Principal stress represents the maximum and minimum normal stresses acting on a particular plane within a material, occurring where shear stress is zero. Understanding principal stresses is crucial for predicting material failure and ensuring structural integrity under different loading conditions. Explore the rest of the article to learn how calculating principal stresses can optimize your design and safety measures.

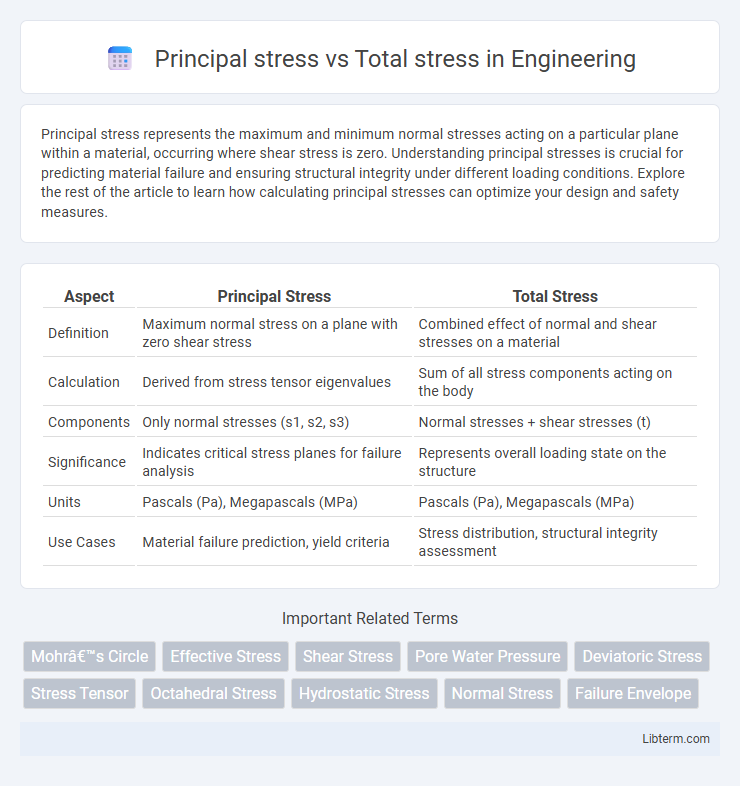

Table of Comparison

| Aspect | Principal Stress | Total Stress |

|---|---|---|

| Definition | Maximum normal stress on a plane with zero shear stress | Combined effect of normal and shear stresses on a material |

| Calculation | Derived from stress tensor eigenvalues | Sum of all stress components acting on the body |

| Components | Only normal stresses (s1, s2, s3) | Normal stresses + shear stresses (t) |

| Significance | Indicates critical stress planes for failure analysis | Represents overall loading state on the structure |

| Units | Pascals (Pa), Megapascals (MPa) | Pascals (Pa), Megapascals (MPa) |

| Use Cases | Material failure prediction, yield criteria | Stress distribution, structural integrity assessment |

Introduction to Stress in Materials

Principal stress represents the maximum and minimum normal stresses acting on specific planes where shear stress is zero, essential for understanding the material's failure criteria. Total stress encompasses both normal and shear components present in a material under load, reflecting the complete state of stress at a point. Analyzing principal stresses enables engineers to predict fracture, yielding, and deformation more accurately than evaluating total stress alone.

Defining Principal Stress

Principal stress refers to the maximum and minimum normal stresses acting on particular planes where shear stress is zero, representing critical stress components in a material under load. Total stress encompasses all stress components, including normal and shear stresses, at any given point within a structure. Defining principal stress is essential for accurately assessing material failure and designing safe engineering structures by identifying the orientation and magnitude of maximum normal stresses.

Understanding Total Stress

Total stress represents the overall internal force per unit area within a material, encompassing both normal and shear stress components acting on a specific plane. It includes contributions from external loads, pore water pressure in soils, and other environmental factors, making it essential for evaluating material or soil stability under actual loading conditions. Understanding total stress allows engineers to assess how forces distribute within a structure or soil mass, which is critical for designing safe foundations, retaining walls, and other geotechnical applications.

Principal Stress vs Total Stress: Key Differences

Principal stress represents the maximum or minimum normal stress acting on particular planes where shear stress is zero, providing crucial insight into material failure points. Total stress encompasses both the effective stress and pore water pressure within a material, reflecting the entire stress experienced by a soil or rock mass. Understanding these key differences is essential for accurate stress analysis in geotechnical and structural engineering applications.

Calculation Methods for Principal Stress

Principal stress calculation involves transforming the total stress tensor to find normal stresses on planes where shear stress is zero, typically using eigenvalue methods or Mohr's circle. The total stress includes both normal and shear components, while principal stresses represent maximum or minimum normal stresses acting independently on specific planes. Analytical methods solve the characteristic equation derived from the stress tensor, providing accurate principal stress values essential for failure analysis and structural design.

Calculation Methods for Total Stress

Total stress calculation methods involve summing all external forces and loads acting on a material, including applied loads, self-weight, and surficial pressures. Principal stress is derived from the total stress tensor by solving for eigenvalues that represent maximum and minimum normal stresses on specific planes. Accurate total stress assessment relies on integrating stress components through analytical equations, numerical methods like Finite Element Analysis (FEA), or direct measurements from strain gauges.

Factors Affecting Principal and Total Stress

Principal stress is influenced by the orientation and magnitude of applied loads, material anisotropy, and boundary conditions, which determine the directions where normal stresses reach extreme values. Total stress encompasses both the principal stresses and shear stresses acting on the element, affected by external forces, pore water pressure in soils, and structural constraints. Variations in loading patterns, environmental conditions, and material heterogeneity significantly impact the calculation and distribution of both principal and total stresses in engineering applications.

Practical Applications in Engineering

Principal stress identifies the maximum and minimum normal stresses on specific planes, crucial for analyzing failure in structural elements like beams and pressure vessels. Total stress encompasses all stresses, including principal, shear, and residual stresses, providing a comprehensive view essential for fatigue analysis and safety assessments. Engineers use principal stress to design components resistant to yielding and fracture, while total stress guides the evaluation of stress states under complex loading conditions.

Common Misconceptions

Principal stress is often misunderstood as the total stress in a material, but it actually represents the maximum normal stress acting on specific planes where shear stress is zero. Total stress includes both normal and shear components acting on any plane within the material, making it a more comprehensive measure of the stress state. Confusing principal stress with total stress can lead to errors in failure analysis and material design, as principal stress values do not capture the complete stress distribution.

Summary and Conclusion

Principal stress represents the maximum and minimum normal stresses acting on particular planes where shear stress is zero, offering critical insights into material failure regions. Total stress encompasses both effective stress and pore water pressure, reflecting the complete stress state within soils or rocks. Understanding the distinction between principal stress and total stress is essential for accurate geotechnical analysis and safe structural design.

Principal stress Infographic

libterm.com

libterm.com