Thermal systems efficiently manage heat transfer to optimize energy use in various applications, ranging from industrial processes to residential heating. Understanding the components and operation of these systems can significantly improve your energy efficiency and reduce operational costs. Explore the article to learn how thermal systems work and how they can benefit your specific needs.

Table of Comparison

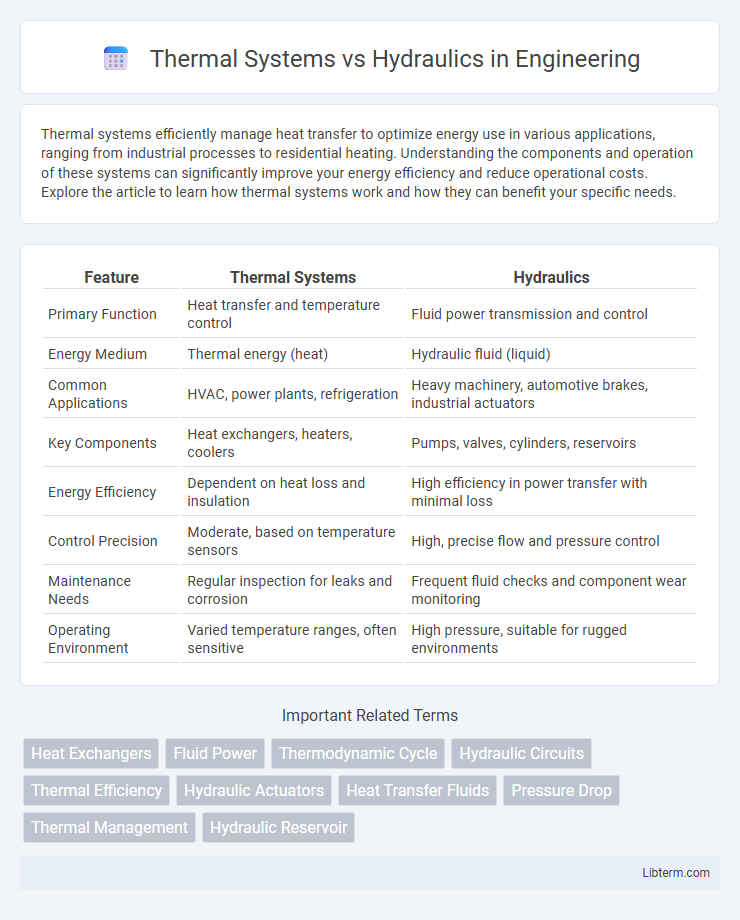

| Feature | Thermal Systems | Hydraulics |

|---|---|---|

| Primary Function | Heat transfer and temperature control | Fluid power transmission and control |

| Energy Medium | Thermal energy (heat) | Hydraulic fluid (liquid) |

| Common Applications | HVAC, power plants, refrigeration | Heavy machinery, automotive brakes, industrial actuators |

| Key Components | Heat exchangers, heaters, coolers | Pumps, valves, cylinders, reservoirs |

| Energy Efficiency | Dependent on heat loss and insulation | High efficiency in power transfer with minimal loss |

| Control Precision | Moderate, based on temperature sensors | High, precise flow and pressure control |

| Maintenance Needs | Regular inspection for leaks and corrosion | Frequent fluid checks and component wear monitoring |

| Operating Environment | Varied temperature ranges, often sensitive | High pressure, suitable for rugged environments |

Introduction to Thermal Systems and Hydraulics

Thermal systems involve the study and application of heat transfer, thermodynamics, and energy conversion processes essential for heating, cooling, and power generation. Hydraulics focuses on the mechanical properties and behavior of fluids, primarily liquids, used to transmit power and control mechanisms in machinery and infrastructure. Understanding these foundational principles enables efficient design and operation of systems such as heat exchangers, pumps, turbines, and hydraulic actuators.

Fundamental Principles of Thermal Systems

Thermal systems operate based on the principles of heat transfer, thermodynamics, and energy conversion, focusing on the management of thermal energy through conduction, convection, and radiation. These systems rely on the laws of thermodynamics, including the conservation of energy and entropy, to regulate temperature and phase changes in fluids and solids. In contrast, hydraulics primarily involves the study of fluid mechanics and the use of pressurized liquids to generate mechanical power and control motion.

Core Concepts of Hydraulic Systems

Hydraulic systems operate on the core principle of fluid power transmission, utilizing incompressible liquids to generate, control, and transmit force and motion. Key components include pumps, actuators, valves, and reservoirs, which work together to convert mechanical energy into hydraulic energy and vice versa. Unlike thermal systems that rely on heat transfer for operation, hydraulics focus on pressure control and fluid dynamics to achieve efficient power delivery in various industrial applications.

Key Components in Thermal and Hydraulic Systems

Thermal systems primarily involve key components such as heat exchangers, boilers, condensers, and thermal storage units, which facilitate heat transfer and temperature regulation. Hydraulic systems rely on essential elements like pumps, valves, cylinders, and hydraulic fluids to transmit power and control fluid flow. Both systems require specialized components designed to optimize energy efficiency and system performance in industrial and mechanical applications.

Differences in Energy Transfer and Storage

Thermal systems transfer energy primarily through heat exchange involving conduction, convection, and radiation, storing energy as sensible or latent heat in materials. Hydraulics transfer energy via fluid pressure and flow, storing energy in pressurized fluids or mechanical components like accumulators. The fundamental difference lies in thermal systems managing thermal energy states while hydraulics handle mechanical energy through fluid dynamics.

Efficiency Comparison: Thermal vs Hydraulic Systems

Thermal systems typically exhibit lower energy efficiency due to heat losses during energy conversion processes, with efficiencies often ranging between 30-40%. Hydraulic systems convert mechanical energy to fluid power with efficiencies up to 90%, minimizing energy dissipation through fluid friction and component wear. In industrial applications, hydraulic systems are preferred for their higher energy efficiency and precise control compared to thermal-based drives.

Applications in Industry: Thermal Systems

Thermal systems in industry are crucial for processes requiring heat transfer, such as power generation, chemical manufacturing, and food processing. These systems optimize energy efficiency through components like heat exchangers, boilers, and refrigeration units, driving productivity and reducing operational costs. Industries heavily rely on thermal systems for temperature control, steam generation, and waste heat recovery to enhance overall performance and sustainability.

Applications in Industry: Hydraulic Systems

Hydraulic systems are extensively employed in industries such as manufacturing, construction, and automotive for their ability to transmit high power through compact components. Applications include heavy machinery operation, hydraulic presses, and fluid power control systems where precise movement and force are critical. The efficiency and reliability of hydraulic systems make them ideal for tasks requiring high load capacity and variable speed control in industrial automation.

Maintenance and Reliability Factors

Thermal systems require rigorous maintenance to prevent heat exchanger fouling and ensure optimal insulation integrity, directly impacting system reliability. Hydraulics demand regular inspection of seals, fluid quality, and pressure levels to avoid leaks and component failures, which are critical for maintaining system efficiency. Both systems rely on condition monitoring and timely preventive maintenance to enhance operational lifespan and reduce downtime.

Future Trends in Thermal and Hydraulic Technologies

Emerging trends in thermal systems emphasize the integration of advanced phase change materials and thermoelectric generators to improve energy efficiency and thermal management in industrial applications. Hydraulic technology is evolving with the adoption of electro-hydraulic actuators and smart fluid control systems, enabling precise, energy-saving operations in automation and heavy machinery. The convergence of IoT-enabled sensors and AI-driven predictive maintenance is driving innovation in both thermal and hydraulic technologies, ensuring higher system reliability and reduced operational costs.

Thermal Systems Infographic

libterm.com

libterm.com