Heat exchangers efficiently transfer thermal energy between fluids, optimizing industrial processes and improving energy conservation. Their design varies from shell-and-tube to plate and fin types, each tailored for specific temperature and pressure requirements. Discover how selecting the right heat exchanger can enhance your system's performance in the following article.

Table of Comparison

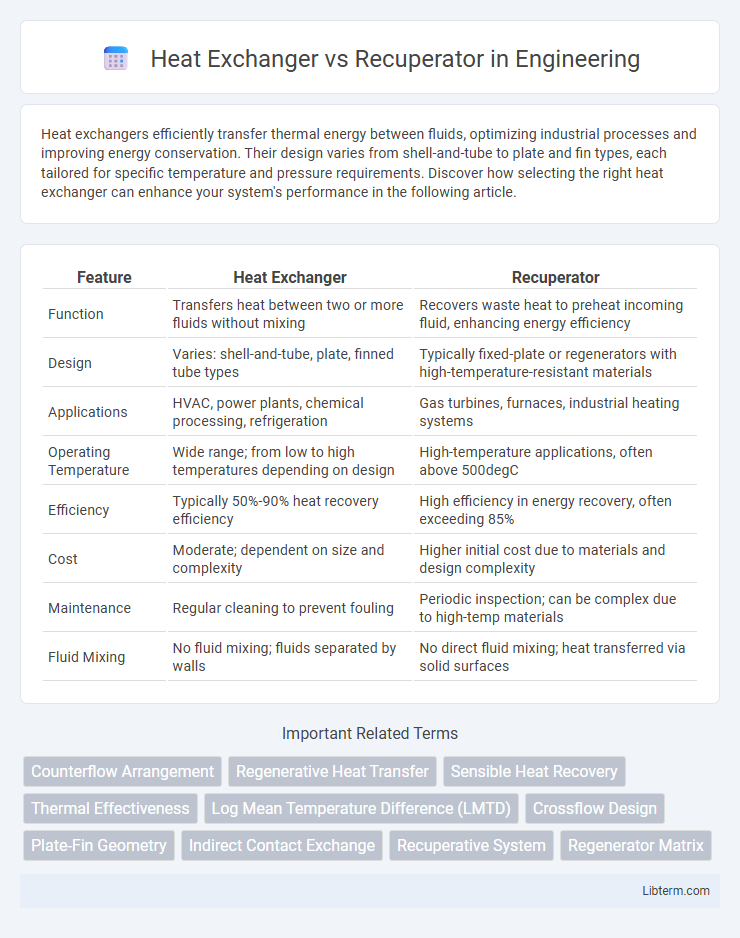

| Feature | Heat Exchanger | Recuperator |

|---|---|---|

| Function | Transfers heat between two or more fluids without mixing | Recovers waste heat to preheat incoming fluid, enhancing energy efficiency |

| Design | Varies: shell-and-tube, plate, finned tube types | Typically fixed-plate or regenerators with high-temperature-resistant materials |

| Applications | HVAC, power plants, chemical processing, refrigeration | Gas turbines, furnaces, industrial heating systems |

| Operating Temperature | Wide range; from low to high temperatures depending on design | High-temperature applications, often above 500degC |

| Efficiency | Typically 50%-90% heat recovery efficiency | High efficiency in energy recovery, often exceeding 85% |

| Cost | Moderate; dependent on size and complexity | Higher initial cost due to materials and design complexity |

| Maintenance | Regular cleaning to prevent fouling | Periodic inspection; can be complex due to high-temp materials |

| Fluid Mixing | No fluid mixing; fluids separated by walls | No direct fluid mixing; heat transferred via solid surfaces |

Introduction to Heat Exchanger and Recuperator

Heat exchangers are devices designed to transfer heat efficiently between two or more fluids without mixing them, commonly used in HVAC, power plants, and chemical processing. Recuperators are a specific type of heat exchanger that recover waste heat from exhaust gases to preheat incoming air or fluid, enhancing energy efficiency in industrial applications. Understanding the operational differences and applications of heat exchangers and recuperators is crucial for optimizing thermal management and reducing energy consumption.

Core Differences Between Heat Exchanger and Recuperator

Heat exchangers transfer thermal energy between two or more fluids without mixing them, commonly used in HVAC, power plants, and chemical processing. Recuperators are a specific type of heat exchanger designed to capture and recycle waste heat from exhaust gases to preheat incoming air or fluids, improving overall system efficiency. The core difference lies in their application: heat exchangers serve a broad range of heat transfer needs, while recuperators focus primarily on energy recovery in high-temperature processes.

Principles of Operation: Heat Exchanger vs Recuperator

Heat exchangers transfer thermal energy between two or more fluids at different temperatures without mixing them, using conduction and convection through a separating surface. Recuperators specifically recover waste heat from exhaust gases to preheat incoming air or fluid, enhancing system efficiency by recycling thermal energy. Both devices rely on maximizing surface area and thermal conductivity but differ in application focus--general heat transfer versus recuperative heat recovery.

Types of Heat Exchangers and Recuperators

Shell and tube, plate, and finned tube heat exchangers are common types used for efficient thermal transfer, with shell and tube exchangers suitable for high-pressure applications and plate exchangers offering compact heat transfer with high efficiency. Recuperators, often utilized in gas turbines and industrial furnaces, typically include fixed-plate and rotary wheel types, designed to recover waste heat from exhaust gases to preheat incoming air. The choice between a heat exchanger and a recuperator depends on factors such as operational temperature, pressure, and desired thermal efficiency in energy recovery systems.

Efficiency Comparison: Heat Exchanger vs Recuperator

Heat exchangers and recuperators both improve thermal efficiency by transferring heat between fluids, but recuperators are specifically designed for continuous, high-efficiency heat recovery in gas turbine and industrial applications. Recuperators typically achieve higher efficiency rates, often exceeding 80%, by capturing waste heat from exhaust gases and redirecting it to preheat incoming air or fluids, reducing fuel consumption. In contrast, conventional heat exchangers may have lower overall efficiency due to limitations in material conductivity and design, making recuperators a superior choice for optimizing energy savings in high-temperature processes.

Applications in Industry

Heat exchangers and recuperators are critical in industrial applications for enhancing energy efficiency and process optimization. Heat exchangers transfer thermal energy between fluids in power plants, chemical processing, HVAC systems, and food manufacturing, enabling temperature control and energy recovery. Recuperators, a specific type of heat exchanger often used in metal production, glass manufacturing, and gas turbines, recover waste heat from exhaust gases to preheat incoming air, substantially reducing fuel consumption and emissions.

Advantages and Disadvantages

Heat exchangers provide efficient thermal energy transfer between two fluids without mixing, offering high versatility and suitability for various industrial applications, but they may experience fouling and require regular maintenance. Recuperators, designed to recover waste heat from exhaust gases to preheat incoming air, improve energy efficiency and reduce fuel consumption but often have higher initial costs and can be susceptible to corrosion and temperature limitations. Both technologies enhance energy savings; selecting the optimal device depends on factors such as operating temperatures, fluid compatibility, and cost considerations.

Selection Criteria for Each System

Heat exchanger selection depends on factors such as temperature range, fluid compatibility, and heat transfer efficiency, favoring shell and tube or plate designs for versatile industrial applications. Recuperators are chosen for high-temperature gas-to-gas heat recovery, often in turbine or furnace exhaust systems, prioritizing pressure drop minimization and material durability under corrosive conditions. Optimal selection hinges on the application's thermal load, fluid properties, and economic considerations to maximize energy recovery and operational lifespan.

Maintenance and Durability Considerations

Heat exchangers require regular cleaning and inspection to prevent fouling and corrosion, which can degrade heat transfer efficiency and lead to premature failure. Recuperators, often made from high-grade alloys resistant to thermal stress and oxidation, typically offer longer durability but demand specialized maintenance to address potential cracking due to cyclic temperature fluctuations. Selecting between the two involves evaluating maintenance accessibility, material resilience, and operational lifespan to ensure optimal performance in industrial applications.

Future Trends in Heat Recovery Technologies

Future trends in heat recovery technologies emphasize advanced materials and smart design integration to enhance efficiency in heat exchangers and recuperators. Innovations such as additive manufacturing enable complex geometries that optimize heat transfer while minimizing pressure drop, crucial for energy-intensive industries. Emerging developments also include adaptive control systems and corrosion-resistant alloys that extend equipment lifespan and reduce maintenance costs.

Heat Exchanger Infographic

libterm.com

libterm.com