Resistance welding utilizes the heat generated from electrical resistance to join metals efficiently and precisely. This technique is widely applied in automotive and manufacturing industries due to its speed and strong weld quality. Explore the full article to understand how resistance welding can enhance your metal fabrication projects.

Table of Comparison

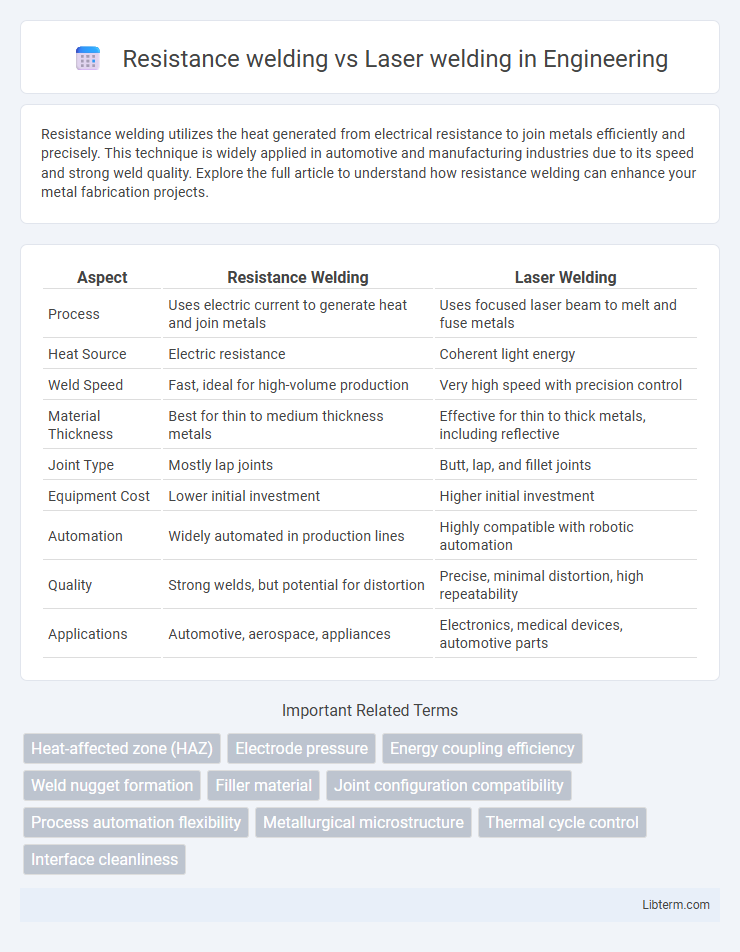

| Aspect | Resistance Welding | Laser Welding |

|---|---|---|

| Process | Uses electric current to generate heat and join metals | Uses focused laser beam to melt and fuse metals |

| Heat Source | Electric resistance | Coherent light energy |

| Weld Speed | Fast, ideal for high-volume production | Very high speed with precision control |

| Material Thickness | Best for thin to medium thickness metals | Effective for thin to thick metals, including reflective |

| Joint Type | Mostly lap joints | Butt, lap, and fillet joints |

| Equipment Cost | Lower initial investment | Higher initial investment |

| Automation | Widely automated in production lines | Highly compatible with robotic automation |

| Quality | Strong welds, but potential for distortion | Precise, minimal distortion, high repeatability |

| Applications | Automotive, aerospace, appliances | Electronics, medical devices, automotive parts |

Introduction to Resistance and Laser Welding

Resistance welding uses electrical current and pressure to join metals by heating the interface through electrical resistance, enabling efficient and strong welds primarily for sheet metals and thin materials. Laser welding employs a focused laser beam to deliver high-intensity heat, creating precise, narrow, and deep welds with minimal heat-affected zones, ideal for intricate and high-speed applications. Both techniques serve distinct industrial needs with differences in heat source, speed, and material compatibility.

Fundamental Principles of Resistance Welding

Resistance welding relies on the principle of generating heat through electrical resistance at the interface of the materials to be joined, causing localized melting and fusion. This process typically involves applying pressure and passing a high current through the metal pieces, which produces intense, controlled heat precisely where the electrodes contact the workpieces. The core elements affecting weld quality in resistance welding include electrode force, current magnitude, and welding time, which ensure consistent and strong joints.

Core Mechanisms of Laser Welding

Laser welding utilizes a focused laser beam to generate intense heat, causing localized melting and fusion of materials, which contrasts with resistance welding that relies on electrical current passing through materials to produce heat via resistance. The core mechanism in laser welding is the absorption of laser energy by the metal surface, leading to rapid melting and solidification with minimal thermal distortion. This precise energy control allows for deep penetration welds, high-speed processing, and suitability for delicate or small-scale components in industries like aerospace and medical device manufacturing.

Materials Suitability: Resistance vs Laser Welding

Resistance welding is highly effective for joining conductive metals such as steel, aluminum, and copper alloys, excelling in applications requiring rapid, high-strength bonds in sheet metal and wire forms. Laser welding offers superior versatility, capable of welding a broader range of materials including dissimilar metals, reflective materials, and thin, heat-sensitive components with precise, narrow heat-affected zones. Material suitability depends on factors like thermal conductivity, thickness, and joint design, with resistance welding favoring electrically conductive and thicker materials, while laser welding accommodates complex geometries and delicate substrates.

Precision and Weld Quality Comparison

Resistance welding offers consistent weld quality with moderate precision, suitable for joining thin sheets and high-volume production due to controlled heat generation and pressure. Laser welding excels in precision, providing narrow, deep welds with minimal thermal distortion, ideal for intricate designs and materials requiring fine detail. The laser process achieves superior weld quality by enabling higher energy density and precise control over weld parameters, resulting in stronger and cleaner joints.

Speed and Efficiency in Production

Resistance welding offers rapid cycle times and high energy efficiency, making it ideal for high-volume production with consistent weld quality. Laser welding provides even faster processing speeds and greater precision, reducing heat-affected zones and minimizing post-weld finishing. Combining laser welding technology with automation can significantly enhance production throughput and reduce overall manufacturing costs.

Cost Considerations and Equipment Investment

Resistance welding generally requires lower initial equipment investment compared to laser welding, making it cost-effective for mass production of standard joints. Laser welding involves higher upfront costs due to advanced optics and precise control systems but offers savings in reduced material waste and minimal post-processing. Long-term operational expenses tend to be lower for laser welding in high-precision or complex applications, despite the steep initial capital outlay.

Industrial Applications and Use Cases

Resistance welding excels in automotive manufacturing for joining thin metal sheets rapidly and cost-effectively, making it ideal for mass production of car bodies and electrical components. Laser welding offers precise control and minimal heat distortion, suited for aerospace and medical device industries where intricate, high-quality welds on delicate or complex parts are critical. Both technologies enhance assembly lines, with resistance welding favored for volume and durability, while laser welding is preferred for precision and versatility in advanced industrial applications.

Safety and Environmental Impact

Resistance welding generates minimal emissions and uses less energy compared to laser welding, reducing environmental impact and lowering workplace hazards associated with fumes and UV radiation. Laser welding, while offering precision and speed, requires stringent safety measures to protect operators from high-intensity laser exposure and potential eye injuries. Both methods demand appropriate ventilation and protective equipment to ensure safe operation, but resistance welding typically has a safer environmental profile due to lower energy consumption and fewer hazardous byproducts.

Choosing Between Resistance and Laser Welding

Choosing between resistance welding and laser welding depends on factors like material type, thickness, and production volume. Resistance welding is ideal for high-volume applications with conductive metals and offers cost-effective, fast joining for thin to medium gauges. Laser welding provides precise, deep welds with minimal heat distortion, making it suitable for intricate designs and thicker or dissimilar materials.

Resistance welding Infographic

libterm.com

libterm.com