Permanent magnets generate a consistent magnetic field without requiring external power, making them essential in various applications from electric motors to data storage devices. Their ability to maintain magnetism over time depends on the material composition and manufacturing process. Explore how permanent magnets impact technology and your everyday life in the rest of this article.

Table of Comparison

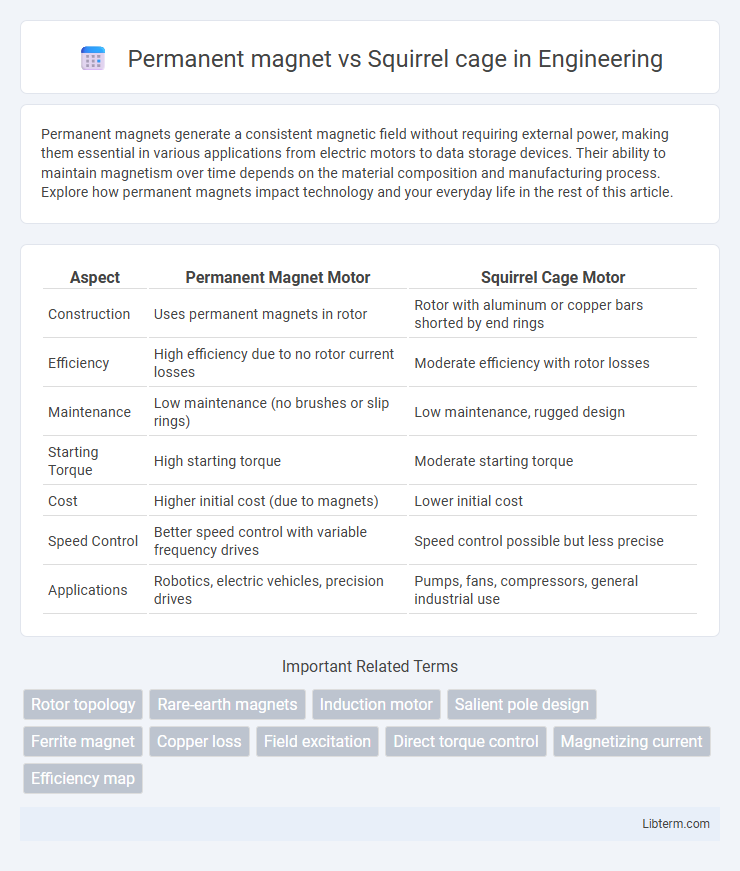

| Aspect | Permanent Magnet Motor | Squirrel Cage Motor |

|---|---|---|

| Construction | Uses permanent magnets in rotor | Rotor with aluminum or copper bars shorted by end rings |

| Efficiency | High efficiency due to no rotor current losses | Moderate efficiency with rotor losses |

| Maintenance | Low maintenance (no brushes or slip rings) | Low maintenance, rugged design |

| Starting Torque | High starting torque | Moderate starting torque |

| Cost | Higher initial cost (due to magnets) | Lower initial cost |

| Speed Control | Better speed control with variable frequency drives | Speed control possible but less precise |

| Applications | Robotics, electric vehicles, precision drives | Pumps, fans, compressors, general industrial use |

Introduction to Permanent Magnet and Squirrel Cage Motors

Permanent magnet motors utilize magnets embedded in the rotor to create a consistent magnetic field, enhancing efficiency and torque density. Squirrel cage motors feature a rotor composed of conductive bars short-circuited by end rings, offering ruggedness and low maintenance. Both motor types serve critical roles in industrial applications, with permanent magnet motors favored for precision control and squirrel cage motors for reliability and cost-effectiveness.

Fundamental Working Principles

Permanent magnet motors operate by utilizing the magnetic field generated by permanent magnets embedded in the rotor, which interact with the stator's electromagnetic field to produce torque. Squirrel cage induction motors function based on electromagnetic induction, where the rotating magnetic field of the stator induces current in the conductive bars of the rotor, creating torque through the interaction of magnetic fields. The key distinction lies in the rotor construction: permanent magnets provide a constant magnetic field, while squirrel cage rotors rely on induced currents for magnetic field generation.

Construction and Design Differences

Permanent magnet motors feature magnets fixed on the rotor, eliminating the need for rotor windings, resulting in a compact and efficient design. Squirrel cage motors incorporate a rotor made of laminated iron with conductive bars short-circuited by end rings, creating a robust and simple structure ideal for high durability. The distinct construction impacts performance, with permanent magnet rotors offering higher efficiency and squirrel cage rotors providing ruggedness and ease of maintenance.

Efficiency and Performance Comparison

Permanent magnet motors exhibit higher efficiency and superior performance compared to squirrel cage induction motors due to reduced rotor losses and improved power density. The absence of rotor windings in permanent magnet motors minimizes energy dissipation, resulting in efficiencies often exceeding 90%, whereas squirrel cage motors typically achieve efficiencies around 85-90%. Enhanced torque density and better speed control in permanent magnet motors make them ideal for high-performance applications requiring precise motion and energy savings.

Energy Consumption Analysis

Permanent magnet motors typically offer higher energy efficiency compared to squirrel cage induction motors due to reduced rotor losses and improved power factor. The absence of rotor current in permanent magnet designs minimizes copper and iron losses, resulting in lower overall energy consumption. In industrial applications, this efficiency advantage often leads to significant cost savings and reduced environmental impact over the motor's operational lifespan.

Maintenance Requirements and Longevity

Permanent magnet motors typically demand lower maintenance due to their simplified construction and absence of brushes or slip rings, reducing wear and tear. Squirrel cage induction motors require periodic inspection and maintenance of bearings, cooling systems, and electrical connections to ensure longevity. The robust design of squirrel cage motors often allows for longer operational life under harsh conditions, while permanent magnet motors can degrade over time if exposed to high temperatures or demagnetization risks.

Cost Implications and Investment Considerations

Permanent magnet motors generally have higher upfront costs due to the expensive rare-earth materials required for magnets, impacting initial investment budgets. Squirrel cage induction motors offer lower initial costs and simpler construction, making them more economical for large-scale industrial applications. Long-term investment considerations must include maintenance expenses, with squirrel cage motors typically incurring higher operating costs due to lower efficiency and increased wear over time compared to permanent magnet motors.

Application Suitability and Industry Uses

Permanent magnet motors excel in applications requiring high efficiency and precise speed control, commonly found in robotics, electric vehicles, and aerospace industries. Squirrel cage induction motors dominate heavy-duty industrial sectors like manufacturing, mining, and HVAC due to their robustness, low maintenance, and cost-effectiveness. Selection between the two hinges on factors such as performance demands, operational environment, and energy efficiency requirements specific to the industry use case.

Environmental Impact and Sustainability

Permanent magnet motors generally exhibit higher energy efficiency compared to squirrel cage induction motors, reducing overall carbon emissions during operation. The production of permanent magnets often involves rare earth elements, which raises concerns about environmental degradation and resource scarcity. Squirrel cage motors, while less efficient, rely on more abundant and recyclable materials, offering advantages in sustainability and end-of-life recycling processes.

Choosing the Right Motor for Your Needs

Permanent magnet motors offer higher efficiency and better performance at variable speeds, making them ideal for applications requiring precise control and energy savings. Squirrel cage induction motors are robust, cost-effective, and low-maintenance, suitable for heavy-duty industrial environments with constant-speed requirements. Choosing the right motor depends on factors like load variability, energy efficiency priorities, initial costs, and maintenance capabilities.

Permanent magnet Infographic

libterm.com

libterm.com