Forming is a crucial manufacturing process that shapes raw materials into desired components by applying force without removing material. This technique enhances material properties and allows for cost-effective production of complex shapes used in various industries. Explore the rest of the article to understand different forming methods and their applications.

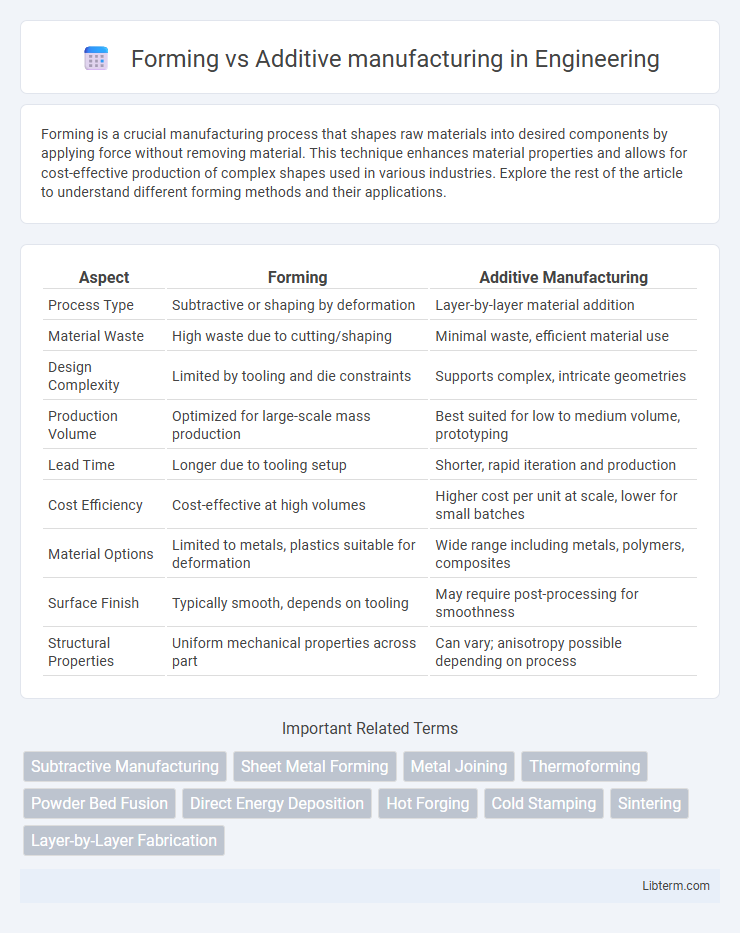

Table of Comparison

| Aspect | Forming | Additive Manufacturing |

|---|---|---|

| Process Type | Subtractive or shaping by deformation | Layer-by-layer material addition |

| Material Waste | High waste due to cutting/shaping | Minimal waste, efficient material use |

| Design Complexity | Limited by tooling and die constraints | Supports complex, intricate geometries |

| Production Volume | Optimized for large-scale mass production | Best suited for low to medium volume, prototyping |

| Lead Time | Longer due to tooling setup | Shorter, rapid iteration and production |

| Cost Efficiency | Cost-effective at high volumes | Higher cost per unit at scale, lower for small batches |

| Material Options | Limited to metals, plastics suitable for deformation | Wide range including metals, polymers, composites |

| Surface Finish | Typically smooth, depends on tooling | May require post-processing for smoothness |

| Structural Properties | Uniform mechanical properties across part | Can vary; anisotropy possible depending on process |

Introduction to Forming and Additive Manufacturing

Forming manufacturing involves shaping materials through deformation processes such as forging, rolling, bending, and extrusion, utilizing mechanical force to alter the material's geometry without adding or removing material. Additive manufacturing, commonly known as 3D printing, builds objects layer-by-layer directly from digital models, enabling complex geometries and reduced material waste. Both methods serve distinct industrial applications, with forming excelling in high-volume production of metal parts and additive manufacturing providing rapid prototyping and customization capabilities.

Core Principles of Forming Processes

Forming processes involve reshaping materials through plastic deformation without adding or removing material, relying on principles such as stress, strain, and material flow behavior under controlled temperature and pressure conditions. Techniques like rolling, forging, and extrusion exemplify core forming methods where the material's microstructure and mechanical properties are refined through deformation. Unlike additive manufacturing, which builds components layer-by-layer from raw material, forming emphasizes altering the geometry of existing solid workpieces to achieve desired shapes and performance characteristics.

Fundamentals of Additive Manufacturing Technologies

Additive manufacturing builds objects layer by layer directly from digital models, enabling complex geometries and material efficiency that traditional forming methods cannot achieve. Key technologies include powder bed fusion, material extrusion, and directed energy deposition, each using distinct energy sources and feedstock materials to selectively fuse or deposit material. These processes minimize waste and allow rapid prototyping, reducing lead times and enhancing design flexibility across industries such as aerospace and medical devices.

Material Compatibility in Forming vs Additive Manufacturing

Forming processes, such as forging and rolling, primarily work with metals and alloys that exhibit high ductility and malleability to withstand deformation without cracking. Additive manufacturing offers broader material compatibility, including metals, polymers, ceramics, and composites, enabling the production of complex geometries and functionally graded materials that are difficult or impossible to achieve through traditional forming. Material selection in additive manufacturing is influenced by factors like powder or filament availability, melting behavior, and layer adhesion, whereas forming relies on the feedstock's ability to maintain structural integrity under mechanical stress.

Process Workflow Comparison

Forming manufacturing involves shaping raw materials through deformation processes like forging, rolling, or extrusion, primarily working with solid metals and requiring significant force and tooling setup. Additive manufacturing builds objects layer-by-layer from digital models using materials like polymers, metals, or composites, enabling complex geometries and reducing material waste. The workflow in forming is largely linear and batch-oriented with long lead times, whereas additive manufacturing offers greater flexibility with rapid prototyping and on-demand production.

Design Flexibility and Complexity Capabilities

Forming processes typically have limited design flexibility due to reliance on molds and dies, restricting complexity and customization options. Additive manufacturing excels in producing intricate geometries and complex internal structures not achievable with traditional forming methods. This layer-by-layer fabrication enables rapid prototyping and highly customized production with minimal material waste.

Cost Efficiency and Economic Considerations

Forming processes typically offer lower per-unit costs for large production runs due to economies of scale and established workflow efficiencies. Additive manufacturing incurs higher material and machine operation costs but provides economic advantages in low-volume production, customization, and rapid prototyping. Cost efficiency in manufacturing method selection hinges on production volume, design complexity, and material utilization rates.

Surface Finish and Dimensional Accuracy

Forming processes typically achieve superior surface finish and higher dimensional accuracy due to controlled material deformation and precision tooling. Additive manufacturing often results in rougher surfaces and lower dimensional precision because of layer-by-layer material deposition and possible anisotropy effects. Post-processing is commonly required in additive manufacturing to enhance surface quality and meet strict dimensional tolerances.

Sustainability and Environmental Impact

Forming manufacturing techniques generally consume more raw materials and generate higher waste compared to additive manufacturing, which builds objects layer-by-layer with precise material usage, minimizing scrap. Additive manufacturing significantly reduces energy consumption through shorter production cycles and localized fabrication, lowering the carbon footprint relative to traditional forming processes. Lifecycle assessments reveal additive manufacturing's potential for sustainable production by enabling lightweight designs and efficient resource utilization, crucial for reducing environmental impact in industries such as aerospace and automotive.

Future Trends in Forming and Additive Manufacturing

Future trends in forming emphasize increased automation and integration with advanced sensors to enhance precision and reduce waste in metal forming and forging processes. Additive manufacturing continues to evolve through multi-material printing, enhanced speed, and scalability, enabling complex geometries and functional integration in aerospace and biomedical applications. Hybrid manufacturing systems combining forming and additive techniques are gaining traction, offering improved mechanical properties and design flexibility for next-generation manufacturing.

Forming Infographic

libterm.com

libterm.com