum and other alloys compared to laser welding.

Process Efficiency and Speed Comparison

Friction stir welding (FSW) offers high process efficiency for joining aluminum alloys with minimal distortion, operating at relatively low speeds of 30 to 300 mm/min, which suits thick materials and complex joints. Laser welding enables significantly higher welding speeds, often exceeding 1000 mm/min, making it ideal for thin materials and high-throughput applications, but it may require precise joint fit-up and greater post-weld finishing. While FSW provides excellent defect control and energy efficiency for heavy-duty fabrication, laser welding excels in speed and automation, influencing their selection based on production volume and material thickness.

Equipment Requirements and Cost Analysis

Friction stir welding requires a robust mechanical setup with a rotating tool, precision control systems, and a stable clamping mechanism, making initial equipment costs substantial but offset by low consumable expenses. Laser welding involves high-power laser sources, advanced optics, and protective enclosures, resulting in significantly higher capital investment and maintenance costs. Overall, friction stir welding is cost-effective for thick or large components, whereas laser welding suits high-speed, precise applications despite its higher equipment and operational expenses.

Safety Considerations and Operational Challenges

Friction stir welding (FSW) offers a safer operation by eliminating harmful fumes and reducing the risk of fire compared to laser welding, which involves high-intensity beams that require stringent eye and skin protection protocols. Operational challenges in FSW include precise control of tool parameters and the need for robust clamping systems to manage the intense mechanical forces, while laser welding demands high-quality beam alignment, surface preparation, and management of thermal distortion. Both methods require specialized training, but laser welding poses heightened risks due to the exposure to laser radiation and potential for material vaporization.

Choosing the Right Welding Method for Your Application

Friction stir welding excels in joining aluminum alloys and dissimilar materials with minimal distortion and high-strength joints, making it ideal for aerospace and automotive applications requiring robust structural integrity. Laser welding offers precise, high-speed welding with narrow heat-affected zones, suited for delicate or thin materials and industries like electronics and medical device manufacturing. Selecting the right welding method depends on factors such as material type, joint design, production volume, and required mechanical properties, ensuring optimal performance and cost efficiency.

Friction stir welding Infographic

libterm.com

libterm.com