A tee joint is a fundamental welding joint where two metal pieces intersect at a 90-degree angle, forming a T shape commonly used in structural frameworks and piping systems. Proper preparation and welding techniques ensure strong, durable connections that can withstand stress and pressure. Explore the rest of the article to master tee joint applications and best practices for your projects.

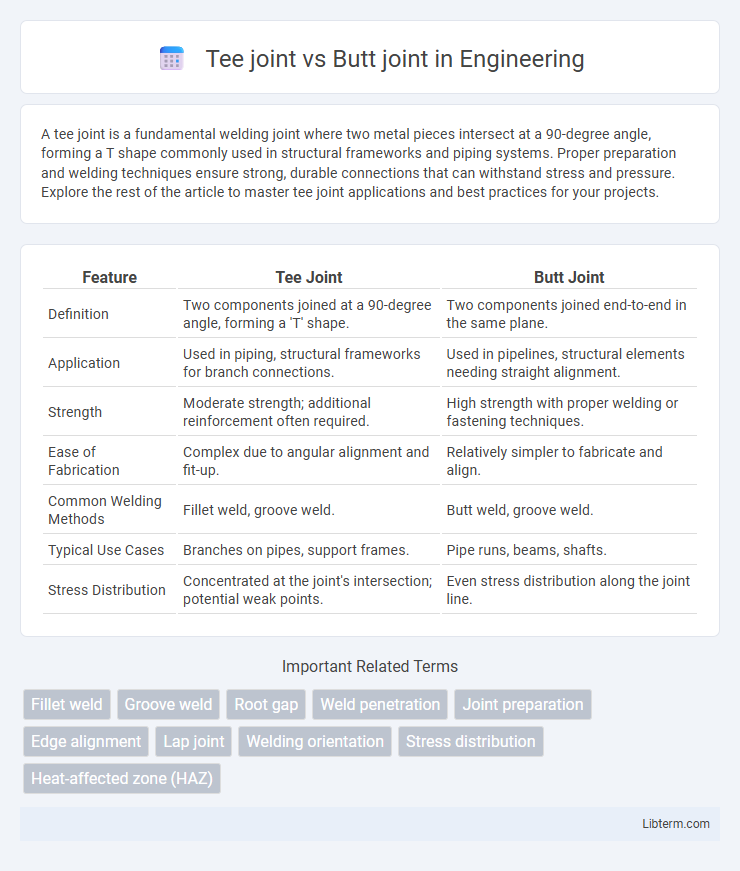

Table of Comparison

| Feature | Tee Joint | Butt Joint |

|---|---|---|

| Definition | Two components joined at a 90-degree angle, forming a 'T' shape. | Two components joined end-to-end in the same plane. |

| Application | Used in piping, structural frameworks for branch connections. | Used in pipelines, structural elements needing straight alignment. |

| Strength | Moderate strength; additional reinforcement often required. | High strength with proper welding or fastening techniques. |

| Ease of Fabrication | Complex due to angular alignment and fit-up. | Relatively simpler to fabricate and align. |

| Common Welding Methods | Fillet weld, groove weld. | Butt weld, groove weld. |

| Typical Use Cases | Branches on pipes, support frames. | Pipe runs, beams, shafts. |

| Stress Distribution | Concentrated at the joint's intersection; potential weak points. | Even stress distribution along the joint line. |

Introduction to Tee Joint and Butt Joint

Tee joints and butt joints are fundamental welding techniques used in metal fabrication, each serving distinct structural purposes. A tee joint is formed when two metal pieces are joined at a 90-degree angle, resembling the letter "T," commonly used in frame and support structures. Butt joints, on the other hand, involve joining two pieces end-to-end in the same plane, providing a smooth and continuous surface ideal for pipelines and sheet metal assemblies.

Definition and Structure of Tee Joint

A tee joint is a welding joint where two metal pieces intersect at a perpendicular or near-perpendicular angle, forming a "T" shape, commonly used in structural frameworks and pipe connections. The structure of a tee joint involves one member positioned vertically and joined to the middle of another member laid flat, providing strong support for load-bearing applications. In contrast, a butt joint connects two pieces end-to-end in the same plane, optimized for seamless and flush surfaces.

Definition and Structure of Butt Joint

A butt joint is a type of weld where two pieces of metal are aligned in the same plane and joined at their edges, creating a smooth, flush surface. This joint structure is commonly used for joining plates or pipes end-to-end, providing strength along the joint line without overlapping materials. In contrast, a tee joint involves one piece perpendicular to the other, forming a T-shape, which is ideal for supporting structures or frames where one component intersects another at a right angle.

Key Differences Between Tee Joint and Butt Joint

Tee joints connect two metal pieces at a 90-degree angle, forming a T shape, while butt joints join two pieces end-to-end in the same plane. Tee joints typically require fillet welding for strength and are common in frame construction, whereas butt joints often use groove welding to create a smooth, continuous surface. The choice between tee joint and butt joint depends on the structural requirements, load direction, and fabrication ease.

Applications of Tee Joint in Welding

Tee joints are extensively used in structural steel fabrication, providing strong connections for frameworks in construction and heavy equipment manufacturing. They are ideal for applications requiring perpendicular joining of pipes or plates, such as in automotive chassis, shipbuilding, and pressure vessels. Their ability to distribute stress evenly makes tee joints suitable for load-bearing components and support structures.

Applications of Butt Joint in Welding

Butt joints are extensively used in structural steel fabrication, pipeline construction, and pressure vessel manufacturing due to their ability to provide strong, continuous welds that withstand high stress and pressure. This joint type is favored in shipbuilding, automotive frames, and aerospace components where precise alignment and load-bearing capacity are critical. High-quality butt welds ensure integrity in critical infrastructures such as bridges and industrial machinery, enhancing durability and safety in demanding environments.

Strength and Durability Comparison

Tee joints provide enhanced strength in perpendicular connections due to increased surface area for welding, making them ideal for structural frameworks. Butt joints, while offering uniform strength along the welded seam, are more susceptible to stress concentrations and require precise preparation to ensure durability. In applications demanding high load-bearing capacity and resistance to dynamic forces, Tee joints generally outperform Butt joints in both strength and long-term durability.

Ease of Fabrication and Assembly

Tee joints offer greater ease of fabrication and assembly due to their simple perpendicular connection, allowing faster alignment and welding with minimal preparation. Butt joints require precise edge preparation and alignment to ensure a uniform, strong weld, which can be more time-consuming and complex. The straightforward geometry of tee joints reduces fabrication time, making them suitable for quicker assembly in structural applications.

Common Industries Using Tee and Butt Joints

Tee joints and butt joints are commonly used in construction, automotive, and aerospace industries due to their structural reliability and ease of fabrication. The construction industry often employs tee joints for frameworks and truss assemblies, while butt joints are favored in pipeline and sheet metal applications for seamless connections. Manufacturing sectors utilize both joints in machinery and equipment assembly, optimizing strength and efficiency based on design requirements.

Choosing the Right Joint for Your Project

Selecting the right joint is crucial for structural integrity and project requirements; a tee joint joins two metal pieces at a 90-degree angle, ideal for frame structures and support applications, while a butt joint connects metal ends in a single line, offering a smooth, flat surface suitable for pipelines and sheet metal fabrication. Consider factors such as load distribution, welding accessibility, and aesthetic finish when choosing between tee joint and butt joint to ensure optimal strength and durability. Proper joint selection enhances welding efficiency and long-term performance in steel construction and metalworking projects.

Tee joint Infographic

libterm.com

libterm.com