Surge pressure occurs when a fluid in motion is forced to stop or change direction suddenly, causing a rapid increase in pressure within pipes or systems. This phenomenon can lead to pipe bursts, equipment damage, and costly downtime if not properly managed. Discover effective strategies to protect your systems from surge pressure damage in the following article.

Table of Comparison

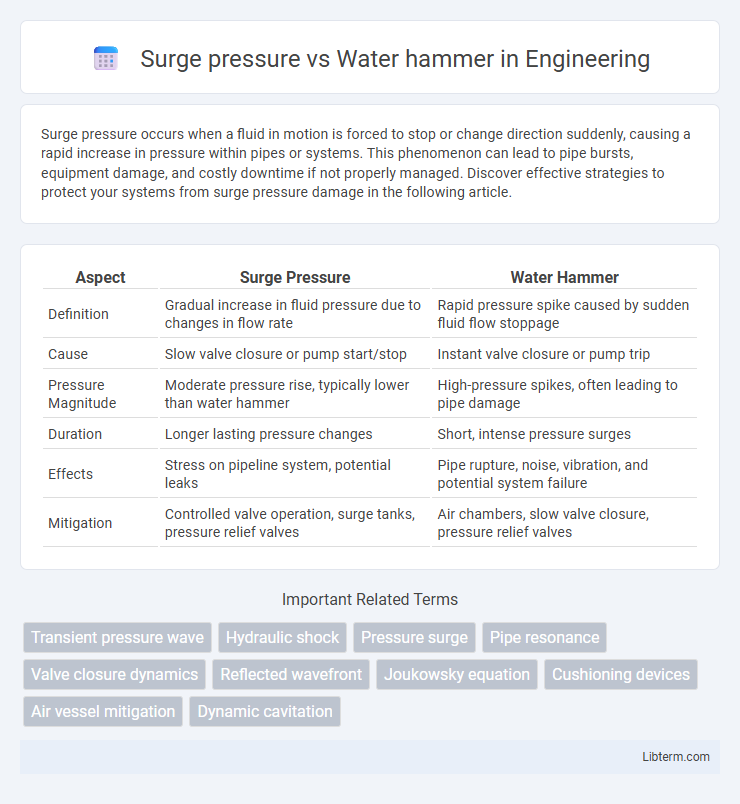

| Aspect | Surge Pressure | Water Hammer |

|---|---|---|

| Definition | Gradual increase in fluid pressure due to changes in flow rate | Rapid pressure spike caused by sudden fluid flow stoppage |

| Cause | Slow valve closure or pump start/stop | Instant valve closure or pump trip |

| Pressure Magnitude | Moderate pressure rise, typically lower than water hammer | High-pressure spikes, often leading to pipe damage |

| Duration | Longer lasting pressure changes | Short, intense pressure surges |

| Effects | Stress on pipeline system, potential leaks | Pipe rupture, noise, vibration, and potential system failure |

| Mitigation | Controlled valve operation, surge tanks, pressure relief valves | Air chambers, slow valve closure, pressure relief valves |

Understanding Surge Pressure: Definition and Causes

Surge pressure refers to a sudden increase in pressure within a fluid system, often triggered by rapid changes in flow velocity such as valve closures or pump startups. This phenomenon causes a transient pressure wave that propagates through pipelines, potentially leading to equipment damage or pipe bursts. Understanding the causes of surge pressure is critical for designing appropriate mitigation measures to ensure system integrity and operational safety.

Water Hammer Explained: Key Concepts and Mechanisms

Water hammer is a pressure surge caused by the sudden change in fluid velocity within a pipeline, often resulting from rapid valve closure or pump shutdown. This phenomenon generates shock waves that propagate through the fluid, leading to potential pipe damage or system failure. Understanding the mechanisms of water hammer involves analyzing fluid momentum, pipe elasticity, and transient pressure variations to design effective mitigation strategies.

Surge Pressure vs Water Hammer: Core Differences

Surge pressure and water hammer both involve sudden changes in fluid pressure within a pipeline, but surge pressure typically refers to a gradual increase due to changes like pump startup or shutdown. Water hammer is a rapid pressure spike caused by abrupt valve closure or sudden flow stoppage, generating shock waves. The core difference lies in the speed and cause of pressure change: surge pressure develops more slowly, while water hammer is an instantaneous, high-magnitude pressure transient.

Common Triggers for Surge Pressure Events

Surge pressure and water hammer both result from rapid changes in fluid velocity within pipelines, causing intense pressure waves. Common triggers for these surge pressure events include sudden valve closures, pump startups or shutdowns, and abrupt changes in flow rate. These transient conditions create high-pressure spikes that can damage pipes and disrupt system performance.

How Water Hammer Develops in Piping Systems

Water hammer develops in piping systems when a sudden change in fluid velocity, often caused by rapid valve closure or pump failure, generates a pressure surge that propagates as a pressure wave. This transient pressure spike, much higher than normal operating pressures, can cause pipe deformation, joint damage, and even system failure. Unlike general surge pressure, water hammer specifically refers to the dynamic pressure wave resulting from fluid momentum abruptly stopping or changing direction within the pipe network.

Impacts of Surge Pressure on Infrastructure

Surge pressure causes sudden spikes in pipeline pressure, leading to structural stress, joint failures, and potential ruptures in water distribution systems. Water hammer, a rapid pressure fluctuation caused by quick valve closures, intensifies these impacts by generating shock waves that damage pipes and fittings. Effective surge protection devices and pressure management are essential to prevent costly infrastructure damage and ensure system longevity.

Consequences of Water Hammer in Industrial Applications

Water hammer leads to sudden pressure surges that can exceed pipeline design limits, causing significant mechanical stress and potential rupture in industrial systems. These pressure spikes generate vibrations and noise, resulting in fatigue damage to valves, pumps, and pipe supports, thereby reducing equipment lifespan. Consequences include costly downtime, safety hazards, and increased maintenance requirements in industries such as oil and gas, chemical processing, and power generation.

Preventing Surge Pressure: Effective Strategies

Surge pressure and water hammer both result from sudden changes in fluid velocity, causing pressure spikes that can damage pipelines and equipment. Preventing surge pressure involves installing surge tanks, pressure relief valves, and air chambers to absorb shock waves and maintain steady flow. Implementing controlled valve operations and using variable-speed pumps further reduces the risk of water hammer by minimizing rapid pressure fluctuations in piping systems.

Water Hammer Mitigation Techniques and Devices

Water hammer mitigation techniques include installing air chambers, surge tanks, and pressure relief valves to absorb shock waves caused by sudden fluid velocity changes. Devices such as slow-closing valves and variable speed pumps help minimize pressure surges by controlling flow rate transitions smoothly. Proper pipe design, including adequate anchoring and use of flexible joints, further reduces the risk and impact of water hammer in hydraulic systems.

Surge Pressure and Water Hammer: Safety and Maintenance Considerations

Surge pressure and water hammer both pose significant risks to piping systems, potentially causing pipe bursts, joint failures, and equipment damage due to sudden pressure changes. Implementing pressure relief valves, air chambers, and regular maintenance checks are critical to mitigate these effects and ensure system safety. Proper design and monitoring help prevent costly repairs and extend the lifespan of pipelines in industrial and municipal water supply systems.

Surge pressure Infographic

libterm.com

libterm.com