Ball bearings reduce friction and enhance the smooth rotation of moving parts in machinery, increasing efficiency and lifespan. They are essential in applications ranging from small household appliances to large industrial machines. Discover how to choose the right ball bearings for your specific needs in the rest of this article.

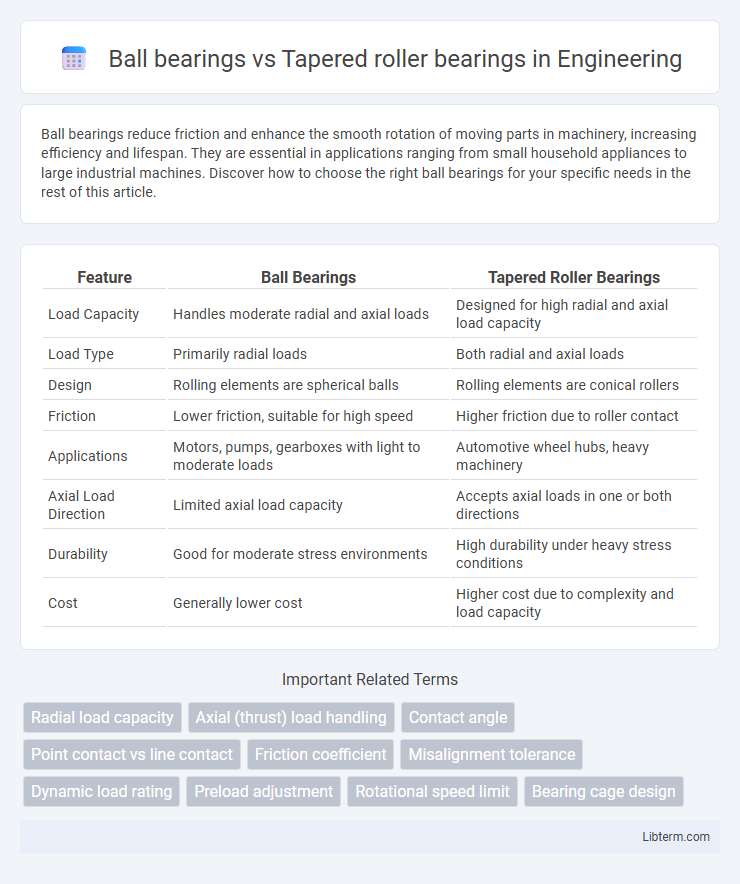

Table of Comparison

| Feature | Ball Bearings | Tapered Roller Bearings |

|---|---|---|

| Load Capacity | Handles moderate radial and axial loads | Designed for high radial and axial load capacity |

| Load Type | Primarily radial loads | Both radial and axial loads |

| Design | Rolling elements are spherical balls | Rolling elements are conical rollers |

| Friction | Lower friction, suitable for high speed | Higher friction due to roller contact |

| Applications | Motors, pumps, gearboxes with light to moderate loads | Automotive wheel hubs, heavy machinery |

| Axial Load Direction | Limited axial load capacity | Accepts axial loads in one or both directions |

| Durability | Good for moderate stress environments | High durability under heavy stress conditions |

| Cost | Generally lower cost | Higher cost due to complexity and load capacity |

Introduction to Ball Bearings vs Tapered Roller Bearings

Ball bearings utilize spherical rolling elements to reduce rotational friction and support radial and axial loads, ideal for high-speed applications with moderate load capacity. Tapered roller bearings employ conical rollers designed to manage large radial and thrust loads simultaneously, making them suitable for heavy-duty machinery. The key distinction lies in load handling: ball bearings excel in speed and lighter loads, whereas tapered roller bearings provide enhanced durability under intense pressure and combined loads.

Design Differences: Ball Bearings vs Tapered Roller Bearings

Ball bearings feature spherical rolling elements that provide low friction and support primarily radial loads, making them ideal for high-speed applications. Tapered roller bearings utilize conical rollers that handle combined radial and axial loads with greater load capacity due to their geometry. The distinct design difference lies in the shape and contact angle of the rolling elements, impacting their load distribution and performance characteristics.

Load Handling Capabilities: Radial and Axial Loads

Ball bearings excel in handling moderate radial loads and limited axial loads due to their point contact design, making them ideal for applications with predominantly radial forces. Tapered roller bearings offer superior load handling capabilities for both radial and axial loads because their line contact allows them to support heavy radial loads alongside significant axial forces. This makes tapered roller bearings the preferred choice in scenarios requiring durability under combined load conditions, such as automotive and industrial machinery.

Applications in Industry and Automotive

Ball bearings excel in high-speed applications with moderate load capacities, commonly used in electric motors, pumps, and automotive components such as alternators and wheel hubs. Tapered roller bearings handle heavy axial and radial loads, making them ideal for automotive wheel hubs, gearboxes, and heavy machinery in construction or mining industries. In industrial settings, tapered roller bearings provide durability and load capacity for conveyor systems and material handling equipment, outperforming ball bearings in harsh environments requiring robust performance.

Performance in High-Speed Environments

Ball bearings excel in high-speed environments due to their low friction and ability to handle high rotational speeds with minimal heat generation, making them ideal for applications such as electric motors and turbines. Tapered roller bearings, while robust and capable of handling higher radial and axial loads, generate more friction and heat at elevated speeds, limiting their performance in ultra-high-speed applications. Thus, ball bearings provide superior performance in scenarios demanding high rotational velocity and precision.

Durability and Lifespan Comparison

Ball bearings typically offer moderate durability suitable for applications with radial loads and moderate speeds, while tapered roller bearings excel in handling combined radial and axial loads under heavy-duty conditions, resulting in a longer lifespan. The tapered roller design distributes stress more evenly across the raceways and rollers, reducing wear and extending service life, especially in high-load, shock, and misalignment scenarios. Lifespan of tapered roller bearings can exceed that of ball bearings by up to 30-40% in industrial and automotive applications subject to heavy loads and harsh environments.

Maintenance and Lubrication Requirements

Ball bearings require regular lubrication with grease or oil to reduce friction and prevent wear, typically needing less frequent maintenance due to their simple design. Tapered roller bearings demand precise lubrication methods, often using high-quality grease or oil with additives to handle heavy radial and axial loads, and require more frequent inspection to monitor for contamination and wear. Both types benefit from clean operating environments, but tapered roller bearings' maintenance schedules are generally more rigorous due to their complex load-handling characteristics.

Cost Considerations and Availability

Ball bearings generally offer lower initial costs and wider availability due to their standardized design and mass production, making them ideal for applications requiring high-speed rotation with moderate load capacity. Tapered roller bearings, while more expensive upfront, provide superior load-handling capabilities and durability under combined radial and axial loads, often justifying the higher investment in heavy-duty or industrial machinery. Availability of tapered bearings may be more limited and lead times longer because of their specialized design and manufacturing complexity compared to the more commonly stocked ball bearings.

Installation and Replacement Procedures

Ball bearings require precise alignment during installation to prevent premature wear and ensure smooth rotation, often involving careful lubrication and seating within rigid housings. Tapered roller bearings demand meticulous adjustment of the bearing preload by tightening the cones and cups to avoid misalignment and uneven load distribution, necessitating specialized tools such as torque wrenches and bearing pullers for both installation and replacement. Proper replacement of both bearing types involves thorough cleaning of the housing, inspection for damage, and adherence to manufacturer torque specifications to optimize bearing life and performance.

Choosing the Right Bearing for Your Needs

Ball bearings excel in high-speed, low-friction applications with primarily radial loads, offering smooth rotation and minimal noise. Tapered roller bearings handle both radial and axial loads effectively, making them ideal for heavy-duty machinery requiring load capacity and durability. Selecting the right bearing depends on load type, speed requirements, and application environment to ensure optimal performance and longevity.

Ball bearings Infographic

libterm.com

libterm.com