Thermoelectric cooling uses the Peltier effect to transfer heat from one side of a device to another, providing efficient and compact temperature control without moving parts. This solid-state technology is ideal for applications requiring reliability, precise temperature regulation, and silent operation. Discover how thermoelectric cooling can enhance your systems by reading the rest of the article.

Table of Comparison

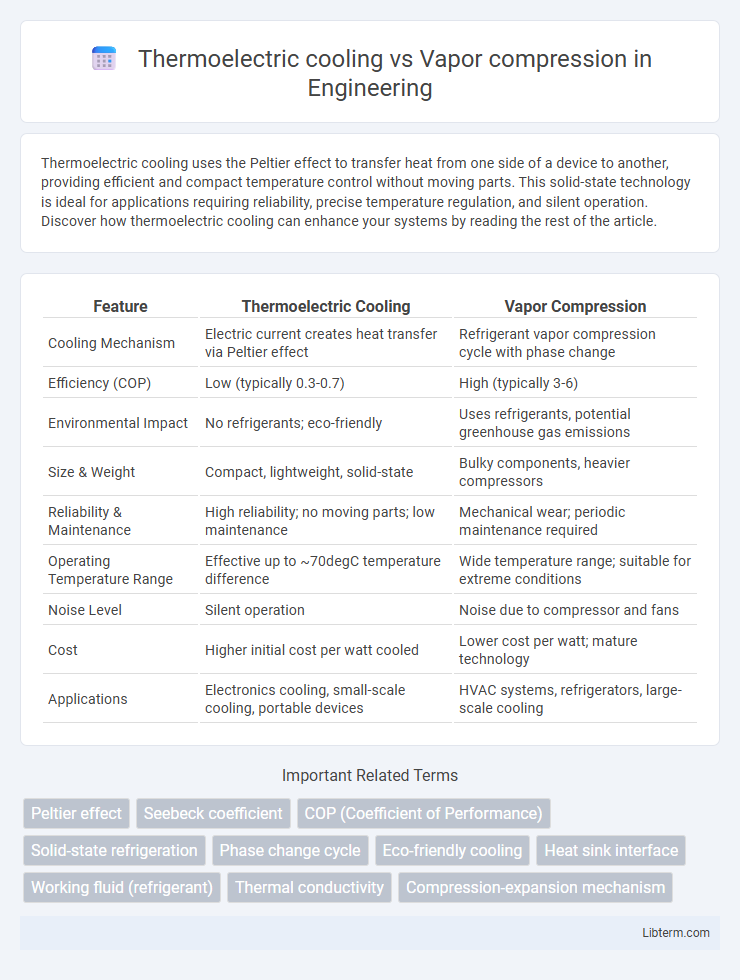

| Feature | Thermoelectric Cooling | Vapor Compression |

|---|---|---|

| Cooling Mechanism | Electric current creates heat transfer via Peltier effect | Refrigerant vapor compression cycle with phase change |

| Efficiency (COP) | Low (typically 0.3-0.7) | High (typically 3-6) |

| Environmental Impact | No refrigerants; eco-friendly | Uses refrigerants, potential greenhouse gas emissions |

| Size & Weight | Compact, lightweight, solid-state | Bulky components, heavier compressors |

| Reliability & Maintenance | High reliability; no moving parts; low maintenance | Mechanical wear; periodic maintenance required |

| Operating Temperature Range | Effective up to ~70degC temperature difference | Wide temperature range; suitable for extreme conditions |

| Noise Level | Silent operation | Noise due to compressor and fans |

| Cost | Higher initial cost per watt cooled | Lower cost per watt; mature technology |

| Applications | Electronics cooling, small-scale cooling, portable devices | HVAC systems, refrigerators, large-scale cooling |

Introduction to Thermoelectric Cooling and Vapor Compression

Thermoelectric cooling utilizes the Peltier effect, where an electric current induces heat transfer across semiconductor materials, offering solid-state refrigeration without moving parts or refrigerants. Vapor compression systems rely on a refrigerant cycle involving evaporation and condensation to absorb and dissipate heat, delivering efficient cooling for a wide range of applications. Both technologies differ fundamentally in mechanism, efficiency, and application scope, with thermoelectric coolers excelling in compact and noise-sensitive environments, while vapor compression dominates large-scale cooling due to higher efficiency.

How Thermoelectric Cooling Works

Thermoelectric cooling operates based on the Peltier effect, where an electric current passes through two different semiconductor materials, creating a heat flux that moves heat from one side of the device to the other. This solid-state process eliminates the need for compressors or refrigerants, resulting in quieter, more compact cooling units with no moving parts. Thermoelectric coolers offer precise temperature control and higher reliability compared to traditional vapor compression systems, which rely on phase change of refrigerants and mechanical compression cycles.

Principles of Vapor Compression Refrigeration

Vapor compression refrigeration operates on the principles of compression, condensation, expansion, and evaporation to transfer heat efficiently. The refrigerant absorbs heat during evaporation at low pressure and temperature, then releases it during condensation at high pressure and temperature, enabling effective cooling in systems such as air conditioners and refrigerators. This cycle contrasts with thermoelectric cooling, which relies on the Peltier effect and typically offers lower efficiency and cooling capacity.

Energy Efficiency Comparison

Thermoelectric cooling systems typically exhibit lower energy efficiency compared to vapor compression systems due to higher electrical power consumption for equivalent cooling output. Vapor compression units leverage phase change of refrigerants to transfer heat more effectively, achieving Coefficients of Performance (COP) ranging from 3 to 6, while thermoelectric coolers often have COP values below 1.5, resulting in higher operational costs and greater energy use in large-scale applications.

Cooling Capacity and Performance Differences

Thermoelectric cooling systems typically offer lower cooling capacity compared to vapor compression systems, making them suitable for small-scale or specialized applications. Vapor compression units provide higher cooling efficiency and greater cooling power, often measured in BTUs or kilowatts, suitable for large-scale refrigeration and air conditioning. Performance differences highlight thermoelectric coolers' solid-state reliability and quiet operation against vapor compressors' higher coefficient of performance (COP) and widespread industrial use.

Environmental Impact: Greenhouse Gases and Sustainability

Thermoelectric cooling systems operate without refrigerants, eliminating greenhouse gas emissions associated with vapor compression technologies that rely on hydrofluorocarbons (HFCs), potent contributors to global warming. Thermoelectric devices use solid-state components, enhancing sustainability by reducing reliance on harmful chemicals and enabling longer product lifespans with lower energy consumption. Vapor compression systems, while efficient, pose environmental risks through refrigerant leaks and require complex recycling protocols to mitigate their impact on ozone depletion and climate change.

Size, Flexibility, and Application Versatility

Thermoelectric cooling systems are compact and lightweight, offering greater design flexibility for small-scale or portable applications, unlike vapor compression units which are bulkier due to mechanical components. The solid-state nature of thermoelectric coolers allows precise temperature control and silent operation, making them ideal for electronics or specialized medical devices, whereas vapor compression systems are preferred for large-scale refrigeration and HVAC due to higher efficiency in cooling capacity. Application versatility favors vapor compression in commercial and industrial uses, while thermoelectric coolers excel in niche markets where size, noise, and maintenance are critical factors.

Noise Levels and Maintenance Requirements

Thermoelectric cooling systems operate silently due to the absence of moving parts, making them ideal for noise-sensitive environments, whereas vapor compression units generate noticeable noise from compressors and fans. Maintenance for thermoelectric coolers is minimal, primarily limited to occasional cleaning, while vapor compression systems require regular maintenance including refrigerant checks, compressor servicing, and potential leak repairs. Noise reduction and lower upkeep costs make thermoelectric cooling favorable for small-scale, quiet applications, contrasting with the higher noise levels and complex maintenance of vapor compression cooling.

Cost Analysis: Initial Investment and Operating Expenses

Thermoelectric cooling systems typically have a higher initial investment cost due to expensive semiconductor materials and low scalability, whereas vapor compression units are more affordable upfront with mass-produced components. Operating expenses for thermoelectric cooling are generally lower because they have fewer moving parts, require minimal maintenance, and can operate silently with no refrigerants, unlike vapor compression systems which incur costs from refrigerant replenishment and regular compressor servicing. Over the lifespan, vapor compression systems may incur higher energy costs due to compressor inefficiency, while thermoelectric units offer energy savings but at the expense of lower cooling capacity.

Choosing the Right Technology for Your Application

Thermoelectric cooling excels in compact, energy-efficient applications requiring precise temperature control and silent operation, making it ideal for electronics and portable devices. Vapor compression systems deliver higher cooling capacity and efficiency for large-scale refrigeration and air conditioning needs, excelling in industrial or commercial setups. Selecting the right technology depends on factors like cooling load, energy consumption, size constraints, and noise sensitivity to optimize performance and cost-effectiveness.

Thermoelectric cooling Infographic

libterm.com

libterm.com