A hollow shaft offers significant weight reduction while maintaining torque transmission efficiency, making it ideal for automotive and industrial applications. Its design helps improve mechanical performance and energy savings by reducing rotational inertia. Explore the rest of this article to understand how a hollow shaft can optimize your machinery's functionality.

Table of Comparison

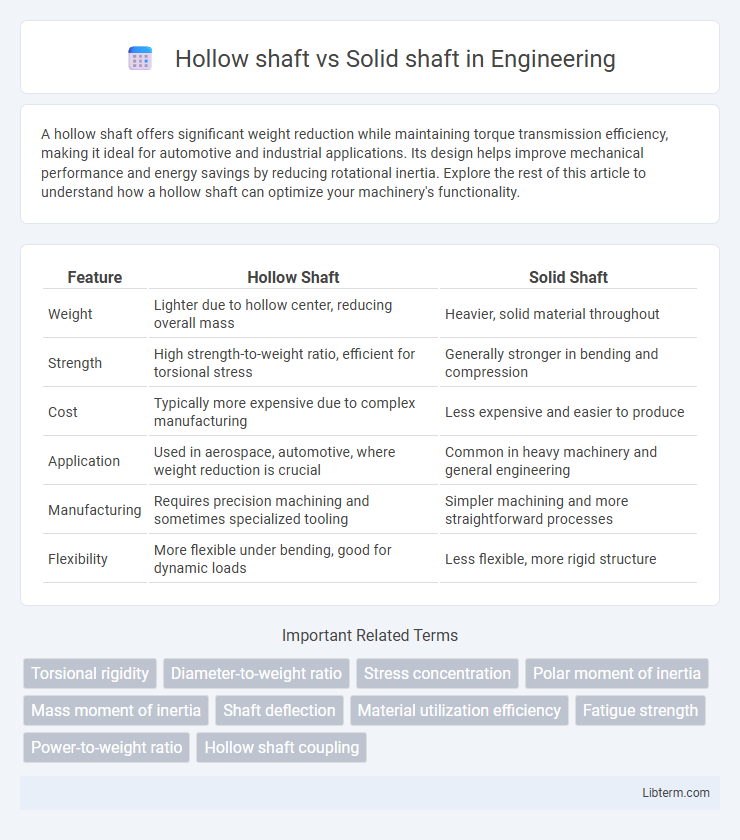

| Feature | Hollow Shaft | Solid Shaft |

|---|---|---|

| Weight | Lighter due to hollow center, reducing overall mass | Heavier, solid material throughout |

| Strength | High strength-to-weight ratio, efficient for torsional stress | Generally stronger in bending and compression |

| Cost | Typically more expensive due to complex manufacturing | Less expensive and easier to produce |

| Application | Used in aerospace, automotive, where weight reduction is crucial | Common in heavy machinery and general engineering |

| Manufacturing | Requires precision machining and sometimes specialized tooling | Simpler machining and more straightforward processes |

| Flexibility | More flexible under bending, good for dynamic loads | Less flexible, more rigid structure |

Introduction to Shafts: Hollow vs Solid

Hollow shafts offer a lightweight alternative to solid shafts by reducing material usage while maintaining high strength and torsional rigidity, making them ideal for applications requiring efficiency and weight savings. Solid shafts provide maximal strength and stiffness for heavy-duty tasks where durability and resistance to bending are critical. The choice between hollow and solid shafts depends on specific operational demands such as load capacity, weight constraints, and manufacturing costs.

Material Composition and Manufacturing

Hollow shafts typically use high-strength alloy steels or composites to balance lightweight properties and durability, while solid shafts are often made from carbon steel or stainless steel for maximum strength and rigidity. Manufacturing hollow shafts involves processes like extrusion, tube drawing, or machining from a hollow billet, contributing to reduced weight without sacrificing performance. Solid shafts are generally produced through forging, turning, or grinding, ensuring uniform material density and maximum torsional strength.

Strength and Structural Integrity

Hollow shafts offer a superior strength-to-weight ratio compared to solid shafts, providing enhanced torsional rigidity while reducing overall mass. The distribution of material away from the center in hollow shafts increases their resistance to bending and twisting stresses, maintaining structural integrity under dynamic loads. Solid shafts, though generally stronger in pure compressive strength, are heavier and less efficient in applications requiring high strength with minimal weight.

Weight and Mass Considerations

Hollow shafts provide significant weight reduction compared to solid shafts while maintaining comparable strength, making them ideal for applications requiring lower mass without sacrificing performance. The decreased weight results in improved rotational inertia and reduced energy consumption in machinery or vehicles. Despite a slightly larger diameter, hollow shafts offer better material efficiency, enabling optimal mass distribution and enhanced dynamic balance.

Torsional Rigidity and Resistance

Hollow shafts typically offer higher torsional rigidity relative to their weight compared to solid shafts due to the distribution of material farther from the center, enhancing resistance to twisting forces. Solid shafts, while generally heavier, provide greater overall torsional strength and are less prone to buckling under compressive loads. In applications demanding lightweight design with efficient torque transmission, hollow shafts provide superior torsional resistance-to-weight ratios, whereas solid shafts excel in durability and simple manufacturing.

Cost Efficiency and Economic Impact

Hollow shafts offer significant cost efficiency by reducing material usage and weight, leading to lower manufacturing and transportation expenses compared to solid shafts. The economic impact of hollow shafts includes decreased energy consumption during operation thanks to their lighter mass, which translates to long-term savings in industrial applications. Solid shafts, while sometimes more economical upfront, incur higher costs over time due to increased material and maintenance requirements.

Application Suitability: Industry Uses

Hollow shafts are predominantly used in automotive and aerospace industries due to their high strength-to-weight ratio, enabling efficient torque transmission with reduced mass. Solid shafts find extensive application in heavy machinery and construction equipment where maximum durability and resistance to torsion are critical. Manufacturing sectors choose hollow shafts for robotics and conveyor systems to optimize performance through lighter rotating parts, while solid shafts suit hydraulic and power transmission systems requiring robust, shock-resistant components.

Maintenance and Durability Factors

Hollow shafts typically require less maintenance due to their lighter weight, reducing wear on bearings and supporting structures, which enhances overall durability. Solid shafts, while heavier and potentially more prone to stress and fatigue, offer higher torsional strength and resistance to deformation under heavy loads. Proper lubrication, regular inspection for cracks or corrosion, and adherence to load limits are critical maintenance practices that extend the lifespan of both hollow and solid shafts in mechanical systems.

Performance in Dynamic Conditions

Hollow shafts provide superior performance in dynamic conditions due to their lower rotational inertia, enabling faster acceleration and deceleration compared to solid shafts. Their reduced mass while maintaining similar strength improves torque response and vibration damping, enhancing operational stability at high speeds. Solid shafts, although stronger in torsion, often struggle with increased stress concentrations under dynamic loads, leading to potential fatigue failures in high-speed applications.

Choosing the Right Shaft for Your Needs

Hollow shafts offer a lighter weight solution with improved torque-to-weight ratio, making them ideal for applications requiring reduced inertia and increased speed, such as in automotive and aerospace industries. Solid shafts provide higher strength and durability, suitable for heavy-duty applications where maximum load capacity and resistance to bending are critical, like in machinery and structural equipment. Selecting the right shaft depends on factors including weight constraints, torque requirements, and the specific mechanical environment of the application.

Hollow shaft Infographic

libterm.com

libterm.com