Extrusion is a manufacturing process where material is forced through a shaped die to create objects with a fixed cross-sectional profile, commonly used for metals, plastics, and ceramics. This technique offers precise control over dimensions and material properties, making it ideal for producing complex shapes efficiently and with minimal waste. Explore the full article to understand how extrusion can enhance your production capabilities and product quality.

Table of Comparison

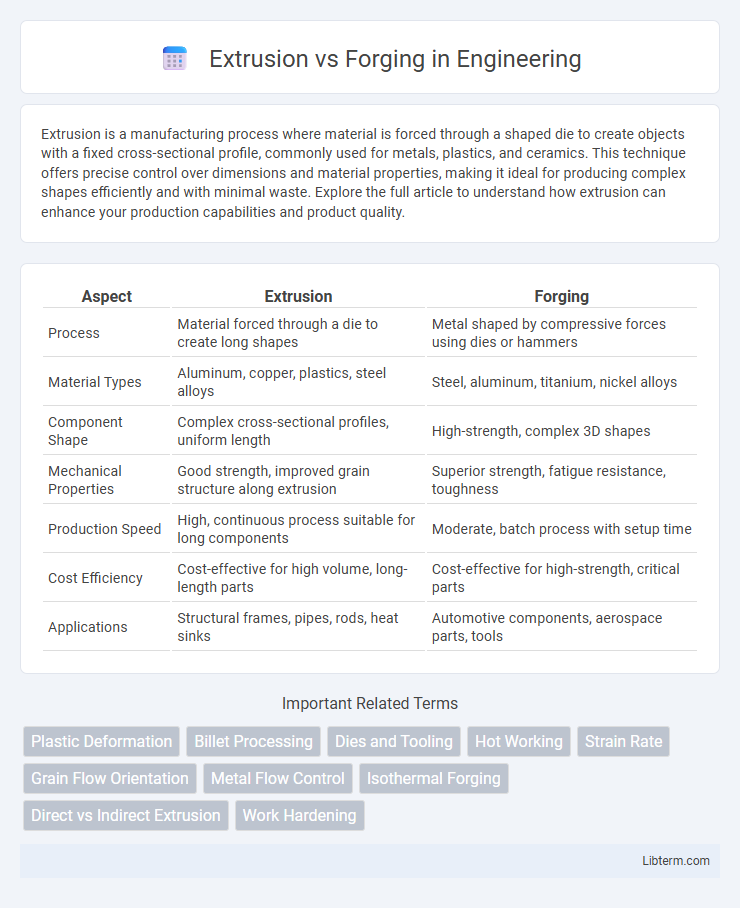

| Aspect | Extrusion | Forging |

|---|---|---|

| Process | Material forced through a die to create long shapes | Metal shaped by compressive forces using dies or hammers |

| Material Types | Aluminum, copper, plastics, steel alloys | Steel, aluminum, titanium, nickel alloys |

| Component Shape | Complex cross-sectional profiles, uniform length | High-strength, complex 3D shapes |

| Mechanical Properties | Good strength, improved grain structure along extrusion | Superior strength, fatigue resistance, toughness |

| Production Speed | High, continuous process suitable for long components | Moderate, batch process with setup time |

| Cost Efficiency | Cost-effective for high volume, long-length parts | Cost-effective for high-strength, critical parts |

| Applications | Structural frames, pipes, rods, heat sinks | Automotive components, aerospace parts, tools |

Introduction to Extrusion and Forging

Extrusion is a manufacturing process where material, typically metal or plastic, is pushed or drawn through a die to create objects of a fixed cross-sectional profile, offering high precision and efficient production of complex shapes. Forging involves shaping metal using compressive forces, often delivered by a hammer or press, which enhances mechanical properties like strength and fatigue resistance by refining the grain structure. Both processes are essential in industries such as automotive, aerospace, and construction for producing durable parts with specific mechanical characteristics.

Definition and Process Overview

Extrusion is a manufacturing process where a material, typically metal or plastic, is forced through a die to create objects with a fixed cross-sectional profile. Forging involves shaping metal using localized compressive forces, often delivered by a hammer or a press, to improve the metal's mechanical properties through plastic deformation. Both processes enhance material strength but differ significantly in technique: extrusion forms continuous shapes by pushing material through a die, while forging reshapes solid metal pieces through impact or pressure.

Key Differences Between Extrusion and Forging

Extrusion involves forcing material through a die to create objects with a fixed cross-sectional profile, while forging reshapes metal using compressive forces, often with hammering or pressing. Extrusion typically produces uniform cross-sections and is ideal for aluminum and softer metals, whereas forging provides superior mechanical properties and strength by refining the internal grain structure of metals like steel. The key differences lie in their manufacturing processes, resulting material properties, and applications, with extrusion optimizing shape complexity and forging enhancing durability and toughness.

Material Compatibility and Applications

Extrusion offers superior compatibility with ductile metals such as aluminum, copper, and magnesium, enabling complex shapes and uniform cross-sections often used in automotive and aerospace components. Forging excels with high-strength materials like steel and titanium, enhancing mechanical properties through grain refinement, making it ideal for heavy-duty applications including aircraft structural parts and industrial machinery. Both processes optimize material performance but differ in application based on the metal's ductility and the mechanical strength requirements.

Strength and Mechanical Properties

Extrusion produces components with uniform grain flow and enhanced tensile strength, ideal for complex cross-sections with good surface finish. Forging refines the internal grain structure, resulting in superior mechanical properties such as higher fatigue resistance, toughness, and impact strength. Typically, forged parts exhibit greater strength and durability compared to extruded parts due to the compressive forces applied during the forging process.

Surface Finish and Dimensional Accuracy

Extrusion typically produces parts with smoother surface finishes due to the continuous metal flow through a die, resulting in less surface irregularities compared to forging. Forging offers superior dimensional accuracy mainly because of the precise die and controlled deformation forces, minimizing internal defects and ensuring tighter tolerances. While extrusion excels in achieving consistent surface texture, forging provides better control over final dimensions and mechanical properties.

Production Speed and Efficiency

Extrusion typically offers higher production speeds compared to forging due to its continuous process that shapes metal by forcing it through a die, making it ideal for producing long, uniform profiles efficiently. Forging, involving the deformation of metal under high pressure, is generally slower but produces stronger, more durable components with superior mechanical properties. Manufacturers prioritize extrusion for large-volume, high-speed production runs, while forging is favored for parts requiring enhanced strength and reliability despite longer cycle times.

Cost Comparison: Extrusion vs Forging

Extrusion generally offers lower tooling and production costs compared to forging, especially for complex cross-sectional shapes, due to its continuous process and reduced material waste. Forging involves higher initial setup and equipment expenses but provides superior mechanical properties, justifying the cost in high-strength applications. The choice between extrusion and forging depends on production volume, material characteristics, and final part requirements, with extrusion favored for cost-effective mass production and forging for performance-critical components.

Environmental and Energy Considerations

Extrusion typically consumes more energy than forging due to the continuous heating and pressing required to shape metals, yet it allows for precise material use, reducing scrap waste. Forging, while often involving high-pressure deformation at elevated temperatures, generally results in stronger components with less post-processing, lowering overall energy expenditure in production. Both methods impact carbon emissions, but forging's ability to enhance material properties often leads to longer-lasting products, decreasing environmental impact over the lifecycle.

Choosing the Right Process for Your Project

Selecting between extrusion and forging depends on the project's material requirements, desired mechanical properties, and part complexity. Extrusion excels in producing long, uniform cross-sections with excellent surface finish and dimensional accuracy, ideal for aluminum and copper alloys. Forging offers superior strength and fatigue resistance by refining metal grain structure, making it suitable for critical components in aerospace and automotive industries.

Extrusion Infographic

libterm.com

libterm.com