A reamer is a precision cutting tool used to enlarge and finish holes to exact dimensions with smooth surfaces. It ensures accurate hole sizing and improves the fit of mechanical parts, making it essential in metalworking and manufacturing processes. Explore the rest of the article to discover how a reamer can enhance your machining projects.

Table of Comparison

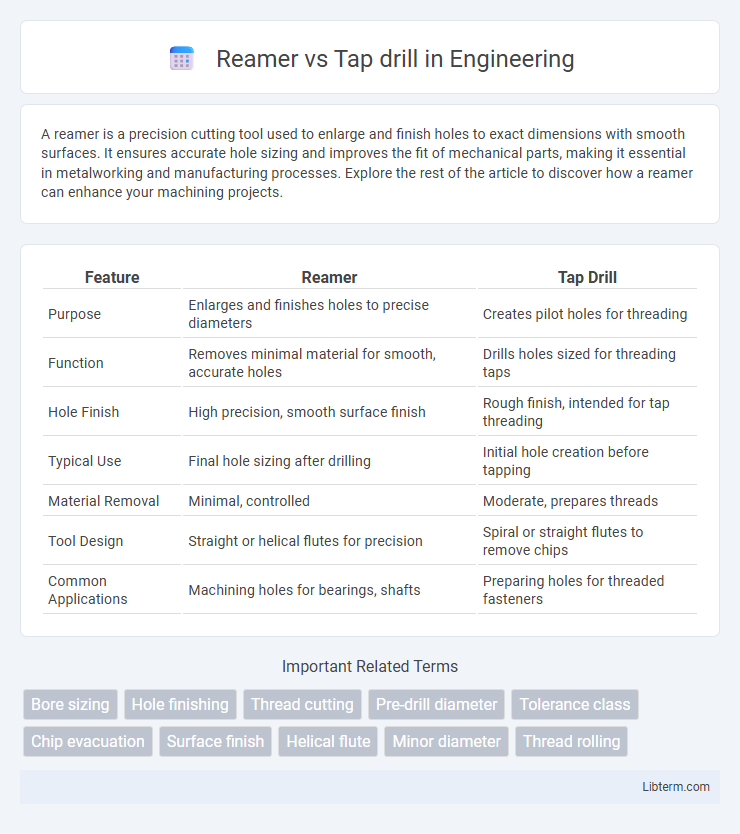

| Feature | Reamer | Tap Drill |

|---|---|---|

| Purpose | Enlarges and finishes holes to precise diameters | Creates pilot holes for threading |

| Function | Removes minimal material for smooth, accurate holes | Drills holes sized for threading taps |

| Hole Finish | High precision, smooth surface finish | Rough finish, intended for tap threading |

| Typical Use | Final hole sizing after drilling | Initial hole creation before tapping |

| Material Removal | Minimal, controlled | Moderate, prepares threads |

| Tool Design | Straight or helical flutes for precision | Spiral or straight flutes to remove chips |

| Common Applications | Machining holes for bearings, shafts | Preparing holes for threaded fasteners |

Understanding Reamers and Tap Drills

Reamers are precision cutting tools used to enlarge and finish pre-drilled holes to exact diameters with smooth finishes. Tap drills are specific hole sizes drilled to allow threading taps to cut internal threads accurately without excess force or material removal. Understanding the difference ensures proper tool selection for hole preparation, maximizing dimensional accuracy and thread quality in machining processes.

Key Differences Between Reamers and Tap Drills

Reamers precisely enlarge and finish existing holes to exact dimensions, ensuring smooth surfaces and tight tolerances, whereas tap drills create initial holes to accommodate threading. Reamers produce high-quality, accurately sized holes with fine finishes, while tap drills are sized smaller to allow cutting threads through material deformation. The key difference lies in their applications: reamers are for hole refinement, and tap drills prepare holes for threading processes.

Purpose and Applications of Reamers

Reamers are precision cutting tools designed to enlarge and finish holes to exact diameters with smooth finishes, commonly used in metalworking and manufacturing industries for achieving high tolerance holes. Unlike tap drills, which create threaded holes for screws and bolts, reamers ensure dimensional accuracy and improve the quality of pre-drilled holes by removing small amounts of material. Typical applications include automotive engine parts, aerospace components, and machinery assemblies where precision hole sizing and surface finish are critical.

Purpose and Applications of Tap Drills

Tap drills are specifically designed to create precise pilot holes that match the core diameter of taps, ensuring accurate thread formation in materials. These drill holes facilitate efficient cutting of internal threads in metalworking and manufacturing processes, optimizing thread strength and fit. Tap drills are widely used in applications requiring reliable fastening, such as automotive assembly, aerospace components, and machinery fabrication.

Material Compatibility: Reamers vs Tap Drills

Reamers provide precise hole finishing and are best suited for softer, ductile materials such as aluminum and brass, where smooth surface finish and dimensional accuracy are crucial. Tap drills are typically used to create pilot holes prior to threading in tougher materials like steel and stainless steel, where maintaining proper thread fit and avoiding tool breakage is essential. Selecting the correct tool depends on the material's hardness and machinability, optimizing the machining process for durability and thread integrity.

Precision and Tolerance Comparison

Reamers offer superior precision and tighter tolerance control compared to tap drills by providing smooth and accurate finishing to pre-drilled holes, typically achieving tolerances within +-0.001 inches. Tap drills primarily serve to create threaded holes with less emphasis on exact diameter control, often resulting in looser tolerances around +-0.002 to +-0.005 inches. For applications requiring high dimensional accuracy and fine surface finishes, reaming is the preferred method over tapping due to its enhanced precision and consistency.

Common Types of Reamers and Tap Drills

Common reamers include hand reamers, machine reamers, and adjustable reamers, each designed for precise hole finishing and sizing. Tap drills vary by thread type and size, with common types such as UNC (Unified National Coarse), UNF (Unified National Fine), and metric taps requiring specific drill sizes for optimal thread engagement. Selecting the correct reamer or tap drill depends on factors like hole tolerance, material, and thread pitch to ensure proper fit and function.

Advantages and Disadvantages of Each Tool

Reamers provide precise hole sizing and smooth finishes, ideal for applications requiring tight tolerances, but can be slower and more expensive than tap drills. Tap drills create internal threads efficiently and are essential for threading operations, yet they may produce less accurate hole dimensions and rougher surfaces. Choosing between a reamer and tap drill depends on the balance needed between hole accuracy and threading speed.

Selecting the Right Tool for Your Project

Selecting the right tool between a reamer and a tap drill depends on your project's purpose and precision requirements. Reamers provide accurate hole sizing and smooth finishes by enlarging existing holes, ideal for alignment or clearance purposes. Tap drills create threads inside a hole for fastener insertion, so choosing the correct drill size to match thread specifications ensures proper thread engagement.

Best Practices for Using Reamers and Tap Drills

Best practices for using reamers involve selecting the correct size slightly larger than the initial hole to ensure precise hole dimensions and smooth finishes, while maintaining proper alignment and consistent feed rates to avoid tool deflection and damage. For tap drills, choosing the optimal drill diameter based on thread percentage (typically between 75%-85%) guarantees proper thread engagement and strength, alongside using appropriate lubrication and controlled tapping speeds to prevent tool breakage and achieve clean threads. Both tools require regular inspection and maintenance to preserve accuracy and extend tool life, enhancing overall machining quality.

Reamer Infographic

libterm.com

libterm.com