Model predictive control (MPC) is an advanced control strategy that uses dynamic models to predict and optimize future system behavior over a finite time horizon. It continuously updates control inputs by solving an optimization problem, allowing precise handling of multi-variable systems and constraints. Discover how MPC can enhance the performance and stability of your control systems by exploring the details in this article.

Table of Comparison

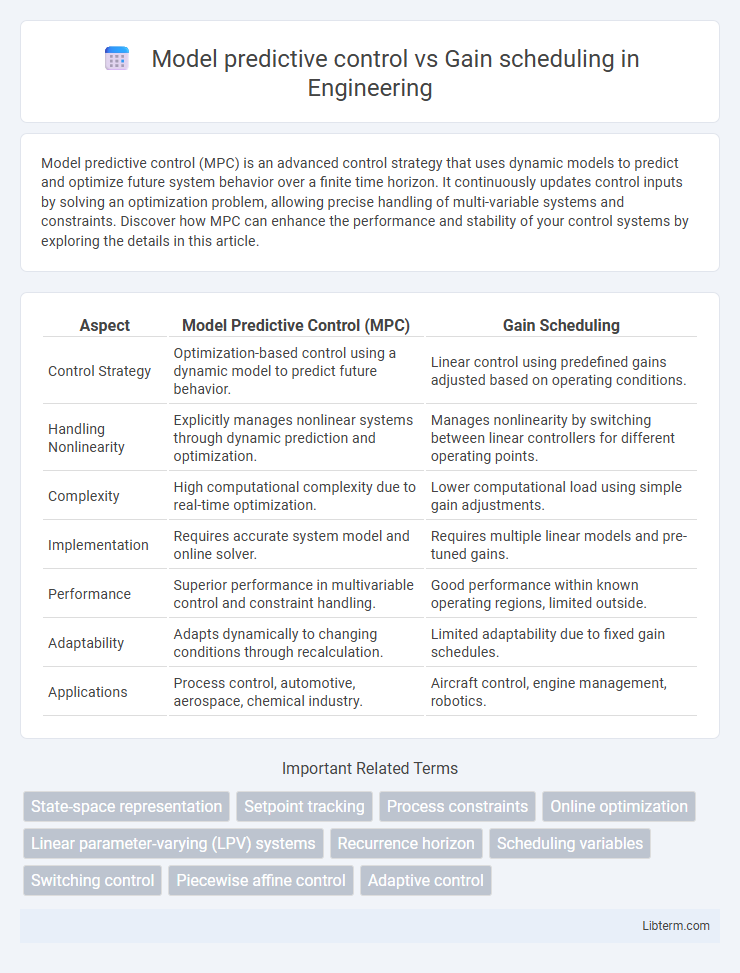

| Aspect | Model Predictive Control (MPC) | Gain Scheduling |

|---|---|---|

| Control Strategy | Optimization-based control using a dynamic model to predict future behavior. | Linear control using predefined gains adjusted based on operating conditions. |

| Handling Nonlinearity | Explicitly manages nonlinear systems through dynamic prediction and optimization. | Manages nonlinearity by switching between linear controllers for different operating points. |

| Complexity | High computational complexity due to real-time optimization. | Lower computational load using simple gain adjustments. |

| Implementation | Requires accurate system model and online solver. | Requires multiple linear models and pre-tuned gains. |

| Performance | Superior performance in multivariable control and constraint handling. | Good performance within known operating regions, limited outside. |

| Adaptability | Adapts dynamically to changing conditions through recalculation. | Limited adaptability due to fixed gain schedules. |

| Applications | Process control, automotive, aerospace, chemical industry. | Aircraft control, engine management, robotics. |

Introduction to Model Predictive Control and Gain Scheduling

Model Predictive Control (MPC) employs a dynamic model to optimize future control actions by solving a constrained optimization problem at each sampling instant, enabling precise handling of multivariable systems and constraints. Gain Scheduling involves adjusting controller parameters based on operating conditions or system states using predefined schedules, offering simplicity in implementation for nonlinear or time-varying processes. MPC provides explicit constraint management and predictive capabilities, whereas Gain Scheduling relies on offline tuning and interpolation between linear controllers to address system variability.

Fundamental Principles of Model Predictive Control

Model Predictive Control (MPC) relies on solving an optimization problem at each control step, using a dynamic model of the system to predict future behavior and optimize control inputs over a finite horizon. Gain scheduling adjusts controller parameters based on operating conditions but lacks the predictive optimization feature integral to MPC. The fundamental principle of MPC is its ability to handle multivariable systems with constraints by continuously updating control actions through real-time prediction and optimization.

Core Concepts of Gain Scheduling

Gain Scheduling involves adjusting controller parameters based on measurable operating conditions, enabling linear controllers to manage nonlinear system dynamics by switching or interpolating gains across different regimes. It relies on predefined scheduling variables linked to system states or external inputs, ensuring smooth transitions and stability throughout the operating range. This approach is particularly effective for systems with well-understood nonlinearities and operating points, contrasting with Model Predictive Control's optimization-based real-time control strategy.

Key Differences Between MPC and Gain Scheduling

Model predictive control (MPC) optimizes future control actions by solving a constrained optimization problem at each time step, considering a predictive model of the system dynamics. In contrast, gain scheduling adjusts controller parameters based on real-time measurements or operating conditions using a predefined set of linear controllers without real-time optimization. MPC handles multivariable, constraint-laden control problems more effectively, whereas gain scheduling is simpler but less flexible with nonlinearities and constraints.

Advantages of Model Predictive Control

Model Predictive Control (MPC) offers superior handling of multivariable systems with constraints, enabling optimal performance by predicting future system behavior over a defined horizon. Unlike Gain Scheduling, MPC dynamically adjusts control actions based on an explicit process model, improving robustness and accuracy in nonlinear or time-varying environments. This predictive capability allows MPC to anticipate disturbances and system changes, leading to enhanced stability and efficiency in complex control applications.

Benefits and Limitations of Gain Scheduling

Gain scheduling offers robust control performance for systems with nonlinear dynamics by switching between multiple linear controllers based on operating conditions, ensuring stability across a wide range of setpoints. Its benefits include simpler implementation and lower computational requirements compared to Model Predictive Control (MPC), making it suitable for real-time applications in aerospace and process industries. Limitations involve potential performance degradation during rapid setpoint changes and the need for extensive tuning of controller gains for each operating region, which can be labor-intensive and less adaptive to unexpected system dynamics.

Application Areas of MPC and Gain Scheduling

Model Predictive Control (MPC) is widely applied in chemical process industries, oil refineries, and food processing plants due to its ability to handle multivariable systems with constraints and optimize performance over a prediction horizon. Gain scheduling excels in aerospace and automotive systems where operating conditions change systematically, enabling controllers to switch gains based on predetermined schedules related to system parameters like speed and altitude. MPC is favored for complex, nonlinear, and constrained processes requiring real-time optimization, while gain scheduling suits applications with well-understood dynamics varying across defined regimes.

Implementation Challenges and Considerations

Model predictive control (MPC) requires significant computational resources due to its real-time optimization of control actions over a prediction horizon, posing challenges for systems with fast dynamics or limited processing capabilities. Gain scheduling involves pre-tuning multiple linear controllers across operating points, demanding extensive system identification and interpolation strategies to maintain stability and performance during transitions. Implementers must balance MPC's flexibility and optimality against gain scheduling's simplicity and lower computational burden, considering the complexity of nonlinearities, available hardware, and robustness requirements.

Performance Comparison: MPC vs Gain Scheduling

Model predictive control (MPC) generally outperforms gain scheduling in handling multivariable systems with constraints, providing optimized control actions by predicting future plant behavior through a dynamic model. Gain scheduling relies on pre-defined linear controllers switched based on operating conditions, which can lead to suboptimal performance during rapid setpoint changes or nonlinear dynamics. MPC's ability to incorporate constraint handling and predictive optimization results in better stability, robustness, and overall control performance compared to gain scheduling approaches.

Choosing the Right Control Strategy for Your System

Model predictive control (MPC) excels in handling multivariable systems with constraints by optimizing future control moves based on a dynamic model, making it ideal for complex, nonlinear processes requiring precise trajectory tracking. Gain scheduling is advantageous for systems with parameters that change predictably over operating conditions, as it switches between predefined linear controllers to maintain stability and performance across varying regimes. Selecting the right control strategy depends on system complexity, presence of constraints, and desired adaptability, with MPC favored for advanced control tasks and gain scheduling suitable for simpler, parameter-varying environments.

Model predictive control Infographic

libterm.com

libterm.com